42CrMo4 Round Bar: Properties and Uses

Table of Contents

Introduction

The 42CrMo4 round bar is a high-quality alloy steel that is widely used in the manufacturing of various industrial components. Known for its excellent strength, hardness, and wear resistance, 42CrMo4 is commonly utilized in applications requiring high tensile strength and durability. As a result, this material is frequently found in automotive, engineering, and heavy machinery industries.

In this article, we will explore the key properties, benefits, and uses of the 42CrMo4 round bar. We will also provide insights into how it compares to other steel grades and how to choose the right 42CrMo4 round bar for specific applications.

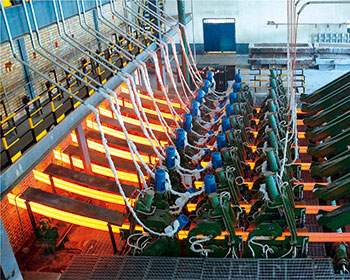

Henan Jiyuan Iron and Steel (Group) Co., Ltd. was founded in 1958. It has rich experience in production and research and development. It provides you with one-stop steel services and welcomes consultations from customers around the world.

What is 42CrMo4 Round Bar?

42CrMo4 is a chromium-molybdenum alloy steel that offers enhanced mechanical properties compared to standard carbon steels. It contains chromium (Cr) and molybdenum (Mo), two elements that significantly improve the steel’s hardenability, strength, and wear resistance. The 42CrMo4 round bar is primarily available in the form of rods or bars that are circular in shape, making it ideal for machining into precise parts such as shafts, gears, and other critical components.

Key Composition of 42CrMo4 Round Bar:

- Carbon (C): 0.38% – 0.45%

- Chromium (Cr): 0.90% – 1.20%

- Molybdenum (Mo): 0.15% – 0.25%

- Manganese (Mn): 0.60% – 0.90%

- Silicon (Si): 0.20% – 0.35%

- Phosphorus (P): ≤ 0.035%

- Sulfur (S): ≤ 0.035%

Properties of 42CrMo4 Round Bar

The unique combination of chromium and molybdenum in 42CrMo4 round bars imparts several outstanding mechanical and chemical properties. Here are some of the most notable characteristics:

High Strength and Toughness

One of the primary benefits of 42CrMo4 round bars is their high tensile strength, which makes them ideal for applications that require materials to withstand significant stress and pressure. This steel also has excellent toughness, making it resistant to fracture and wear even under extreme conditions.

Excellent Hardenability

Due to the presence of chromium and molybdenum, 42CrMo4 round bars exhibit excellent hardenability. This means that the steel can be heat-treated to achieve superior hardness levels, which is essential for parts exposed to wear and tear, such as gears and shafts.

Good Corrosion Resistance

While not entirely corrosion-proof, 42CrMo4 steel has good resistance to rust and corrosion, particularly when compared to standard carbon steels. This is one of the reasons why it is used in outdoor applications where exposure to harsh environments is common.

Heat Resistance

The addition of chromium and molybdenum gives 42CrMo4 round bars excellent heat resistance, allowing them to maintain their structural integrity and mechanical properties even at high temperatures. This makes them suitable for use in automotive engines and other machinery that operates under elevated temperatures.

Applications of 42CrMo4 Round Bar

The versatile properties of 42CrMo4 round bars make them suitable for a wide range of applications. Below are some of the most common uses of this material:

Automotive Industry

42CrMo4 round bars are widely used in the production of components for the automotive industry. They are used to manufacture engine parts, shafts, gears, and crankshafts, where high strength and resistance to wear are essential.

Engineering and Construction

Due to its high tensile strength, 42CrMo4 round bars are also used in the construction of machinery, heavy-duty equipment, and structural components that require high load-bearing capacity.

Tool Manufacturing

42CrMo4 round bars are frequently used in the production of tools and dies, particularly in industries that require precision parts. Their excellent hardness and wear resistance make them ideal for creating durable cutting tools and molds.

