10 Reasons to Trust Steel Rods for Durability

Table of Contents

Introduction

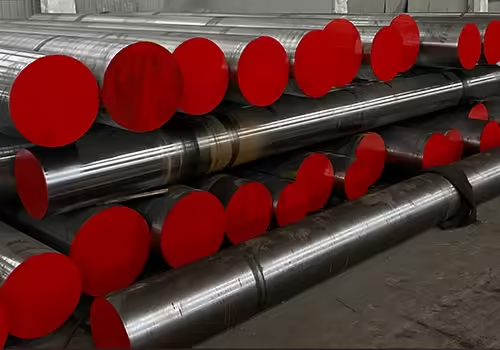

When it comes to construction and engineering projects, durability is a non-negotiable factor. Among the many materials used in these industries, steel rods have emerged as a reliable and indispensable component. Known for their strength, flexibility, and longevity, steel rods play a critical role in ensuring the stability and longevity of structures. But what makes them so durable? In this blog, we’ll explore ten compelling reasons why steel rods are trusted for their durability. Whether you’re a contractor, engineer, or DIY enthusiast, this guide will help you understand why steel rods are a top choice for durable construction.

NO 1. High Tensile Strength

One of the primary reasons for the durability of steel rods is their high tensile strength. This property allows them to withstand heavy loads and resist deformation under stress. Unlike other materials that may crack or break under pressure, steel rods maintain their integrity, making them ideal for use in foundations, bridges, and high-rise buildings.

NO 2. Resistance to Corrosion

Steel rods are often coated with protective layers to enhance their resistance to corrosion. This is particularly important in environments exposed to moisture, chemicals, or extreme weather conditions. By preventing rust and degradation, these coatings ensure that steel rods remain durable and functional for decades.

NO 3. Flexibility and Adaptability

Despite their strength, steel rods are highly flexible, allowing them to bend without breaking. This flexibility is crucial in areas prone to natural disasters like earthquakes, where structures need to absorb and dissipate energy. Steel rods provide the necessary resilience to prevent catastrophic failures.

NO 4. Fire Resistance

Steel rods are inherently fire-resistant, making them a safe choice for construction projects. Unlike materials that weaken or collapse under high temperatures, steel rods retain their structural integrity, providing additional time for evacuation and minimizing damage during fire incidents.

NO 5. Longevity and Low Maintenance

The durability of steel rods translates to a longer lifespan for structures. They require minimal maintenance compared to other materials, reducing long-term costs. This longevity makes them a cost-effective solution for projects that demand durability and reliability.

NO 6. Consistent Quality

Steel rods are manufactured under strict quality control standards, ensuring consistent performance. This uniformity means that every rod meets the same high standards, providing predictable and reliable results in construction projects.

NO 7. Eco-Friendly and Recyclable

Steel rods are not only durable but also environmentally friendly. They are 100% recyclable, reducing waste and promoting sustainability. This eco-friendly aspect makes them a preferred choice for green building projects.

NO 8. Versatility in Applications

From residential buildings to industrial complexes, steel rods are versatile enough to be used in a wide range of applications. Their adaptability to different construction needs further underscores their durability and reliability.

NO 9. Enhanced Structural Integrity

When used in reinforced concrete, steel rods significantly enhance the structural integrity of buildings. They work in tandem with concrete to create a composite material that is stronger and more durable than either material alone.

NO 10. Proven Track Record

The durability of steel rods is backed by decades of successful use in construction projects worldwide. Their proven track record in various environments and applications makes them a trusted choice for engineers and contractors.

Key Features of Steel Rods

To summarize the reasons why steel rods are trusted for durability, here’s a table highlighting their key features:

| Feature | Details |

|---|---|

| High Tensile Strength | Withstands heavy loads and resists deformation. |

| Corrosion Resistance | Protective coatings prevent rust and degradation. |

| Flexibility | Bends without breaking, ideal for earthquake-prone areas. |

| Fire Resistance | Retains structural integrity under high temperatures. |

| Longevity | Long lifespan with minimal maintenance. |

| Consistent Quality | Manufactured under strict quality control standards. |

| Eco-Friendly | 100% recyclable and sustainable. |

| Versatility | Suitable for a wide range of construction applications. |

| Structural Integrity | Enhances strength when used in reinforced concrete. |

| Proven Track Record | Decades of successful use in various projects. |

Conclusion

The durability of steel rods is unmatched, making them a cornerstone of modern construction and engineering. Their high tensile strength, resistance to corrosion, flexibility, and fire resistance are just a few of the reasons why they are trusted for projects that demand reliability and longevity. Additionally, their eco-friendly nature, versatility, and proven track record further solidify their position as a top choice for builders and engineers worldwide.

Whether you’re working on a small residential project or a large-scale industrial complex, steel rods provide the durability and performance needed to ensure the success and longevity of your structure. By understanding their unique advantages, you can make an informed decision and trust steel rods to deliver exceptional results.

FAQ

Q1: What makes steel rods more durable than other materials?

A1: Steel rods are durable due to their high tensile strength, corrosion resistance, flexibility, and fire resistance, among other factors.

Q2: How do steel rods prevent corrosion?

A2: Steel rods are often coated with protective layers, such as galvanization, to prevent rust and degradation.

Q3: Are steel rods suitable for earthquake-prone areas?

A3: Yes, their flexibility allows them to absorb and dissipate energy, making them ideal for such regions.

Q4: Can steel rods be recycled?

A4: Absolutely. Steel rods are 100% recyclable, making them an eco-friendly choice.

Q5: Why are steel rods used in reinforced concrete?

A5: Steel rods enhance the structural integrity of concrete, creating a stronger and more durable composite material.