3 Costly Misconceptions About Billet Steel Definition

Table of Contents

Introduction

In the steel industry, precise terminology is crucial for ensuring quality, efficiency, and safety. One term that often causes confusion is billet steel. Misunderstanding its definition can lead to costly mistakes in material selection, processing, and application. This article aims to clarify the true nature of billet steel, debunk common misconceptions, and provide insights into its proper use.

What Is Billet Steel? A Detailed Explanation

Definition and Characteristics

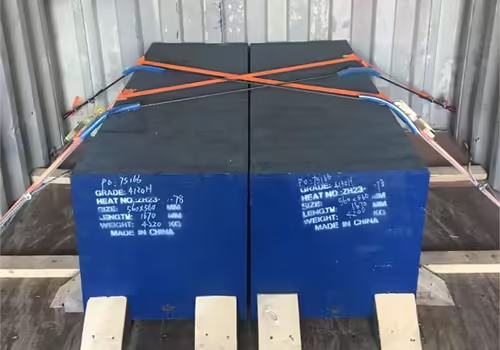

Billet steel is a semi-finished steel product characterized by its relatively small and uniform cross-sectional shape, typically square or rectangular, with dimensions generally up to 150 mm on each side. Unlike blooms or slabs, billets have a smaller cross-section, making them ideal intermediates for producing a wide range of finished steel products. These include steel bars, rods, wire, tubes, and various structural components used across multiple industries such as construction, automotive, and manufacturing.

The billet steel definition emphasizes not only its shape and size but also its role in the steel production chain. Billets are valued for their uniformity in chemical composition and mechanical properties, which are critical for achieving consistent quality in downstream products. Their relatively small size also facilitates easier handling and more efficient further processing compared to larger steel forms.

Production Methods

Billet steel is primarily produced through two main manufacturing methods: continuous casting and hot rolling. Both methods are designed to ensure the billets possess consistent mechanical and physical properties suitable for subsequent shaping and fabrication.

- Continuous Casting: This modern and widely used process involves pouring molten steel into a water-cooled mold, where it solidifies into the desired billet shape. Continuous casting offers excellent control over the billet’s dimensions and internal quality, minimizing defects such as segregation or porosity. This process also allows for high production rates and improved energy efficiency compared to traditional methods.

- Hot Rolling: In this method, larger steel pieces such as blooms or slabs are heated to elevated temperatures and then passed through a series of rollers that reduce their cross-sectional size to the billet dimensions. Hot rolling helps refine the steel’s grain structure, improving mechanical properties like strength and toughness. It also removes surface defects, resulting in billets that are ready for further processing steps.

Both methods aim to produce billets with consistent properties suitable for further processing.

Additional Characteristics and Quality Control

Billet steel is generally produced to meet strict standards and specifications set by organizations such as ASTM and EN, which dictate the chemical composition, mechanical properties, and dimensional tolerances. These standards are integral to the billet steel definition, ensuring that billets are consistent and reliable inputs for manufacturing processes.

Key characteristics of billet steel, as outlined in the billet steel definition, include high tensile strength, good ductility, and uniform grain structure. Quality control measures during production—such as ultrasonic testing, dimensional inspections, and chemical analysis—are vital to ensure that the billets conform to the established billet steel definition standards. The overall quality of billets directly impacts the performance and safety of the final steel products made from them, making adherence to the billet steel definition crucial.

Applications of Billet Steel

Thanks to its intermediate size and excellent properties defined by the billet steel definition, billet steel serves as the foundational material for many products. It is commonly transformed into:

- Steel bars and rods for construction and machinery

- Wire rods for electrical cables and springs

- Structural components used in bridges, buildings, and automotive parts

- Forged parts requiring high strength and precision

The versatility of billets underlines the importance of fully understanding the billet steel definition to optimize their use and ensure that end products meet rigorous industry requirements. Proper knowledge of the billet steel definition allows manufacturers to select the correct billet type and grade, improving product quality and reducing material waste.

Misconception 1: Billet Steel Is Just a Random Steel Form

The Reality Behind Billet Steel Definition

Billet steel is not a generic or random steel form; it is a precisely defined intermediate steel product used widely in metalworking and manufacturing industries. Its definition is governed by well-established standards such as ASTM A29 (Standard Specification for Steel Billets, Blooms, and Slabs for Structural Applications) and EN 10079 (European Standard defining hot rolled steel billets).

- Chemical Composition: These standards specify limits on carbon, manganese, sulfur, phosphorus, and other alloying elements.

- Mechanical Properties: Billets must meet minimum tensile strength, yield strength, and elongation percentages.

- Dimensional Tolerances: Typically, billets have a cross-sectional size less than 150 mm x 150 mm, usually square or round, which differentiates them from blooms and slabs.

For example, ASTM A29 designates grades such as 1020 (mild carbon steel), 1045 (medium carbon steel), and 4140 (chromium-molybdenum alloy steel), each with distinct mechanical and metallurgical properties tailored for specific end-use scenarios like forging, machining, or construction.

Financial Impact of This Misconception

Misunderstanding billet steel as a random or generic material can cause several costly problems:

- Incorrect Material Selection: Choosing a billet with improper grade or chemical composition can compromise the performance of the final product, leading to early failure or inability to meet design specifications.

- Increased Processing Costs: Using billets not suited for the application may require additional heat treatment, machining, or finishing processes, driving up production time and expenses.

- Quality Control Issues: Products manufactured from inappropriate billets may face defects, dimensional inaccuracies, or mechanical failures, increasing scrap rates and rework costs.