Aerospace Industry

The aerospace sector uses 42CrMo4 round bars in various components that require high strength and reliability. This includes parts such as landing gears, shafts, and turbine blades, where the material must endure extreme stress and temperature fluctuations.

Comparing 42CrMo4 Round Bar with Other Steel Grades

When choosing a material for your project, it is important to compare 42CrMo4 round bars with other steel grades to ensure you select the most appropriate option. Below is a table comparing 42CrMo4 with other common alloy steels:

| Property | 42CrMo4 | AISI 4140 | AISI 4340 |

|---|---|---|---|

| Tensile Strength | 850 – 1000 MPa | 655 – 850 MPa | 745 – 1020 MPa |

| Yield Strength | 650 – 900 MPa | 415 – 655 MPa | 655 – 890 MPa |

| Hardness | 28 – 34 HRC | 25 – 30 HRC | 28 – 34 HRC |

| Carbon Content | 0.38% – 0.45% | 0.38% – 0.43% | 0.38% – 0.43% |

| Chromium Content | 0.90% – 1.20% | 0.80% – 1.10% | 0.70% – 0.90% |

| Molybdenum Content | 0.15% – 0.25% | 0.15% – 0.25% | 0.20% – 0.30% |

| Typical Uses | Automotive, engineering | Heavy machinery, automotive | Aerospace, military, engineering |

How to Choose the Right 42CrMo4 Round Bar

When selecting the best 42CrMo4 round bar for your application, there are several factors to consider:

Application Requirements

Evaluate the mechanical and physical demands of your application. Choose a 42CrMo4 round bar with the appropriate tensile strength, hardness, and corrosion resistance based on the environment and load requirements.

Heat Treatment

42CrMo4 can be heat-treated to enhance its properties. Determine whether your application

requires a specific heat treatment process to improve hardness, strength, or other characteristics. Some applications may require quenching and tempering to achieve optimal performance.

Dimensions and Tolerances

Ensure that the 42CrMo4 round bar is available in the correct dimensions for your project. Check for the necessary length, diameter, and tolerance levels to meet your design specifications.

Supplier Reliability

Choosing a reputable supplier for your 42CrMo4 round bar is crucial to ensure consistent material quality and compliance with international standards. Verify the supplier’s certifications, such as ISO 9001, to guarantee that the material meets industry-specific requirements.

Conclusion

The 42CrMo4 round bar is an incredibly versatile and durable material that offers numerous benefits across various industries, including automotive, aerospace, and engineering. Its exceptional strength, hardness, and wear resistance make it an excellent choice for high-demand applications where durability is critical.

By understanding the properties, uses, and comparison with other steel grades, businesses can make an informed decision when selecting 42CrMo4 steel round bars for their projects. The material’s adaptability, coupled with its ability to withstand harsh conditions, makes it a preferred choice for manufacturers worldwide.

FAQ

What is 42CrMo4 steel round bar?

42CrMo4 steel round bar is an alloy steel made from chromium and molybdenum, providing enhanced mechanical properties like high tensile strength, hardness, and wear resistance. It is often used in automotive, engineering, and tool manufacturing industries.

What are the key benefits of using 42CrMo4 steel round bars?

The key benefits of 42CrMo4 steel round bars include their excellent tensile strength, wear resistance, high hardenability, and good corrosion resistance, making them ideal for demanding applications in various industries.

How is 42CrMo4 steel round bar used in the automotive industry?

In the automotive industry, 42CrMo4 steel round bars are commonly used to produce components like shafts, gears, and crankshafts, where high strength and durability are essential.

Can 42CrMo4 steel round bars be heat-treated?

Yes, 42CrMo4 steel round bars can be heat-treated to enhance their properties. Common heat treatments include quenching and tempering, which improve hardness and toughness.

How does 42CrMo4 round bar compare to AISI 4140 and AISI 4340?

42CrMo4 steel round bars have comparable tensile strength and hardness to AISI 4140 and AISI 4340 but are often more affordable. AISI 4340 offers higher strength and is typically used in aerospace and military applications.