3 Critical Factors When Comparing Steel Plate for Sale

Table of Contents

Introduction

In today’s competitive industrial marketplace, selecting the right steel plate for sale can mean the difference between project success and costly failures. Whether you’re sourcing materials for construction, heavy machinery, shipbuilding, or infrastructure projects, understanding how to properly evaluate steel plates is essential for engineers, procurement specialists, and fabricators alike.

The global steel plate market continues to grow, projected to reach $XX billion by 2025 according to recent industry reports. With such expansion comes both opportunity and risk – while more suppliers enter the market offering steel plate for sale, quality standards vary dramatically between manufacturers. This makes informed purchasing decisions more crucial than ever.

After consulting with metallurgical experts and analyzing hundreds of procurement cases, we’ve identified the three most critical factors that separate high-performing steel plates from substandard products:

- Material Grade & Chemical Composition

- Surface Characteristics & Dimensional Precision

- Supplier Qualifications & Quality Assurance

This comprehensive guide will explore each factor in depth, providing actionable insights to help you navigate the complex steel plate marketplace with confidence. We’ll examine industry testing standards, share expert recommendations, and reveal common pitfalls to avoid when comparing steel plate for sale.

NO 1. Material Grade & Chemical Composition

Understanding Steel Plate Metallurgy

When evaluating steel plate for sale, the metallurgical composition forms the foundation of performance. While novice buyers focus on basic dimensions, industry professionals prioritize alloy composition which directly determines:

- Tensile strength for structural integrity

- Yield strength for load-bearing capacity

- Impact resistance for toughness in steel plate applications

- Weldability for fabrication ease

- Corrosion resistance for longevity

- Fatigue life for cyclic loading performance

Comprehensive Steel Plate Grade Comparison

The following expanded table provides detailed specifications for common structural and alloy steel plate grades:

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation % | Typical Applications | Key Alloying Elements |

|---|---|---|---|---|---|

| ASTM A36 | 250 | 400-550 | 23 | General construction, bridges | Carbon (0.26% max) |

| ASTM A572 Gr. 50 | 345 | 450 | 21 | Heavy equipment, truck frames | Columbium, Vanadium |

| ASTM A514 | 690 | 760-895 | 18 | Mining equipment, military | Nickel, Chromium, Molybdenum |

| AR400 | 1000 | 1200 | 12 | Wear plates, dump liners | High Carbon (0.30%) |

| 304 Stainless | 205 | 515 | 40 | Food processing, marine | 18% Cr, 8% Ni |

Advanced Material Selection Considerations

Beyond basic specifications, consider these critical factors when purchasing steel plate for sale:

- Heat Treatment History:

- Confirm whether the steel plate was normalized, quenched & tempered, or annealed

- Improper heat treatment can reduce strength by 15-20% in structural steel plates

- Trace Element Content:

- Sulfur/phosphorus content below 0.025% improves weldability in steel plate for sale

- Residual copper/nickel affects low-temperature toughness

- Through-Thickness Properties:

- Essential for steel plate experiencing z-direction stresses (e.g., welded connections)

- Requires specialized testing per ASTM A770 for critical applications

- Impact Test Requirements:

- Charpy V-notch testing at service temperatures (e.g., -40°F for Arctic applications)

- Minimum 27J energy absorption typically required for structural steel plate

Industry Standards Compliance

Always verify that the steel plate for sale meets relevant standards:

- ASTM (American Society for Testing and Materials)

- EN (European Norms)

- JIS (Japanese Industrial Standards)

- ISO (International Organization for Standardization)

Reputable suppliers should provide certified mill test reports documenting compliance with these specifications.

