10 Essential Facts About Q275 Steel You Must Know

Table of Contents

Introduction

Q275 steel is a widely used material in various industries due to its excellent mechanical properties and cost-effectiveness. Whether you’re in construction, manufacturing, or engineering, understanding the characteristics and applications of this material can help you make informed decisions for your projects. In this blog, we’ll explore ten essential facts about Q275 steel, from its composition to its advantages and limitations. By the end, you’ll have a comprehensive understanding of why this material is a popular choice for professionals worldwide.

What is Q275 Steel?

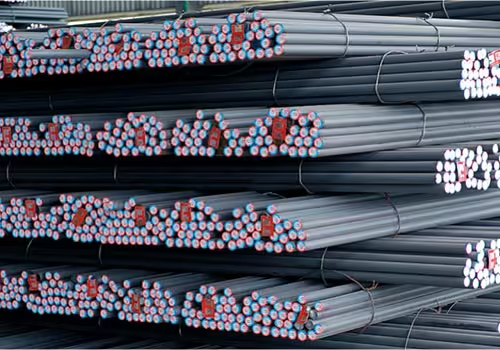

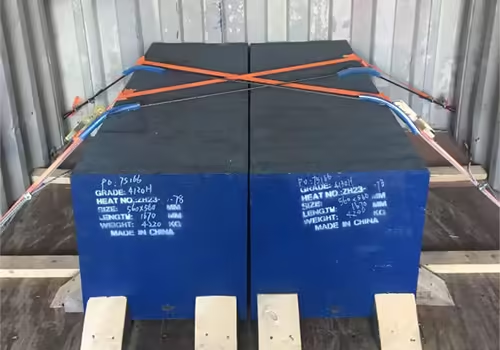

Q275 steel is a type of carbon structural steel that adheres to the Chinese GB/T 700 standard. Renowned for its balanced combination of moderate strength, excellent ductility, and superior weldability, this material is highly versatile and widely utilized across various industries. It is particularly favored in the construction sector for building frameworks, bridges, and other infrastructure projects. Additionally, its properties make it a reliable option for manufacturing machinery and other structural components that require durability and ease of fabrication.

The chemical composition of this steel includes essential elements such as carbon, manganese, silicon, phosphorus, and sulfur. These elements are carefully balanced to enhance the material’s mechanical properties, ensuring it can withstand significant stress and deformation without failure. With a tensile strength ranging from 410 to 560 MPa and a yield strength of 275 MPa, it offers a robust performance that meets the demands of many engineering applications. Its elongation at break, approximately 21%, further underscores its ductility, allowing it to absorb energy and resist fracturing under load.

One of the standout features of this steel grade is its excellent weldability. It can be easily welded using common methods such as arc welding, gas welding, and resistance welding, making it an ideal choice for projects that involve extensive joining processes. This characteristic not only simplifies construction but also ensures strong and durable connections in the final structure.

In terms of cost-effectiveness, this material is more economical compared to higher-grade steels, yet it still provides sufficient strength for many applications. This affordability, combined with its reliable performance, makes it a popular choice for large-scale projects where budget considerations are paramount.

Overall, this carbon structural steel is a dependable and versatile material that meets a broad spectrum of engineering and construction needs. Its well-rounded properties, including strength, ductility, weldability, and cost-efficiency, make it a preferred option for professionals seeking a robust and practical solution for their structural and mechanical requirements.

10 Essential Facts About Q275 Steel

1. Chemical Composition

This material is composed of a balanced mix of carbon, manganese, silicon, phosphorus, and sulfur. The specific proportions of these elements are carefully controlled to enhance the alloy’s strength and durability while ensuring it remains easy to work with during fabrication.

2. Mechanical Properties

The alloy exhibits a tensile strength ranging from 410 to 560 MPa, with a yield strength of 275 MPa. Its elongation at break is around 21%, indicating good ductility. This means it can undergo significant deformation before fracturing, making it suitable for applications requiring flexibility and resilience.

3. Weldability

One of the standout characteristics of this steel grade is its excellent weldability. It can be efficiently joined using common techniques such as arc welding, gas welding, and resistance welding. This property makes it a preferred choice for structural applications where welding is a critical process.

4. Cost-Effectiveness

When compared to higher-grade steels, this material is more economical while still offering adequate strength for various uses. Its affordability makes it an attractive option for large-scale projects where cost efficiency is a priority.

5. Versatility in Applications

Due to its balanced properties, this steel is versatile and can be used in a wide range of applications. From construction to manufacturing, it serves as a reliable material for different structural and mechanical components.

6. Corrosion Resistance

While not inherently corrosion-resistant, this alloy can be treated or coated to improve its resistance to environmental factors. This makes it suitable for use in environments where exposure to moisture or chemicals is a concern.

7. Machinability

The material is known for its good machinability, allowing it to be easily cut, shaped, and formed into desired configurations. This ease of machining reduces production time and costs, further enhancing its appeal for industrial applications.

8. Thermal Conductivity

This steel exhibits moderate thermal conductivity, making it suitable for applications where heat dissipation is necessary. Its ability to withstand thermal stress without significant degradation adds to its utility in various engineering contexts.

9. Environmental Impact

The production of this steel involves processes that can be optimized to reduce environmental impact. By using recycled materials and implementing energy-efficient manufacturing techniques, the ecological footprint of producing this alloy can be minimized.

10. Limitations

This steel grade conforms to international standards, ensuring consistent quality and performance. Adherence to these specifications guarantees that the material meets the necessary requirements for safety and reliability in its intended applications.

Applications

This material is widely used in the following industries:

- Construction: Beams, columns, and frameworks

- Automotive: Chassis and structural components

- Machinery: Frames and supports

- Infrastructure: Bridges and railings

Its versatility and reliability make it a preferred choice for engineers and architects.

Comparison with Other Grades

| Property | Q235 Steel | Q275 Steel | Q345 Steel |

|---|---|---|---|

| Tensile Strength (MPa) | 370-500 | 410-560 | 470-630 |

| Yield Strength (MPa) | 235 | 275 | 345 |

| Elongation (%) | 26 | 21 | 22 |

| Weldability | Excellent | Excellent | Good |

| Cost | Low | Moderate | High |

Conclusion

Q275 steel is a versatile and cost-effective material that offers a balance of strength, ductility, and weldability. Its wide range of applications and ease of fabrication make it a popular choice for professionals in construction, manufacturing, and engineering. By understanding its properties and limitations, you can make informed decisions to ensure the success of your projects.

FAQ

What is Q275 steel used for?

Q275 steel is commonly used in construction, automotive, machinery, and infrastructure projects due to its strength and versatility.

How does Q275 steel compare to Q235 steel?

Q275 steel has higher tensile and yield strength than Q235 steel but slightly lower elongation. Both grades offer excellent weldability and cost-effectiveness.

Can Q275 steel be welded?

Yes, Q275 steel is known for its excellent weldability and can be welded using common methods such as arc welding and gas welding.

Is Q275 steel corrosion-resistant?

While not inherently corrosion-resistant, Q275 steel can be treated with coatings or galvanization to improve its durability in harsh environments.

What are the limitations of Q275 steel?

Q275 steel is not suitable for high-stress applications that require ultra-high strength or extreme corrosion resistance. Understanding its limitations is essential for proper material selection.