How to Choose the Best 4140 Steel Bar for Your Project

Introduction

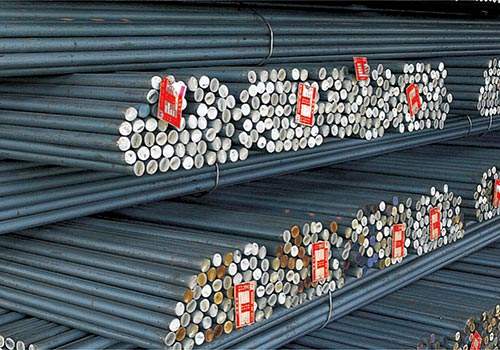

Choosing the right material is essential to the success of any engineering or industrial project. When it comes to selecting a high-performance alloy for demanding applications, the 4140 steel bar is often the top choice due to its versatility, strength, and durability. Known for its excellent mechanical properties, 4140 steel is commonly used in manufacturing, construction, and other heavy-duty applications. This guide will provide you with a comprehensive understanding of how to choose the best 4140 steel bar for your project, exploring its properties, applications, and key considerations when selecting this material.

What is 4140 Steel Bar?

4140 steel bar is a low-alloy steel that contains chromium, molybdenum, and manganese, providing a unique combination of strength, toughness, and corrosion resistance. It is classified as a medium carbon steel and is often used in applications that require high tensile strength and good impact resistance. These properties make it suitable for a wide range of industries, including automotive, aerospace, and machinery manufacturing.

Key Properties of 4140 Steel Bar

4140 steel bar offers several key mechanical properties that set it apart from other steel types:

- High tensile strength: 4140 steel has a tensile strength ranging from 655 MPa to 1100 MPa, making it ideal for structural components that require durability.

- Good impact resistance: This steel can withstand significant force without fracturing, making it perfect for heavy-duty applications.

- Heat treatability: 4140 steel bar can be heat-treated to improve its hardness, strength, and wear resistance.

- Machinability: While tougher than some other alloys, 4140 steel is still relatively easy to machine, especially after annealing or normalizing.

Applications of 4140 Steel Bar

4140 steel bars are used in a variety of applications where strength and toughness are critical:

- Automotive components: Gears, shafts, and axles benefit from 4140 steel’s strength and wear resistance.

- Aerospace parts: Its high tensile strength makes it suitable for parts that need to endure high-stress conditions.

- Heavy machinery: Pins, bolts, and couplings in construction and mining equipment often use 4140 steel.

Factors to Consider When Choosing a 4140 Steel Bar

When selecting the best 4140 steel bar for your project, several factors should be taken into account, including the specific application, required mechanical properties, and the material’s form and size. Let’s look at these considerations in more detail.

Application Requirements

The specific application for which you intend to use the 4140 steel bar will significantly influence your choice. Different applications may require varying levels of tensile strength, hardness, or impact resistance.

Strength and Durability Needs

For example, if you are manufacturing parts that will undergo heavy wear and stress, such as axles or gears, you may need a 4140 steel bar with enhanced strength and hardness achieved through heat treatment. On the other hand, for components like shafts that require good machinability, you might prefer a softer, annealed version of 4140 steel.

- Gears and axles: Require high tensile strength and wear resistance.

- Shafts: Need a balance of strength and machinability.

Heat Treatment and Hardness

One of the key features of 4140 steel is its ability to undergo various heat treatment processes. Heat treatment can significantly alter the material’s hardness, strength, and ductility, allowing you to customize the steel for specific requirements.

Common Heat Treatments for 4140 Steel Bar

- Quenching and tempering: This process involves heating the steel and then rapidly cooling it, followed by reheating to a lower temperature. It results in increased strength and hardness while maintaining some ductility.

- Annealing: Annealing softens the steel, improving machinability and making it easier to work with.

- Normalizing: Normalizing refines the grain structure, resulting in improved toughness and strength.

Sizing and Form Considerations

Another crucial factor to consider when selecting a 4140 steel bar is the size and form required for your project. 4140 steel bars come in various shapes, such as round, square, flat, or hexagonal, and the dimensions of the bar will depend on the specific needs of your application.

