10 Reasons Why 1020 Mild Steel Is Essential

Table of Contents

Introduction

In the realm of materials used in various industries, 1020 mild steel has gained recognition for its versatility and essential properties. This low carbon steel alloy is composed primarily of iron and a small amount of carbon, making it suitable for a wide range of applications. Its combination of affordability, workability, and strength makes 1020 mild steel an invaluable choice for engineers and manufacturers alike. In this blog post, we will explore ten compelling reasons why 1020 mild steel is essential in today’s industrial landscape.

Henan Jiyuan Iron and Steel (Group) Co., Ltd. was founded in 1958. It has rich experience in production and research and development. It provides you with one-stop steel services and welcomes consultations from customers around the world.

Understanding It

Composition and Properties

1020 mild steel is defined by its carbon content, which typically ranges from 0.15% to 0.25%. This low carbon content contributes to its excellent ductility and malleability, allowing it to be easily shaped and formed into various products. Additionally, 1020 mild steel exhibits good weldability, making it a preferred material for structural applications.

Mechanical Properties

When discussing the mechanical properties of it

, it’s essential to note its tensile strength, yield strength, and hardness. The following table provides a general overview of these properties, which highlight why this material is favored in many engineering applications.

| Property | Value |

|---|---|

| Tensile Strength | 350 MPa |

| Yield Strength | 200 MPa |

| Hardness (Brinell) | 130 HB |

| Elongation | 15% |

Applications of it

Structural Components

One of the most significant applications of it is in the construction of structural components. Its strength-to-weight ratio makes it ideal for beams, columns, and frames, providing the necessary support for buildings and bridges. The material’s ability to withstand various loads and stresses ensures structural integrity, making it a go-to choice for engineers.

Manufacturing and Fabrication

In manufacturing and fabrication, 1020 mild steel is widely used to create parts and components. Its excellent machinability allows it to be easily cut, drilled, and shaped into intricate designs. Whether it’s for automotive parts, machinery components, or general fabrication, 1020 mild steel offers reliability and performance.

Automotive Industry

The automotive industry relies heavily on 1020 mild steel for various applications, including chassis, body panels, and structural supports. Its ability to absorb energy during impacts enhances vehicle safety, while its cost-effectiveness contributes to affordable production.

Advantages of it

Cost-Effectiveness

One of the primary reasons for the widespread use of 1020 mild steel is its cost-effectiveness. Compared to other materials, such as stainless steel or aluminum, 1020 mild steel is relatively inexpensive, making it an attractive option for budget-conscious projects without compromising quality.

Ease of Welding

Welding is a critical process in many manufacturing operations, and 1020 mild steel’s excellent weldability simplifies this process. It can be easily joined using various welding techniques, including MIG, TIG, and stick welding, ensuring strong and reliable connections.

Availability

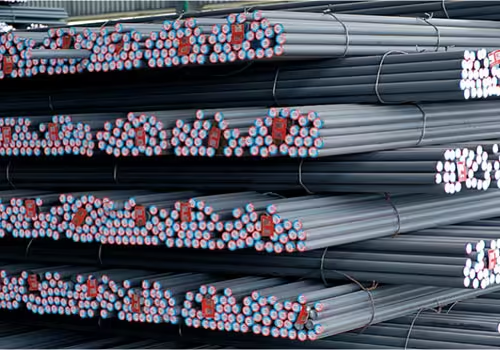

1020 mild steel is widely available in various forms, including sheets, plates, bars, and tubes. This availability makes it easy for manufacturers and fabricators to source the material for their projects, reducing lead times and enhancing productivity.

Environmental Impact and Sustainability

Recyclability

Another important aspect of 1020 mild steel is its recyclability. Steel is one of the most recycled materials globally, and 1020 mild steel can be repurposed without losing its properties. This characteristic contributes to sustainability efforts in manufacturing and construction, as recycled steel requires less energy to produce compared to virgin materials.

Lower Carbon Footprint

Utilizing 1020 mild steel can also help reduce the carbon footprint of various projects. Its production process generally involves fewer emissions compared to more specialized steels, making it a more environmentally friendly option for manufacturers seeking to minimize their impact on the planet.

Conclusion

In conclusion, 1020 mild steel is an essential material that offers numerous advantages across various industries. Its combination of strength, workability, cost-effectiveness, and recyclability makes it a preferred choice for engineers and manufacturers. From structural components to automotive applications, the versatility of 1020 mild steel is unmatched. As industries continue to evolve, this material will remain a cornerstone in manufacturing, contributing to the development of innovative products and sustainable practices.

FAQ

What is the carbon content of it?

The carbon content of 1020 mild steel typically ranges from 0.15% to 0.25%.

Is it weldable?

Yes, 1020 mild steel is known for its excellent weldability, making it suitable for various welding processes.

What are common applications of itl?

Common applications include structural components, automotive parts, and manufacturing and fabrication.

How does it compare to other types of steel?

1020 mild steel is more cost-effective than many specialized steels, making it a popular choice for projects requiring balance between quality and budget.

Can it be recycled?

Yes, 1020 mild steel is highly recyclable and contributes to sustainability efforts in manufacturing and construction.