1020 Steel Round Bar Applications

Introduction

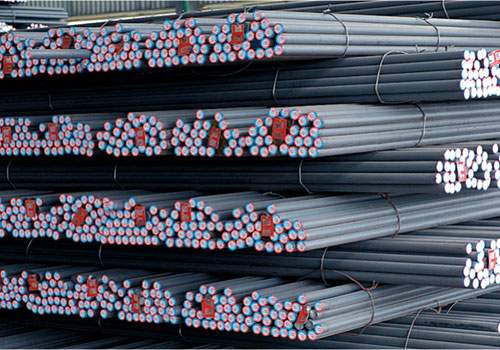

In the realm of metallurgy and engineering, the choice of materials is crucial for the success of any project. One such material that stands out for its versatility, strength, and cost-effectiveness is the 1020 steel round bar. This low-carbon steel grade is widely used in various industries due to its balanced mechanical properties, which make it ideal for applications that require a combination of strength, weldability, and machinability.

In this comprehensive guide, we will explore the various applications of 1020 steel round bar, its properties, and why it is a preferred choice for engineers and manufacturers alike. From automotive to construction, we’ll dive deep into the many ways in which 1020 steel round bar is utilized, and why it’s often the go-to material for structural components.

What is 1020 Steel Round Bar?

Properties and Composition of 1020 Steel Round Bar

1020 steel is a low-carbon steel grade, containing approximately 0.20% carbon, which gives it excellent machinability and weldability. The 1020 steel round bar is widely used because it strikes a balance between strength and flexibility, making it suitable for a range of applications in various industries.

- Carbon content: 0.18% – 0.23%

- Manganese content: 0.30% – 0.60%

- Tensile strength: 420 MPa

- Yield strength: 210 MPa

These properties allow the 1020 steel round bar to offer good formability and machinability while still providing enough strength to be useful in structural and mechanical applications. The low carbon content also ensures that it can be welded easily without the need for special treatments or techniques.

Key Benefits of 1020 Steel Round Bar

- Cost-Effective: 1020 steel round bar is relatively affordable compared to higher-carbon steels and other alloy steels.

- Easy to Machine: Its low carbon content makes it easier to cut, shape, and machine.

- Weldability: It can be welded using standard techniques, without requiring additional treatments.

- Moderate Strength: While not as strong as some high-carbon steels, 1020 steel round bar offers sufficient strength for many applications.

Common Applications of 1020 Steel Round Bar

Automotive Industry

In the automotive industry, 1020 steel round bar is widely used in the manufacturing of parts that require both strength and flexibility. It is often used in the production of components such as:

- Axles

- Gear shafts

- Crankshafts

- Engine components

The 1020 steel round bar is ideal for these applications because it can withstand the mechanical stresses imposed by moving parts, while its machinability allows for precision in shaping and fitting. Its weldability also ensures that components can be assembled efficiently.

Construction Industry

In construction, 1020 steel round bar is a popular choice for reinforcing concrete structures and creating foundational elements. It is used in applications such as:

- Rebar for concrete reinforcement

- Structural frameworks

- Support columns

The moderate strength and formability of 1020 steel round bar make it ideal for construction purposes, as it can be easily shaped to fit the specific needs of a project while providing adequate support.

Machinery and Equipment

In machinery and industrial equipment manufacturing, 1020 steel round bar is frequently used due to its ability to handle wear and tear. Applications in this area include:

- Machine shafts

- Hydraulic systems

- Gears and pinions

Its moderate tensile strength ensures that parts made from 1020 steel can endure repetitive use, while its weldability and machinability allow for ease of customization.

Table: Comparison of 1020 Steel Round Bar with Other Materials

The following table compares the properties of 1020 steel round bar with other commonly used materials in similar applications:

| Property | 1020 Steel Round Bar | 1045 Steel Round Bar | Stainless Steel 304 | Aluminum Alloy 6061 |

|---|---|---|---|---|

| Carbon Content (%) | 0.20 | 0.45 | <0.08 | N/A |

| Tensile Strength (MPa) | 420 | 585 | 515 | 276 |

| Yield Strength (MPa) | 210 | 310 | 215 | 241 |

| Weldability | Excellent | Good | Excellent | Excellent |

| Machinability | Excellent | Moderate | Poor | Excellent |

| Corrosion Resistance | Low | Low | High | High |

| Cost | Low | Moderate | High | Moderate |

As seen in the table, 1020 steel round bar offers an excellent balance between machinability, weldability, and strength compared to other materials. It is a cost-effective solution, particularly for applications where corrosion resistance is not a critical factor.

Advanced Uses of 1020 Steel Round Bar

Agricultural Equipment

The agricultural industry relies heavily on machinery that must endure harsh conditions and repeated use. 1020 steel round bar is used in the production of parts such as:

- Tractor components

- Plowshares

- Irrigation systems

The moderate strength and durability of 1020 steel round bar allow it to perform well in high-wear environments without needing frequent replacement, making it an economical choice for agricultural machinery.

Oil and Gas Industry

In the oil and gas sector, 1020 steel round bar is utilized for drilling components and mechanical systems that must withstand both pressure and wear. Its machinability allows for the precise manufacturing of:

- Drill bits

- Pumps

- Valve stems

Marine Industry

While not inherently corrosion-resistant, 1020 steel round bar can be treated to improve its performance in marine environments. It is often used in applications such as:

- Boat shafts

- Marine fasteners

- Structural reinforcements

The addition of protective coatings, such as galvanization, can significantly extend the lifespan of 1020 steel round bar in these environments.

Conclusion

The 1020 steel round bar is an exceptionally versatile material with applications across a wide range of industries. Its combination of moderate strength, excellent machinability, and weldability makes it a popular choice for both structural and mechanical uses. Whether in the automotive, construction, or agricultural sectors, 1020 steel round bar provides an economical solution without compromising on performance.

Understanding the specific applications and benefits of 1020 steel round bar can help engineers and manufacturers make informed decisions, ensuring that they choose the right material for their projects. Given its cost-effectiveness and widespread availability, 1020 steel round bar will continue to be a staple in industries requiring durable and adaptable steel components.

FAQ

What makes 1020 steel round bar different from higher-carbon steels?

The primary difference is its lower carbon content (approximately 0.20%), which makes it easier to machine and weld compared to higher-carbon steels. While it offers moderate strength, it does not harden as much through heat treatment as higher-carbon steels like 1045.

Can 1020 steel round bar be used in outdoor applications?

Yes, but it requires protective treatments such as galvanization or coatings to prevent rust and corrosion since it does not have inherent corrosion resistance.

What industries commonly use 1020 steel round bar?

Industries such as automotive, construction, machinery, agriculture, and oil & gas commonly use 1020 steel round bar for its versatility and ease of use in manufacturing.

How does 1020 steel round bar compare to stainless steel?

While stainless steel offers superior corrosion resistance, 1020 steel round bar is more cost-effective and easier to machine and weld. Stainless steel is typically used in environments where corrosion resistance is critical, while 1020 steel round bar is favored for general structural and mechanical applications.

Is 1020 steel round bar suitable for high-stress applications?

For moderate-stress applications, 1020 steel round bar is suitable. However, for high-stress or high-load situations, higher-carbon or alloy steels may be more appropriate due to their increased hardness and strength.