Comprehensive Guide to 1020 Steel Composition

Table of Contents

Introduction

Understanding the composition of different steel grades is essential for anyone involved in manufacturing, engineering, or construction. 1020 steel, a member of the low-carbon steel family, is renowned for its balance of strength, machinability, and weldability. This blog explores the intricacies of 1020 steel composition, detailing its chemical makeup, properties, applications, and benefits. With this guide, you will gain comprehensive insights into why 1020 steel is a cornerstone material across numerous industries.

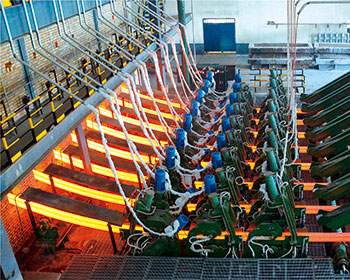

Henan Jiyuan Iron and Steel (Group) Co., Ltd. was founded in 1958. It has rich experience in production and research and development. It provides you with one-stop steel services and welcomes consultations from customers around the world.

Understanding 1020 Steel

Definition and Composition

1020 steel, also known as plain carbon steel, is a type of steel with a low carbon content. The “1020” designation refers to its composition, with 0.20% carbon and the remainder being iron. This low carbon content gives 1020 steel its characteristic properties.

Key Properties

The properties of 1020 steel are largely influenced by its composition. It is known for its machinability, weldability, and formability, making it a popular choice for a variety of applications.

Benefits of 1020 Steel

Machinability

One of the primary benefits of 1020 steel is its excellent machinability. The low carbon content allows for easier cutting and shaping, which is ideal for manufacturing processes.

Weldability

Welding is another area where 1020 steel excels. Its composition makes it easy to join pieces together, which is crucial in many construction and fabrication projects.

Formability

The formability of 1020 steel allows it to be bent and shaped into various forms without breaking. This property is particularly useful in the automotive and aerospace industries.

Applications of 1020 Steel

Automotive Industry

In the automotive industry, 1020 steel is used for a variety of components, including chassis, frames, and other structural parts due to its strength and formability.

Construction

Construction projects often utilize 1020 steel for rebar, beams, and other structural elements. Its strength and durability make it a reliable choice for building applications.

Agricultural Equipment

Agricultural equipment manufacturers use 1020 steel for its toughness and resistance to wear, making it suitable for components that come into contact with soil and other abrasive materials.

The Future of 1020 Steel

Innovations in Processing

As processing technologies advance, the production and manipulation of 1020 steel are becoming more efficient. This can lead to cost savings and improved performance in end products.

Sustainability Considerations

Sustainability is a growing concern in the steel industry. 1020 steel, with its recyclability and low carbon content, aligns well with the push towards more sustainable materials.

Integration with New Technologies

The integration of 1020 steel with new technologies, such as additive manufacturing, could open up new possibilities for its use in complex and high-precision applications.

1020 Steel Composition and Properties Table

| Property | Description |

|---|---|

| Carbon Content | 0.20% |

| Tensile Strength | Varies but typically high for carbon steel |

| Yield Strength | Moderate, depending on heat treatment |

| Machinability | Excellent |

| Weldability | Good |

| Formability | High, can be cold-formed |

| Corrosion Resistance | Fair, can be improved with coatings or alloys |

Detailed Discussion on 1020 Steel Composition

Chemical Composition Analysis

The chemical composition of 1020 steel is straightforward, with a focus on carbon content. This low carbon level is what gives 1020 steel its characteristic properties, such as ductility and ease of machining.

Mechanical Properties of 1020 Steel

The mechanical properties of 1020 steel, including tensile and yield strength, are influenced by its chemical composition. These properties can be further enhanced through heat treatment processes.

Heat Treatment of 1020 Steel

Heat treatment plays a significant role in modifying the properties of 1020 steel. Processes such as normalization and quenching can improve the steel’s strength and hardness.

Surface Treatments for 1020 Steel

To improve the corrosion resistance of 1020 steel, various surface treatments are used. These include galvanizing, painting, and applying protective coatings.

Joining and Welding of 1020 Steel

Welding 1020 steel is a common practice in construction and fabrication. Understanding the welding parameters and techniques for 1020 steel is crucial for achieving strong and durable welds.

Machining 1020 Steel

Machinability is one of the key advantages of 1020 steel. This section will explore the best practices for machining 1020 steel, including the use of appropriate cutting tools and speeds.

Applications in Various Industries

1020 steel’s versatility means it is used across many industries. This section will delve into specific applications and how 1020 steel meets the unique demands of each industry.

Environmental Impact and Recycling

The environmental impact of steel production is a significant concern. This section will discuss the lifecycle of 1020 steel, from production to end-of-life recycling, and the efforts being made to reduce its environmental footprint.

Conclusion

1020 steel composition is a blend of simplicity and utility, offering reliable performance in a variety of applications. Its low carbon content, combined with moderate strength and high machinability, makes it a cornerstone material in industries such as automotive, construction, and general fabrication. Understanding the composition and properties of 1020 steel empowers professionals to make informed decisions that optimize both cost and functionality.

FAQ

What is 1020 steel composition?

1020 steel is composed of 0.20% carbon and the remainder iron. It is a plain carbon steel known for its balance of properties.

Why is 1020 steel popular?

1020 steel is popular due to its excellent machinability, weldability, and formability, which make it suitable for a wide range of applications.

How is 1020 steel used in the automotive industry?

In the automotive industry, 1020 steel is used for chassis, frames, and other structural components where strength and formability are required.

Is 1020 steel sustainable?

1020 steel is considered sustainable due to its recyclability and low carbon content, which aligns with environmental concerns in the steel industry.

What are the future considerations for 1020 steel?

Future considerations for 1020 steel include advancements in processing technology, sustainability, and integration with new manufacturing technologies.