Choosing the Right Steel Round Bar for Your Needs

Introduction

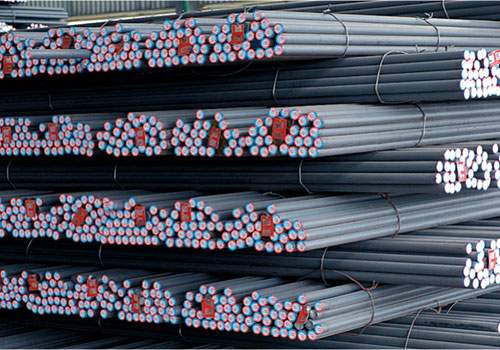

When it comes to construction, manufacturing, or engineering projects, selecting the right materials is crucial. One such material that plays a vital role is the steel round bar. Its versatility, strength, and durability make it a preferred choice in various applications. This blog will guide you through the different aspects of steel round bars, helping you choose the best option for your needs.

Understanding Steel Round Bars

Steel round bars are long cylindrical rods made from steel, characterized by their round cross-section. They come in various sizes and grades, which can affect their mechanical properties and applications.

Key Properties of Steel Round Bars

Strength: Steel round bars offer high tensile strength, making them suitable for load-bearing applications.

Durability: Steel is resistant to wear and corrosion, ensuring a long lifespan.

Versatility: These bars can be easily machined, forged, or welded, allowing for various applications.

Types of Steel Round Bars

There are several types of steel round bars, each tailored for specific uses. Below is a table summarizing some common types:

| Type | Composition | Applications |

|---|---|---|

| Carbon Steel Round Bar | Carbon, Iron | Construction, automotive components |

| Alloy Steel Round Bar | Carbon, Manganese, Chromium | High-strength applications |

| Stainless Steel Round Bar | Iron, Chromium, Nickel | Corrosion-resistant applications |

| Tool Steel Round Bar | Carbon, Tungsten, Molybdenum | Tool making, machining |

Selecting the Right Grade of Steel Round Bar

Choosing the right grade of steel round bar is essential for ensuring the success of your project. Factors such as strength, corrosion resistance, and ductility play a significant role in this selection.

Common Grades of round steel bars

A36 Steel: Known for its good weldability and strength, it’s commonly used in construction.

304 Stainless Steel: Highly resistant to corrosion, ideal for food processing and chemical industries.

4140 Alloy Steel: Offers high tensile strength and is often used in heavy machinery.

1018 Carbon Steel: A low-carbon steel with good weldability and machinability, commonly used in manufacturing.

Properties of Different Grades

Here’s a deeper look at the mechanical properties of the common grades of round steel bars:

| Grade | Yield Strength (ksi) | Tensile Strength (ksi) | Hardness (HB) | Applications |

|---|---|---|---|---|

| A36 | 36 | 58-80 | 119-174 | Structural components |

| 304 Stainless Steel | 30 | 70-90 | 123-217 | Food processing, medical tools |

| 4140 Alloy Steel | 60 | 90-100 | 197-255 | Heavy machinery, automotive parts |

| 1018 Carbon Steel | 32 | 56-80 | 120-160 | Manufacturing, shafts, gears |

Applications of Steel Round Bar

Steel round bars are utilized across various industries. Understanding these applications can help you choose the right bar for your needs.

Construction and Structural Engineering

In construction, steel round bars are often used as reinforcement bars (rebar) in concrete. They provide added strength and durability to structures like bridges, buildings, and roads. Additionally, they are used in scaffolding and frameworks, enhancing the structural integrity of projects.

Automotive Industry

In the automotive sector, round steel bars are used for manufacturing components such as axles, gears, and crankshafts. Their high strength-to-weight ratio makes them ideal for parts that must withstand significant stress while remaining lightweight.

