42CrMo4 Steel: Properties, Uses, and Benefits Explained

Introduction

42CrMo4 steel, also known as 42CrMo or EN19, is a high-quality alloy steel widely used in various industries due to its exceptional strength, toughness, and wear resistance. This versatile material is particularly renowned for its performance in demanding applications, making it a popular choice for components subjected to high stress and severe conditions. In this blog post, we will explore the properties, applications, and benefits of 42CrMo4 steel in detail, offering insights into why it is a preferred material in engineering and manufacturing.

What is 42CrMo4 Steel?

42CrMo4 steel is an alloy steel that belongs to the chromium-molybdenum family. The designation “42CrMo4” indicates the chemical composition of the steel: approximately 0.42% carbon (C), 0.9-1.2% chromium (Cr), and 0.15-0.3% molybdenum (Mo). This unique composition endows 42CrMo4 with several important characteristics, including enhanced hardenability, strength, and resistance to wear.

Key Characteristics of 42CrMo4 Steel

High Strength: 42CrMo4 steel exhibits excellent tensile and yield strength, making it suitable for high-load applications.

Good Toughness: The steel maintains good impact resistance, which is crucial for components subjected to sudden shocks and stresses.

Wear Resistance: The alloying elements contribute to a higher wear resistance, making 42CrMo4 an excellent choice for parts that experience friction and abrasion.

Heat Treatable: This steel can be heat-treated to enhance its mechanical properties further, allowing for tailored performance based on specific requirements.

Versatile: 42CrMo4 is suitable for a wide range of applications across various industries, including automotive, aerospace, and construction.

Properties of 42CrMo4 Steel

Understanding the properties of 42CrMo4 steel is crucial for its effective application. Below is a table summarizing its key mechanical and physical properties:

| Property | Value |

|---|---|

| Chemical Composition | C: 0.42%, Cr: 0.9-1.2%, Mo: 0.15-0.3% |

| Density | 7.85 g/cm³ |

| Tensile Strength | 1000-1200 MPa |

| Yield Strength | 850-1000 MPa |

| Elongation | 12-20% |

| Hardness (HB) | 235-300 |

| Thermal Conductivity | 43 W/m·K |

| Specific Heat Capacity | 0.46 kJ/kg·K |

Applications of 42CrMo4 Steel

42CrMo4 steel is widely used in various industries due to its excellent properties. Below are some of the key applications of 42CrMo4 steel:

Automotive Industry

In the automotive sector, 42CrMo4 steel is used for manufacturing high-stress components such as gears, axles, and crankshafts. Its strength and toughness make it suitable for critical parts that need to withstand heavy loads and dynamic forces.

Aerospace Industry

The aerospace industry requires materials that can endure extreme conditions, making 42CrMo4 steel a suitable choice for components such as landing gear and engine mounts. Its lightweight yet strong nature is ideal for improving overall aircraft performance.

Construction Industry

In construction, 42CrMo4 steel is used in the fabrication of structural components, such as beams and supports. Its excellent strength-to-weight ratio ensures that structures can bear significant loads while maintaining integrity.

Oil and Gas Industry

42CrMo4 steel is utilized in the oil and gas sector for manufacturing drill pipes, valves, and fittings. The steel’s resistance to wear and corrosion is vital in harsh environments encountered in drilling operations.

Heavy Machinery

Heavy machinery components, such as excavator arms and hydraulic cylinders, benefit from the durability and strength of 42CrMo4 steel. Its ability to handle heavy loads and resist wear makes it a preferred material for these applications.

Benefits of Using 42CrMo4 Steel

The advantages of 42CrMo4 steel make it a preferred choice for various applications. Here are some of the key benefits:

Enhanced Performance

The high strength and toughness of 42CrMo4 steel ensure that components made from this material can perform effectively under demanding conditions, leading to longer service life and reduced maintenance costs.

Heat Treatment Flexibility

42CrMo4 steel can be heat-treated to achieve specific hardness and strength levels. This flexibility allows manufacturers to tailor the material properties to meet the requirements of different applications.

Cost-Effective Solution

While 42CrMo4 steel may be more expensive than some standard steels, its durability and performance benefits often result in lower overall costs in the long run. Reduced failure rates and maintenance requirements translate to significant savings.

Wide Availability

42CrMo4 steel is widely available and can be sourced from various suppliers, making it easy for manufacturers to procure the material when needed.

Versatile Applications

The versatility of 42CrMo4 steel means it can be used across multiple industries, allowing manufacturers to standardize materials for different applications, simplifying inventory management.

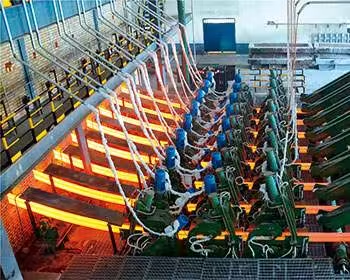

Heat Treatment of 42CrMo4 Steel

Heat treatment plays a crucial role in enhancing the properties of 42CrMo4 steel. Common heat treatment processes include:

Annealing

Annealing involves heating the steel to a specific temperature followed by slow cooling. This process improves ductility and reduces hardness, making it easier to machine.

Quenching and Tempering

Quenching involves heating the steel to a high temperature and then rapidly cooling it in water or oil. This process increases hardness but can make the steel brittle. Tempering follows quenching, where the steel is reheated to a lower temperature to achieve a balance between hardness and toughness.

Normalizing

Normalizing involves heating the steel to a temperature above its critical point and then air-cooling. This process refines the grain structure, improving the overall mechanical properties of the steel.

Conclusion

42CrMo4 steel is an exceptional material that combines strength, toughness, and versatility, making it a popular choice for various demanding applications across industries. Its unique properties, such as high strength and wear resistance, along with its ability to undergo heat treatment, allow for tailored performance based on specific requirements. Whether in the automotive, aerospace, or construction sector, 42CrMo4 steel continues to prove its worth as a reliable material for high-stress applications.

As industries evolve and the demand for high-performance materials increases, 42CrMo4 steel is likely to remain at the forefront of engineering solutions, delivering the durability and reliability required for modern applications.

FAQ

What is the main composition of 42CrMo4 steel?

42CrMo4 steel primarily contains approximately 0.42% carbon, 0.9-1.2% chromium, and 0.15-0.3% molybdenum, contributing to its high strength and toughness.

How does heat treatment affect 42CrMo4 steel?

Heat treatment processes such as annealing, quenching, and tempering can significantly alter the mechanical properties of 42CrMo4 steel, enhancing its strength, toughness, and machinability.

What industries commonly use 42CrMo4 steel?

42CrMo4 steel is widely used in the automotive, aerospace, construction, oil and gas, and heavy machinery industries due to its exceptional performance characteristics.

Can 42CrMo4 steel be welded?

Yes, 42CrMo4 steel can be welded, but preheating and post-weld heat treatment are often recommended to minimize the risk of cracking and ensure optimal properties.

What are the main benefits of using 42CrMo4 steel?

The main benefits include enhanced performance in high-stress applications, heat treatment flexibility, cost-effectiveness, wide availability, and versatility across multiple industries.