Choosing the Right Form of 4140 Steel Bar

The form of the steel bar you choose will depend on the type of component you are manufacturing. For instance, round bars are commonly used for shafts, while flat bars are preferred for structural components.

Typical Forms of 4140 Steel Bar

- Round bar: Best for shafts, axles, and bolts.

- Flat bar: Commonly used for brackets, braces, and base plates.

- Square bar: Suitable for machining into various custom components.

Dimension Tolerances

Ensuring that the 4140 steel bar you select meets the required dimensional tolerances is critical for proper fit and function in your project. Most suppliers provide a range of size options with varying tolerances, so make sure to specify the exact measurements needed for your application.

Comparison of 4140 Steel Bar with Other Steel Grades

To help you make an informed decision, the following table compares the properties of 4140 steel bar with other common steel grades, highlighting the key differences in strength, hardness, and applications.

| Steel Grade | Tensile Strength (MPa) | Hardness (HRC) | Best Applications |

|---|---|---|---|

| 4140 Steel Bar | 655-1100 | 28-32 | Automotive parts, heavy machinery |

| 1045 Steel Bar | 570-700 | 12-20 | General machinery, shafts |

| 4340 Steel Bar | 745-1250 | 30-40 | Aircraft parts, high-stress areas |

| A36 Steel Bar | 400-550 | 12-18 | Structural applications |

This table illustrates how 4140 steel bar compares to other grades in terms of tensile strength, hardness, and common uses, allowing you to select the best material for your project.

Conclusion

Choosing the right 4140 steel bar for your project involves understanding the specific requirements of your application, the material’s mechanical properties, and the various forms and heat treatment options available. By carefully considering factors such as strength, durability, and machinability, you can select a 4140 steel bar that meets your project’s needs and ensures optimal performance.

Whether you need a tough, heat-treated steel bar for heavy-duty machinery or a softer, annealed bar for easier machining, 4140 steel offers the versatility to meet a wide range of industrial demands.

FAQ

What is 4140 steel bar commonly used for?

4140 steel bar is commonly used in the manufacturing of automotive parts, such as gears and axles, as well as in heavy machinery, construction equipment, and aerospace components due to its strength and durability.

Can 4140 steel bar be heat treated?

Yes, 4140 steel bar is highly heat treatable. Common heat treatment methods include quenching and tempering, annealing, and normalizing, which enhance its strength, hardness, and wear resistance.

How does 4140 steel compare to 1045 steel?

4140 steel has higher tensile strength and hardness than 1045 steel, making it better suited for applications that require increased wear resistance and durability. However, 1045 steel is more economical for general-purpose applications.

Is 4140 steel bar easy to machine?

4140 steel bar is relatively easy to machine, especially when it is annealed or normalized. However, its higher strength and hardness compared to other steels can make machining more challenging if it has been heat-treated.

What forms does 4140 steel bar come in?

4140 steel bar is available in various forms, including round, flat, square, and hexagonal bars. The choice of form depends on the intended application, such as using round bars for shafts or flat bars for structural components.

How does heat treatment affect 4140 steel round bar?

Heat treatment alters the mechanical properties of 4140 steel round bar, improving its hardness, strength, and wear resistance. The most common treatments are quenching and tempering, annealing, and normalizing.

What industries commonly use 4140 steel round bar?

Industries such as automotive, aerospace, construction, and heavy machinery commonly use 4140 steel round bar due to its excellent mechanical properties, such as high tensile strength and toughness.

Can 4140 steel round bar be welded?

Yes, 4140 steel round bar can be welded, but it requires careful preheating and post-weld heat treatment to avoid cracking and ensure the weld area retains the material’s mechanical properties.

What is the hardness of 4140 steel round bar?

The hardness of 4140 steel round bar varies depending on heat treatment, but it typically ranges from 28 to 32 HRC after quenching and tempering.

How does 4340 steel compare to 4140 steel?

4340 steel has higher tensile strength and hardness than 4140 steel, making it more suitable for applications that require superior toughness and wear resistance, such as aircraft parts and high-stress components.