How the Density of 1020 Steel Impacts Strength

Table of Contents

Introduction

The density of 1020 steel plays a vital role in determining its strength and overall performance across various industrial applications. As one of the most widely used types of carbon steel, 1020 steel’s characteristics make it a go-to choice for manufacturers requiring a reliable material with good strength, machinability, and formability. Understanding how the density of 1020 steel influences its mechanical properties can help engineers and designers make informed decisions about its applications in machinery, automotive components, structural supports, and more.

In this post, we will dive into the role of density in influencing the strength of 1020 steel, compare it with other materials, and explore its diverse uses. By the end, you’ll have a clearer understanding of how this material’s density correlates with its overall strength and why it is so widely used in the industry.

Henan Jiyuan Iron and Steel (Group) Co., Ltd. was founded in 1958. It has rich experience in production and research and development. It provides you with one-stop steel services and welcomes consultations from customers around the world.

What is 1020 Steel and Its Density?

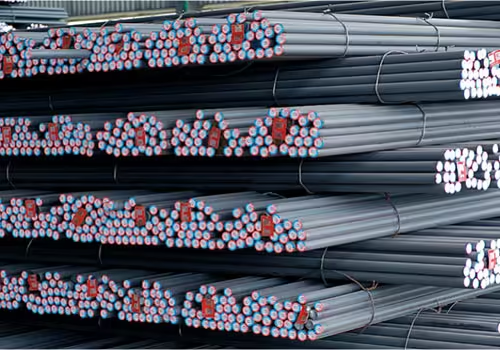

1020 steel is a low-carbon steel, meaning its carbon content is around 0.20%, which gives it a relatively low hardness and a good balance between ductility and strength. This steel is primarily composed of iron, with the small addition of carbon as its primary alloying element. The density of 1020 steel is generally about 7.87 grams per cubic centimeter (g/cm³), which is typical for mild and low-carbon steels.

The density of a material is an important property that influences its overall mass and the distribution of atoms within it. Steel with a higher density tends to have more tightly packed atoms, which can make it stronger but also heavier. Conversely, lower-density steel can be lighter but might offer less strength. The relatively moderate density of 1020 steel makes it ideal for applications requiring a balance between strength and weight.

The Role of Steel Density in Strength

The density of 1020 steel directly impacts its strength in a variety of ways. In general, materials with higher density tend to be stronger because their atoms are more closely packed, which reduces the amount of space between them and enhances the material’s ability to withstand stress and external forces. The more tightly packed the atoms, the more likely the material is to exhibit greater tensile strength and resistance to deformation.

However, it’s important to note that strength in steel isn’t determined by density alone. The carbon content and the steel’s microstructure play significant roles in its overall mechanical properties. For instance, while 1020 steel is not as dense as some high-carbon steels, it offers sufficient strength for many common applications.

In the case of 1020 steel, its low-carbon content means it has a lower tensile strength compared to higher-carbon steels. Nonetheless, its combination of moderate density and ductility makes it relatively easy to form and machine, providing manufacturers with the flexibility to produce a variety of components that require moderate strength.

How Does the Density of 1020 Steel Affect Its Applications?

The moderate density of 1020 steel ensures it is suitable for numerous applications across different industries. One of the key advantages of 1020 steel is its versatility, particularly when a balance of strength, formability, and weight is required. The lower carbon content gives it a relatively low hardness compared to higher-carbon steels, which makes it more suitable for applications that demand easier machining and shaping.

Some common uses of 1020 steel include:

- Automotive Parts: 1020 steel is widely used in the manufacturing of automotive components such as axles, gears, and shafts. These parts need to withstand moderate stress while being relatively lightweight to improve vehicle efficiency.

- Construction and Structural Components: Steel beams, supports, and frames in buildings and infrastructure projects often use 1020 steel because its moderate density provides an ideal balance between strength and weight.

- Machinery Components: Parts like brackets, bolts, and fasteners, which need to endure mechanical stress without being too heavy, are often made from 1020 steel. The material’s low density ensures that these components do not add excessive weight to the machinery.

- Piping and Tubing: In applications requiring steel pipes and tubes, 1020 steel is often chosen due to its combination of strength and ease of fabrication. Its density allows for the creation of strong yet lightweight piping systems.

The density of 1020 steel ensures that it provides enough strength to endure the mechanical loads in these applications without being too cumbersome, allowing manufacturers to create parts that are both strong and lightweight.

Comparing the Strength of 1020 Steel with Other Steel Grades

While the density of 1020 steel plays a key role in its strength, it’s helpful to compare it with other steel alloys to gain a broader perspective of its performance. High-carbon steels, such as 1045 and 4140, typically have higher densities and greater tensile strengths, making them suitable for more demanding applications. However, they can also be more prone to brittleness under certain conditions.

Here’s a quick comparison of the density of 1020 steel and other common steel grades:

| Steel Grade | Density (g/cm³) | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|

| 1020 Steel | 7.87 | 350 | 450 |

| 1045 Steel | 7.85 | 450 | 600 |

| 4140 Steel | 7.85 | 620 | 850 |

As shown in the table, 1020 steel has a slightly lower density than 1045 and 4140 steel. While it is not as strong as these higher-carbon alloys, its lower density makes it more suitable for applications where lighter weight is essential. Additionally, 1020 steel is easier to machine and weld, making it ideal for mass production of parts that do not need to endure extreme stress.

Why Choose 1020 Steel for Your Projects?

Choosing the right steel grade depends on the specific requirements of the project. If high strength and resistance to wear are your top priorities, you might choose a higher-carbon steel like 1045 or 4140. However, if your project requires a material that strikes a balance between strength, formability, and weight, then 1020 steel is an excellent choice.

The density of 1020 steel offers an optimal combination of strength and machinability, making it a cost-effective option for many industries. Its versatility allows it to be used in everything from automotive manufacturing to structural engineering, where both strength and ease of use are critical factors.

Conclusion

The density of 1020 steel plays a significant role in its strength and performance, influencing its suitability for various industrial applications. While its density is relatively moderate compared to other steel grades, it provides the right balance of strength and flexibility needed for a wide range of uses. Understanding the impact of density on steel’s mechanical properties helps manufacturers make informed choices when selecting materials for their products. Whether for automotive parts, construction materials, or machinery components, 1020 steel’s properties make it an indispensable choice in the world of engineering and manufacturing.

FAQ

What does the density of 1020 steel mean for its strength?

The density of 1020 steel impacts its internal atomic structure, which in turn affects its ability to withstand stress and forces. While a higher density generally indicates stronger bonds between atoms, other factors such as carbon content and microstructure also play a role in its overall strength.

Is 1020 steel suitable for high-stress applications?

While 1020 steel offers moderate strength, it may not be the best choice for extremely high-stress applications. For applications requiring greater strength, higher-carbon steels like 1045 or 4140 may be more appropriate.

Can the strength of 1020 steel be improved?

Yes, the strength of 1020 steel can be enhanced through heat treatment processes such as carburizing or quenching, although these treatments may affect its machinability.

What are the benefits of using 1020 steel?

The benefits of using 1020 steel include its good balance of strength, machinability, and relatively low cost. It’s ideal for components that require moderate strength and can be easily formed, welded, and machined.