5 Deadly Steel Square Tube Errors You Must Avoid

Table of Contents

Introduction

Steel square tubes are among the most widely used structural components in construction, manufacturing, and engineering due to their high strength-to-weight ratio, durability, and ease of fabrication. However, despite their versatility, improper selection, handling, or installation can lead to costly failures, safety hazards, and project delays.

Whether you’re a contractor, engineer, fabricator, or DIY enthusiast, understanding the common pitfalls associated with steel square tubes is crucial. In this comprehensive guide, we will explore five critical mistakes that can compromise the performance and longevity of steel square tubes—and how to avoid them.

By the end of this article, you’ll have a deeper understanding of:

- How to select the right steel square tube grade for your project

- Best practices for corrosion prevention

- Proper cutting and welding techniques

- Accurate load-bearing calculations

- Safe storage and handling methods

Let’s dive in and ensure your next project avoids these costly errors.

NO 1. Choosing the Wrong Steel Square Tube Grade

Why Material Selection Matters

Not all steel square tubes are the same. Different grades offer varying levels of strength, corrosion resistance, and weldability. Selecting the wrong type can lead to premature failure, excessive maintenance, or even structural collapse.

Common Steel Square Tube Grades & Their Applications

| Grade | Key Properties | Best Use Cases |

|---|---|---|

| ASTM A500 | High strength, structural integrity | Building frames, bridges, machinery |

| ASTM A513 | Precision-formed, smooth finish | Automotive parts, furniture |

| ASTM A36 | General-purpose, weldable | Light structures, supports |

| 304 Stainless | Corrosion-resistant, aesthetic | Marine, food processing, outdoor use |

| Galvanized | Zinc-coated for rust prevention | Outdoor structures, fencing |

Common Mistakes in Grade Selection

- Using mild steel in corrosive environments – Leads to rapid rusting.

- Choosing thin-walled tubes for heavy loads – Causes buckling or deformation.

- Opting for high-strength steel when unnecessary – Increases costs without added benefit.

How to Avoid This Error

- Consult engineering specifications before purchasing.

- Consider environmental factors (humidity, chemicals, temperature).

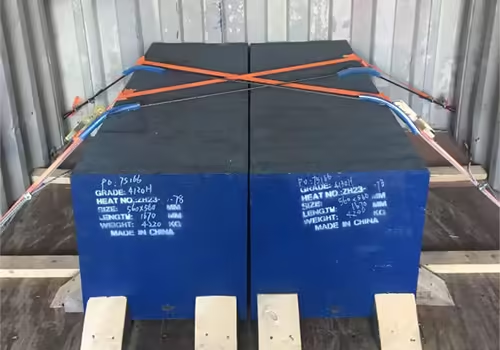

- Verify material certifications from suppliers.

NO 2. Ignoring Corrosion Protection

Why Corrosion is a Silent Killer

Steel square tubes are prone to rust, especially in humid, coastal, or industrial environments. Without proper protection, corrosion can weaken structural integrity, leading to costly repairs or replacements.

Effective Corrosion Protection Methods

| Method | Advantages | Limitations |

|---|---|---|

| Hot-Dip Galvanizing | Long-lasting, thick zinc layer | Higher initial cost |

| Powder Coating | Aesthetic, customizable colors | Less durable than galvanizing |

| Stainless Steel | Naturally corrosion-resistant | Expensive, not always necessary |

| Paint & Sealants | Cost-effective, easy to apply | Requires frequent maintenance |

Common Corrosion-Related Mistakes

- Using uncoated steel in outdoor applications – Leads to rapid rust formation.

- Skipping maintenance on painted tubes – Paint chips expose bare metal.

- Mixing dissimilar metals – Causes galvanic corrosion.

Best Practices for Corrosion Prevention

- Choose galvanized or stainless steel for harsh environments.

- Apply touch-up coatings if scratches occur.

- Avoid direct contact with other metals unless properly insulated.