NO 2. Surface Characteristics & Dimensional Precision

The Science of Steel Plate Surfaces

When purchasing steel plate for sale, surface quality is a critical factor that impacts performance far beyond aesthetics. The surface characteristics of steel plate directly determine:

- Coating Adhesion: Roughness affects paint and protective coating bonding

- Corrosion Resistance: Surface defects accelerate rust formation

- Fatigue Performance: Micro-cracks reduce service life under cyclic loading

- Weld Quality: Surface contamination leads to weld defects

- Machining Characteristics: Surface finish impacts tool wear and precision

Advanced Surface Finish Analysis

Beyond basic hot-rolled vs. cold-rolled distinctions, consider these specialized surface treatments:

| Surface Treatment | Process Description | Surface Roughness (Ra μm) | Advantages | Limitations |

|---|---|---|---|---|

| Shot Blasting | High-velocity steel shot impact | 3.0-6.0 | Excellent paint adhesion, removes mill scale | Additional cost |

| Pickling | Acid bath removal of oxides | 1.0-2.5 | Clean surface for plating | Environmental concerns |

| Skin Pass Rolling | Light cold reduction | 0.5-1.5 | Improved flatness, surface finish | Limited thickness reduction |

| Laser Cleaning | Precision oxide removal | 0.8-1.2 | No chemical residues | High equipment cost |

Dimensional Tolerances: Beyond Basic Specifications

When comparing steel plate for sale from different suppliers, these dimensional factors significantly impact usability and cost-effectiveness:

- Thickness Variations:

- Standard ASTM A6 allows ±0.010″ variation on 0.5″ steel plate

- Precision applications may require ±0.005″ or better

- Thicker steel plate for sale (over 2″) often has wider tolerance bands

- Flatness Standards:

- Commercial flatness (typical mill production) vs. precision flatness

- Laser cutting operations require steel plate flatness within 3mm/m

- Stress-relieved steel plate maintains better flatness during processing

- Edge Conditions:

- Sheared edges (standard) vs. machined edges (precision applications)

- Burr height must be <0.005″ for critical welding of steel plate

- Flame-cut edges may require additional machining for some uses

- Length/Width Tolerances:

- Standard mill tolerances typically ±1/8″ on width, ±1/4″ on length

- Precision-cut steel plate for sale can hold ±0.030″ for CNC applications

- Accumulated error becomes significant in large plate stacks

Non-Destructive Testing (NDT) for Surface Defects

Reputable suppliers should perform:

- Ultrasonic testing for internal flaws

- Magnetic particle inspection for surface cracks

- Eddy current testing for sub-surface defects

Special Considerations for Steel Plate for Sale

1. Surface Protection Options

- Temporary protectants (oils, VCI paper) for corrosion prevention

- Permanent coatings (galvanizing, epoxy) for specific environments

2. Custom Processing

- Beveling edges for welding preparation

- CNC drilling/pre-cutting to reduce fabrication time

- Stress relieving to minimize distortion

3. Certification Requirements

- Mill test certificates for each steel plate lot

- Third-party inspection reports when required

- Material traceability documentation

NO 3. Supplier Qualifications & Quality Assurance

Comprehensive Supplier Evaluation Framework

When sourcing steel plate for sale, rigorously assess suppliers against these criteria to ensure premium quality and reliability:

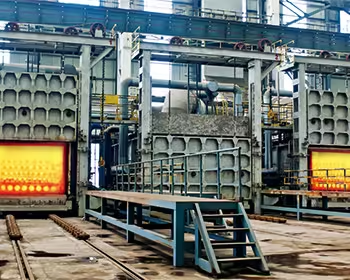

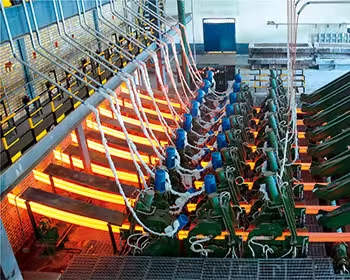

Manufacturing Capabilities

- Mill type (integrated vs. mini-mill) for steel plate production

- Rolling equipment capacity for steel plate thickness/width tolerances

- Heat treatment facilities (normalizing, quenching & tempering)