Machinery and Tooling

Tool makers frequently utilize tool round steel bars due to their exceptional hardness and ability to hold sharp edges, making them suitable for machining tools and dies. These bars are critical in industries that require precision and durability, such as aerospace and manufacturing.

Aerospace Applications

Steel round bars are also employed in aerospace for producing high-stress components, including landing gear and engine parts, where safety and reliability are paramount.

Factors to Consider When Choosing a Steel Round Bar

When selecting a steel round bar, there are several key factors to keep in mind:

Mechanical Properties

Understand the mechanical properties you require, such as yield strength, tensile strength, and ductility, based on your project’s demands. For instance, applications requiring high impact resistance may need tougher materials.

Corrosion Resistance

Depending on the environment where the bar will be used, choose a steel grade that offers sufficient corrosion resistance. For example, stainless steel round bars are often preferred in marine environments due to their excellent resistance to saltwater.

Diameter and Length

Determine the required diameter and length of the steel round bar for your specific application. Custom sizes can often be sourced from suppliers if standard sizes do not meet your needs.

Cost

Consider your budget, as prices can vary significantly based on the steel grade and market conditions. It’s essential to balance quality and cost to ensure a successful project.

Availability

Check the availability of the specific round steel bars you require. Some grades may have longer lead times, which could affect your project timeline.

Common Mistakes to Avoid

When choosing a steel round bar, avoiding certain pitfalls can save you time and resources:

Ignoring Specifications

Always adhere to project specifications and guidelines to ensure compliance and safety. Overlooking these details can lead to costly mistakes.

Overlooking Supplier Quality

Not all suppliers provide high-quality steel. Research and choose reputable suppliers to guarantee the best material for your needs. Look for certifications that verify the quality of their products.

Misestimating Requirements

Accurate calculations are crucial. Misestimating the required diameter or length can lead to project delays and increased costs. Use precise measurements and consider potential wastage.

Neglecting Environmental Conditions

Always consider the environmental conditions where the steel round bar will be used. For example, bars used in coastal areas may need to be more resistant to corrosion than those used indoors.

Underestimating Maintenance

Be aware of the maintenance requirements for the steel round bars you choose. Some may require regular inspections and treatments to prevent rust or degradation.

Conclusion

Selecting the right round steel bars is essential for the success of any project. By understanding the different types, grades, and applications of steel round bars, as well as considering key factors like mechanical properties and corrosion resistance, you can make an informed decision that meets your needs. The right choice can lead to improved performance, longevity, and cost-effectiveness in your projects.

FAQ

What is the difference between carbon steel and alloy Steel Round Bar?

Carbon round steel bars are primarily made of carbon and iron, providing good strength and weldability. Alloy round steel bars contain additional elements like manganese or chromium, enhancing specific properties such as strength and corrosion resistance.

Can steel round bars be cut to size?

Yes, round steel bars can be cut to the required size using various methods, including sawing, shearing, or machining. Ensure the cutting method aligns with the final application’s precision requirements.

What applications require stainless Steel Round Bar?

Stainless round steel bars are ideal for applications that require high corrosion resistance, such as food processing, chemical industries, and marine environments. Their hygienic properties also make them suitable for medical applications.

How should steel round bars be stored?

Round steel bars should be stored in a dry, covered area to prevent rust and corrosion. It’s also advisable to keep them off the ground to avoid moisture exposure. Using pallets or racks can help maintain organization and accessibility.

Is it necessary to treat Steel Round Bar?

Depending on their application, heat treatment may be required to enhance specific properties like strength and hardness. For example, tool round steel bars often undergo heat treatment to improve wear resistance.

How can I ensure I am choosing the right supplier?

To ensure you choose the right supplier, look for industry certifications, read customer reviews, and request samples of their products. Reliable suppliers should have a track record of delivering high-quality materials and excellent customer service.

Choosing the right round steel bar is not just about meeting specifications; it’s about ensuring your project’s success and longevity. With careful consideration and informed choices, you can select the best material to meet your needs.