Is 4140 Chromoly Steel the Best Choice for Your Industry?

Table of Contents

Introduction

When it comes to selecting materials for high-performance applications, steel is often the material of choice due to its versatility, strength, and durability. Among the various types of steel, 4140 chromoly steel stands out as one of the most popular and widely used alloys in industries that require high-strength materials. From manufacturing to automotive and aerospace, 4140 chromoly steel is commonly found in critical components such as gears, shafts, and structural parts.

But what makes 4140 chromoly steel so special? And is it the best option for your specific industrial needs? In this blog post, we will explore the properties of 4140 chromoly steel, its advantages, and how it compares to other steel alloys. Additionally, we will provide insights into how to choose the best material for your industry’s requirements.

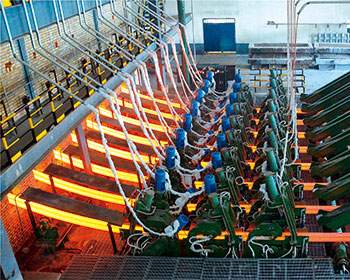

Henan Jiyuan Iron and Steel (Group) Co., Ltd. was founded in 1958. It has rich experience in production and research and development. It provides you with one-stop steel services and welcomes consultations from customers around the world.

What is 4140 Chromoly Steel?

4140 chromoly steel is a low-alloy steel that contains chromium and molybdenum as its primary alloying elements. The “chromoly” designation comes from the combination of these two elements, which give the steel its unique properties. The steel is commonly used in applications where high strength, toughness, and wear resistance are required.

- Chromium (Cr): Improves hardness, corrosion resistance, and strength.

- Molybdenum (Mo): Enhances toughness, hardness, and resistance to wear.

This alloy is available in different forms, including bars, rods, and sheets, and it is frequently heat-treated to achieve specific mechanical properties that meet the demands of various industries.

Properties of 4140 Chromoly Steel

Strength and Hardness

One of the most significant advantages of 4140 chromoly steel is its strength. This steel is known for its ability to withstand high stress and mechanical forces without deforming. It offers a high tensile strength (around 95,000 psi) and yield strength (about 60,000 psi) when heat-treated. This makes it ideal for applications requiring materials that can handle heavy loads and intense pressure.

The steel also possesses excellent hardness properties, which is why it is commonly used in manufacturing parts that must endure wear and tear, such as gears, axles, and engine components.

Toughness and Durability

Another benefit of 4140 chromoly steel is its toughness. It has a strong resistance to cracking and breaking under impact or fatigue, which is crucial in industries such as automotive and aerospace. Its ability to perform well in low-temperature conditions further adds to its durability, making it suitable for use in extreme environments.

Machinability

While 4140 chromoly steel is known for its toughness and strength, it can still be machined with ease, provided the appropriate tools and techniques are used. This makes it easier to fabricate complex parts, such as shafts, gears, and connectors, that are often required in high-performance industries.

Heat Resistance

The presence of chromium and molybdenum in 4140 chromoly steel improves its resistance to heat. It can withstand high temperatures without losing its strength, which is critical in applications involving engines, motors, and heavy-duty machinery.

Corrosion Resistance

Though not as resistant to corrosion as stainless steel, 4140 chromoly steel offers moderate corrosion resistance due to the presence of chromium. However, it is still recommended to apply protective coatings, such as plating or painting, for environments with high humidity or corrosive agents.

Table: Comparison of 4140 Chromoly Steel with Other Steel Alloys

| Property | 4140 Chromoly Steel | 1045 Carbon Steel | Alloy 8620 Steel |

|---|---|---|---|

| Tensile Strength | 95,000 psi | 85,000 psi | 85,000 psi |

| Yield Strength | 60,000 psi | 60,000 psi | 60,000 psi |

| Hardness | 28-32 HRC | 18-22 HRC | 20-30 HRC |

| Toughness | High | Moderate | High |

| Corrosion Resistance | Moderate | Low | Low |

| Heat Resistance | High | Moderate | Moderate |

| Machinability | Good | Excellent | Moderate |

Advantages of 4140 Chromoly Steel in Various Industries

Automotive Industry

In the automotive sector, 4140 chromoly steel is used in a variety of components that need to withstand high stress and wear. These include:

- Axles and shafts that require high tensile strength to handle heavy loads.