- Accredited testing laboratories for steel plate quality verification

Quality Systems

- ISO 9001-certified steel plate for sale suppliers

- Six Sigma and statistical process control (SPC) for defect reduction

- Full traceability from raw materials to finished steel plates

Technical Support

- Metallurgical expertise for steel plate grade selection

- Application engineering for fabrication (cutting, bending, welding)

- Failure analysis and welding consultation services

Supply Chain Reliability

- Inventory management for steel plate for sale availability

- Consistent lead times and logistics for global steel plate procurement

- Emergency response for urgent steel plate orders

Decoding Mill Test Reports

A valid mill test report for steel plate for sale must include:

- Chemical Analysis:

- Ladle vs. product analysis (ASTM A751 compliance)

- Spectrographic verification of alloying elements

- Mechanical Properties:

- Tensile strength, yield strength, and elongation (per ASTM A6/A20)

- Impact test results (for grades like A516 or A572)

- Heat Treatment Details:

- Temperature logs for normalization/quenching

- Quenching medium (water, oil) and tempering parameters

- NDT Results:

- Ultrasonic testing (UT) maps for internal flaws

- Surface inspection reports (VT, MT, PT)

Global Steel Plate Supply Chain Considerations

Navigate the steel plate for sale market with these insights:

- Regional production differences: Compare EU (EN standards), US (ASTM), and Asia (JIS/GB).

- Trade compliance: Anti-dumping duties (e.g., HRC from Vietnam) and INCOTERMS.

- Sustainability: Certified steel plates for sale (ISO 14001, Responsible Steel™).

- Logistics: Currency fluctuations and shipping costs impacting steel plate pricing.

Conclusion

Selecting the optimal steel plate for sale requires moving beyond basic price comparisons to evaluate three fundamental dimensions:

- Metallurgical Integrity – Matching alloy composition and mechanical properties to application requirements through rigorous grade selection and verification.

- Precision Manufacturing – Ensuring surface characteristics and dimensional tolerances meet the demands of fabrication processes and final use conditions.

- Supply Chain Assurance – Partnering with technically competent suppliers who maintain robust quality systems and provide complete material traceability.

By applying this comprehensive evaluation framework, engineering and procurement professionals can significantly reduce project risks while optimizing total cost of ownership. Remember that the true cost of steel plates includes not just the purchase price, but also:

- Fabrication efficiency

- Maintenance requirements

- Service life expectancy

- Failure consequences

Investing time in proper steel plate for sale evaluation ultimately pays dividends through improved project outcomes and long-term operational reliability.

FAQ

How does carbon content affect steel plate performance?

Carbon content directly influences strength and hardness but reduces weldability and toughness. Low-carbon steels (<0.25%) offer better formability, while high-carbon steels (>0.55%) provide greater wear resistance.

What’s the difference between AR400 and AR500 steel plates?

AR400 has a Brinell hardness of 400, while AR500 reaches 500. AR500 offers superior abrasion resistance but is more challenging to form and weld. Choose based on specific wear conditions.

How should I store steel plates before use?

Store horizontally on leveled, padded supports in a dry environment. Keep plates separated using dunnage to prevent moisture trapping. Outdoor storage requires proper covering and ventilation.

What certifications should I look for in structural steel plates?

Certification requirements vary by application: CE marking (EN 10025) is mandatory for European construction projects, while AISC certification ensures compliance with American building codes. Marine applications require ABS or DNV approval, and pressure vessels need ASME stamps. For corrosive environments, verify NACE MR0175/ISO 15156 compliance. Critical infrastructure projects often demand additional third-party inspection certificates. Always confirm certifications match the project specifications and local building codes.

How can I verify the authenticity of imported steel plates?

Authenticity verification requires cross-checking multiple documents: Original mill test certificates should bear embossed seals with heat numbers matching the material markings. Third-party inspection reports (from SGS, BV, or similar) must reference the same batch numbers. Commercial invoices should include correct harmonized system codes (HS codes) for steel products. Physically verify permanent markings (stamping or engraving) on plate edges showing grade, size, and manufacturer identification. For high-value orders, consider spectrometer testing to verify composition matches certificates.