Our Advantage

steelmaking

Rolling Steel

heat treatment

produce procedure and heat treatment services

We can supply following heat treatment services

The produce procedure and heat treatment services involve carefully controlled processes that ensure the steel are manufactured to exact specifications and then treated to enhance their mechanical properties and durability.

Smelting

Forging

Rolling

Normalizing

Annealing

Quenching and tempering

Centerless Lathe

Qlympus Ut Test

PROCESS EQUIPMENT

steelmaking

Our steelmaking system includes the following equipment:

Top and bottom combined blown converters:

LF refining furnaces:

Continuous casting machine:

1

1,300-ton metal mixer

1

120-ton dual-station KR desulfurization unit

2

120-ton top and bottom combined blown converters

2

60-ton top and bottom combined blown converters

4

120-ton LF refining furnaces

2

120-ton RH refining furnaces

3

60-ton LF refining furnaces

2

60-ton VD refining furnaces

1

Comcast alloy steel bloom (round billet) continuous casting machine

1

Special steel round billet continuous casting machine

1

Eight-strand bloom continuous casting machine

1

Seven-strand bloom continuous casting machine

1

Six-strand bloom continuous casting machine

1

Five-strand bloom continuous casting machine

1

Five-strand rectangular billet continuous casting machine

5

An annual production capacity(million tons)

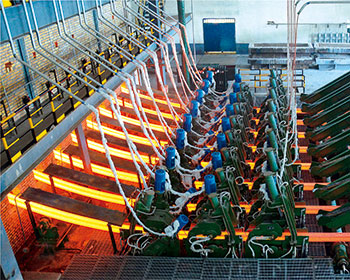

Rolling Steel

The overall process of the special steel large bar production line was

designed by Danieli Metallurgical Equipment Co., Ltd., A company based in Italy.

designed by Danieli Metallurgical Equipment Co., Ltd., A company based in Italy.

Key core equipment such as heating furnaces, breakdown mills, steel billet flame cleaning machines, continuous rolling mills, flying shears, KOCKS, combination saws, and grinding saws, and some control systems are imported from companies such as Fives Stein in France, Danieli in Italy, L-TEC in the United States, KOCKS in Germany, and Braun in Austria.

The whole line runs with a full-digital AC variable frequency drive system.

In terms of the configuration of the rolling line and the selection of rolling mills:

The fixed-length saws consist of 4 combination hot saws and Braun saws for cutting.

The production line employs the online diameter measurement technology, non-destructive testing technology, controlled rolling and cooling technology, online flame cleaning technology, and hot charging and hot delivery technology. Equipped with German KOCKS reducing and sizing rolling mills capable of achieving free size rolling ranging from ø50mm to ø160mm. It mainly produces round steel with the specification ranging from ø50mm to ø300mm, square steel with the specification ranging from 100mm×100mm to 180mm×180mm, and rolling billets with the specification ranging from 195mm×195mm to 360mm×360mm.