- Roll cages for racing cars, where safety and durability are crucial.

- Gears and transmission parts, which benefit from the alloy’s ability to resist deformation under high pressure.

The combination of toughness and machinability makes 4140 chromoly steel an excellent choice for automotive applications, where performance and longevity are key.

Aerospace Industry

In the aerospace sector, the strength-to-weight ratio is critical. 4140 chromoly steel’s ability to perform under high temperatures and stresses makes it suitable for use in parts like:

- Landing gear components.

- Aircraft structural parts that must endure harsh conditions.

- Engine components where heat resistance is required.

The steel’s ability to maintain its integrity under extreme stress and temperature makes it a reliable material for aerospace applications.

Construction and Machinery

4140 chromoly steel is often used in heavy machinery and construction equipment. Its durability and strength make it an ideal material for:

- Construction equipment such as bulldozers, excavators, and cranes.

- Heavy-duty gears and shafts that endure high mechanical stress.

- Machine frames that need to resist wear over extended periods.

Oil and Gas Industry

In the oil and gas sector, where equipment must endure extreme conditions, 4140 chromoly steel is used in:

- Drill bits and downhole tools.

- Pipeline components that require high strength and toughness.

- Pump shafts and valves that are exposed to harsh environments.

The high strength and resistance to impact and fatigue make it ideal for the demanding applications in the oil and gas industry.

How to Choose the Right 4140 Chromoly Steel for Your Industry

When selecting 4140 chromoly steel for your industrial needs, it’s important to consider the specific requirements of your application. Some factors to take into account include:

- Strength and hardness requirements.

- Corrosion resistance needs (whether the component will be exposed to harsh environments).

- Heat resistance if the application involves high temperatures.

- Machinability for complex or high-precision parts.

- Availability of different grades of 4140 chromoly steel based on the required specifications.

Consulting with a material expert or supplier is a good practice to ensure that the right type of 4140 chromoly steel is chosen for the task at hand.

Conclusion

4140 chromoly steel is a top choice for industries requiring strength, durability, and high performance. Its combination of tensile strength, toughness, and heat resistance makes it an ideal material for automotive, aerospace, construction, and oil and gas industries, among others. However, it is essential to consider your specific needs when selecting steel for your application, as different alloy steels may offer varying properties that better suit your requirements.

By understanding the properties, advantages, and limitations of 4140 chromoly steel, you can make an informed decision about whether it’s the best choice for your industry. Investing in the right material will ensure the longevity and success of your equipment and components.

FAQ

What is 4140 chromoly steel used for?

4140 chromoly steel is used in a wide range of applications, including automotive parts, aerospace components, machinery, and tools. It is known for its strength, toughness, and resistance to wear, making it ideal for high-stress environments.

How does 4140 chromoly steel compare to 1045 carbon steel?

Compared to 1045 carbon steel, 4140 chromoly steel has higher tensile strength, better toughness, and improved resistance to heat. This makes 4140 ideal for more demanding applications that require superior performance.

Is 4140 chromoly steel resistant to corrosion?

4140 chromoly steel has moderate corrosion resistance due to the chromium content, but it is not as resistant as stainless steel. For environments with high moisture or corrosive elements, protective coatings or plating may be necessary.

Can 4140 chromoly steel be welded?

Yes, 4140 chromoly steel can be welded, though it requires proper techniques and pre-heating to avoid cracking. Welding should be done by an experienced welder to ensure the material maintains its strength and toughness.

How do I choose the right grade of 4140 chromoly steel for my project?

Choosing the right grade of 4140 chromoly steel depends on the specific requirements of your project, including strength, hardness, machinability, and resistance to heat and corrosion. Work with an experienced supplier to ensure you select the best grade for your needs.