NO 3. Incorrect Cutting and Welding Techniques

The Risks of Poor Fabrication

Improper cutting and welding can weaken steel square tubes, leading to cracks, warping, or structural failure.

Common Cutting & Welding Mistakes

| Error | Consequence | Solution |

|---|---|---|

| Using dull blades | Rough edges, material distortion | Use sharp, high-speed steel blades |

| Excessive heat during welding | Warping, weakened joints | Use proper heat control techniques |

| Incorrect weld penetration | Weak joints, potential failure | Follow welding procedure specs |

| Wrong filler material | Brittle or incompatible welds | Match filler to base metal grade |

Best Practices for Cutting & Welding

- Use plasma cutting or abrasive saws for clean cuts.

- Preheat thick-walled tubes to prevent cracking.

- Follow AWS (American Welding Society) guidelines for welding procedures.

NO 4. Poor Load-Bearing Calculations

Why Accurate Load Calculations Are Critical

Underestimating the load capacity of steel square tubes can lead to catastrophic failures, especially in structural applications.

Key Factors Affecting Load Capacity

- Wall thickness – Thicker walls handle heavier loads.

- Span length – Longer spans require stronger tubes.

- Material grade – High-strength steel supports more weight.

Common Load Calculation Errors

- Assuming all steel square tubes have the same strength – Different grades vary significantly.

- Ignoring dynamic loads (wind, vibration, impact) – Static calculations alone may be insufficient.

- Overlooking deflection limits – Excessive bending can cause failure over time.

How to Ensure Safe Load-Bearing Capacity

- Consult structural engineers for critical projects.

- Use industry-standard load tables (see below).

- Factor in safety margins (typically 1.5x expected load).

Steel Square Tube Load Capacity Reference (ASTM A500 Grade B)

| Size (inches) | Wall Thickness (in) | Max Load (lbs/ft, simply supported) |

|---|---|---|

| 1×1 | 0.065 | 150 |

| 2×2 | 0.120 | 500 |

| 3×3 | 0.188 | 1,200 |

| 4×4 | 0.250 | 2,500 |

NO 5. Improper Storage and Handling

Why Storage Conditions Matter

Steel square tubes can deform, rust, or get damaged if stored incorrectly. Poor handling can also lead to workplace injuries.

Common Storage & Handling Mistakes

- Stacking tubes unevenly – Causes bending or warping.

- Storing outdoors without protection – Leads to rust and degradation.

- Dragging tubes instead of lifting – Scratches and weakens the material.

Best Practices for Storage & Handling

✅ Store horizontally on flat, level racks – Prevents sagging.

✅ Use wooden or rubber padding – Avoids surface damage.

✅ Keep in a dry, covered area – Minimizes corrosion risk.

✅ Use forklifts or cranes for heavy tubes – Reduces manual handling risks.

Conclusion

Steel square tubes are indispensable in modern construction and manufacturing, but their performance depends heavily on proper selection, fabrication, and maintenance. By avoiding these five deadly errors—wrong material selection, corrosion neglect, poor cutting/welding, incorrect load calculations, and improper storage—you can ensure the longevity, safety, and cost-efficiency of your projects.

Always consult industry standards, work with certified suppliers, and involve engineers when in doubt. A small investment in proper planning today can prevent costly failures tomorrow.

FAQ

What is the strongest steel square tube grade?

ASTM A500 Grade C offers the highest strength among structural steel square tubes.

Can I use painted steel square tubes outdoors?

Yes, but they require regular maintenance. Galvanized or stainless steel is better for long-term outdoor use.

How do I prevent warping when welding steel square tubes?

Use tack welding, control heat input, and clamp the pieces securely to minimize distortion.

What is the best way to cut steel square tubes without burrs?

A bandsaw with a fine-tooth blade or plasma cutting provides clean cuts with minimal burrs.

How long do galvanized steel square tubes last?

In moderate environments, hot-dip galvanized tubes can last 50+ years without significant corrosion.