Key Parameters to Understand

| Parameter | Typical Range or Value | Impact on Quality/Usage |

|---|---|---|

| Cross-section size | ≤ 150 mm (square or round) | Differentiates billet from bloom or slab |

| Carbon content | 0.15% – 0.50% (varies by grade) | Influences hardness and tensile strength |

| Tensile strength | 400 – 900 MPa (depending on grade) | Determines load-bearing capacity |

| Dimensional tolerance | ±1 to 3 mm | Affects machining precision and final product fit |

Misconception 2: All Billet Steel Has the Same Chemical Composition

Chemical Composition Variability

Billet steel is not uniform; it varies significantly depending on the intended application and required mechanical properties. The three main types include:

- Carbon Steel Billets: Primarily composed of iron and carbon, with small quantities of manganese, sulfur, and phosphorus. Carbon content varies, typically from 0.15% to 0.50%, controlling strength and ductility.

- Alloy Steel Billets: These contain added elements like chromium, nickel, molybdenum, and vanadium, which improve hardness, toughness, wear resistance, and heat resistance. For example, 4140 alloy steel billets have chromium and molybdenum to increase fatigue strength.

- Stainless Steel Billets: Contain high levels of chromium (usually over 10.5%) and often nickel, providing excellent corrosion and oxidation resistance, suitable for harsh environments.

Why Chemical Composition Matters

The chemical makeup directly influences:

- Mechanical Properties: Higher carbon increases hardness but reduces ductility; alloying elements improve tensile strength and fatigue resistance.

- Corrosion Resistance: Stainless steel billets excel here due to chromium’s passivating layer.

- Machinability and Weldability: Some compositions allow easier machining or welding, reducing manufacturing complexity.

Typical Chemical Composition of Common Billet Grades

| Grade | C (%) | Mn (%) | Cr (%) | Ni (%) | Mo (%) | Application |

|---|---|---|---|---|---|---|

| 1020 | 0.18-0.23 | 0.30-0.60 | – | – | – | General purpose, low carbon steel |

| 1045 | 0.43-0.50 | 0.60-0.90 | – | – | – | Medium carbon, forgings, machinery parts |

| 4140 | 0.38-0.43 | 0.75-1.00 | 0.80-1.10 | 0.15-0.25 | 0.15-0.25 | High strength alloy steel, automotive |

ensures that the final product meets performance requirements and reduces the risk of failure.

Misconception 3: Billet Steel Requires No Further Processing

Importance of Secondary Processing

Billets are semi-finished products, not end-use materials. They require secondary processes to transform them into usable forms such as bars, rods, wires, or forged components.

- Hot Rolling: The billet is reheated above its recrystallization temperature (typically 1100°C to 1250°C) and rolled to reduce size and shape it into bars or rods.

- Cold Rolling: Performed at or near room temperature, improves surface finish, dimensional accuracy, and mechanical strength by strain hardening.

- Forging: Applies compressive forces to refine grain structure, enhancing toughness and fatigue life.

Risks of Skipping Processing

Failure to apply proper secondary processes may cause:

- Inconsistent Mechanical Properties: Without hot or cold rolling, billets may retain internal stresses and heterogeneity.

- Surface Defects: As-cast billets may have scale, porosity, or cracks that affect product integrity.

- Poor Durability: Lack of grain refinement or heat treatment reduces fatigue resistance and lifespan.

Key Processing Parameters

| Process | Temperature Range | Effect on Material | Typical Uses |

|---|---|---|---|

| Hot Rolling | 1100°C – 1250°C | Grain refinement, dimensional shaping | Bars, rods, structural shapes |

| Cold Rolling | Room temperature | Improves surface finish and strength | Precision bars, wires |

| Forging | 850°C – 1200°C | Enhances mechanical properties via grain structure | Automotive parts, tools |

Billet Steel Definition Comparison Table

| Steel Form | Dimensions (mm) | Common Uses | Chemical Composition Variability | Production Process |

|---|---|---|---|---|

| Billet Steel | Up to 150 | Bars, rods, wire production | High | Continuous casting, hot rolling |

| Bloom | >150 to 250 | Structural shapes, heavy sections | Moderate | Similar to billet, larger size |

| Slab | >250 | Plates, sheets, coils | Moderate to high | Continuous casting, hot rolling |

Understanding these distinctions helps in selecting the appropriate material for specific applications.

Conclusion

A precise and thorough understanding of billet steel definition is critical to avoiding costly mistakes in steel production and application. Knowing the billet steel definition, recognizing its chemical variability, and understanding its role as an intermediate product ensures better material selection, manufacturing efficiency, and product reliability.

Industries relying on steel must emphasize accurate terminology and quality control starting with the billet steel definition stage onward. This knowledge of billet steel definition empowers companies to optimize operations, reduce waste, and deliver higher-quality products to market.

FAQ

What distinguishes billet steel from other steel forms?

The billet steel definition clarifies that billet steel is smaller in size (under 150 mm cross-section), usually square or round, and is used as an intermediate product for rods, bars, and wire.

Can billet steel be used directly in manufacturing?

Typically, billet steel requires further processing like forging or rolling before it is suitable for most applications.

How does chemical composition affect billet steel?

Understanding the billet steel definition involves recognizing that different chemical compositions tailor billets to various mechanical and physical requirements, affecting strength, corrosion resistance, and workability.

Why is it important to understand billet steel definition accurately?

Accurate knowledge of the billet steel definition prevents poor material choices, reduces production issues, and lowers operational costs.

What are the standard sizes for billet steel?

The billet steel definition usually includes billets having cross-sectional sizes below 150 mm, although specifications can vary by industry and application.