Is Your 4140 Annealed Hardness Failing? 5 Signs

Table of Contents

Introduction

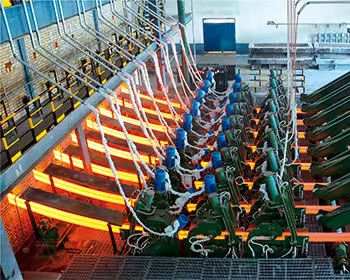

4140 steel is a versatile alloy known for its high tensile strength, good fatigue resistance, and excellent machinability. When properly annealed, 4140 steel exhibits a stable and uniform hardness that makes it suitable for various applications, such as automotive parts, machinery components, and construction tools. The term 4140 annealed hardness refers to the steel’s hardness level after undergoing an annealing process, which reduces internal stresses and improves workability.

Understanding and maintaining the correct 4140 annealed hardness is crucial for ensuring long-term performance and reliability. However, hardness can degrade over time due to improper handling, environmental conditions, or manufacturing flaws. Recognizing the signs of failing hardness early on can save costs, enhance safety, and prevent major operational disruptions.

In this comprehensive guide, we will explore the top five signs your 4140 annealed hardness may be failing, how to detect them, and what corrective actions you can take.

Sign #1 – Inconsistent Machining Performance

One of the first indicators of problems with 4140 annealed hardness is irregular machining performance. When the material is at its optimal hardness level, it allows for smooth, predictable cutting and shaping. However, if you begin to notice issues such as increased tool wear, surface finish inconsistencies, or unusual resistance during machining, it might suggest that the hardness is not uniform or has drifted from the expected range.

You might also find that machining takes longer than expected, or that more frequent tool changes are necessary, which can drive up production costs. This is especially true when dealing with large-scale manufacturing runs, where inconsistencies can lead to significant waste and downtime.

Monitoring the machining feedback and comparing it with historical data can help identify abnormalities. In some cases, automated monitoring systems can detect increased torque or temperature during cutting, which could be an indirect indication of hardness issues. Conducting regular hardness tests after each batch processing can also prevent widespread issues.

Sign #2 – Structural Deformations and Failures

Another alarming sign of failing 4140 annealed hardness is the occurrence of structural deformations or premature failures. Components made from this alloy should demonstrate sufficient strength under normal working loads. If parts begin to warp, crack, or bend easily, it often points to improper annealing or degradation of hardness over time.

These failures may not always be immediately visible. They can begin as micro-cracks or slight deformations that progressively worsen under repetitive stress. Applications involving high torque, vibration, or dynamic loads are especially susceptible to revealing the consequences of inadequate 4140 annealed hardness.

Failures may also result from excessive stress concentrations, thermal cycling, or corrosion, all of which can weaken the internal structure. Regular visual inspections combined with non-destructive testing methods, such as ultrasonic or magnetic particle testing, can help detect early signs. A metallurgical analysis combined with hardness testing can provide a clearer picture of the material’s current state.

Sign #3 – Discrepancies in Hardness Testing

Routine hardness testing is essential for quality control in any metalworking environment. If you notice discrepancies or fluctuations in test results across different areas of the same workpiece, this is a strong indication that the 4140 annealed hardness is not consistent. Testing methods such as Rockwell or Brinell can be employed to measure surface and core hardness.

Even when a workpiece meets general specifications, variability within localized areas can result in unexpected weak spots. This becomes critical in parts subjected to cyclic loading, where small inconsistencies can lead to fatigue failures. Thus, it’s not just the average hardness that matters but also the distribution across the entire component.

Table – Acceptable Hardness Ranges for 4140 Annealed Steel

| Hardness Test Method | Acceptable Range (Annealed) |

|---|---|

| Rockwell B | 85 – 95 |

| Brinell | 197 – 217 |

| Vickers | 200 – 220 |

These values represent the typical range for 4140 steel in an annealed condition. Consistent results within this range signify proper processing and material integrity. Deviations may require re-annealing or further investigation. Additionally, make sure the testing conditions are standardized and that the instruments are properly calibrated to avoid inaccurate readings.

Sign #4 – Unexpected Wear in Service Conditions

When 4140 steel components exhibit faster-than-normal wear during their operational life, it may indicate compromised hardness. The wear resistance of annealed 4140 is balanced to provide both machinability and durability. If this balance is disrupted, components may degrade quickly under friction or load-bearing conditions.

For instance, shafts, gears, or bushings made from 4140 steel should show controlled wear even after extended usage. If there’s rapid surface deterioration, scoring, or flaking, it’s likely due to deviations in hardness. Surface pitting, metal fatigue cracks, or abrasive erosion are also red flags that the material may not be holding up as expected.

Operators should inspect parts for signs of abrasion, pitting, or surface breakdown. Analyzing these wear patterns can reveal whether the component’s 4140 annealed hardness meets application requirements. In high-wear environments, wear simulation testing can also be employed to assess material durability under expected service conditions.

In many cases, metallurgical evaluations paired with wear analysis can pinpoint the root cause. If material hardness is too low, reprocessing or selecting a different heat treatment path may restore service life expectations. Preventive maintenance schedules should include regular evaluations of wear-prone parts, especially when used in high-friction or load-bearing roles.

Sign #5 – Poor Heat Treatment Response

The ability of 4140 steel to respond to subsequent heat treatments, such as quenching or tempering, relies heavily on its initial annealed state. If the material shows a poor or inconsistent response to these processes, it could be due to an initial failure in achieving proper 4140 annealed hardness.

Indicators of poor response include uneven hardness post-treatment, brittleness, or lack of desired mechanical properties. This can lead to severe implications for structural integrity, especially when the steel is used in safety-critical applications.

This problem often stems from insufficient annealing cycles, rapid cooling, or improper furnace calibration. Inadequate soaking time or non-uniform temperature distribution during annealing may also contribute to the issue. Additionally, surface contamination or decarburization during processing can negatively affect heat treatment results.

To mitigate this, facilities should implement controlled heating profiles and ensure temperature uniformity across the furnace chamber. Monitoring equipment should be calibrated regularly, and process parameters should be logged and reviewed after each batch. Recording these cycles for traceability can also help troubleshoot future issues and uphold compliance with industry standards.

Collaborating with metallurgical experts or investing in advanced thermal analysis tools can further enhance consistency and quality. By addressing poor heat treatment response early, manufacturers can avoid costly part rejection and maintain structural performance in critical applications.

Preventive Measures and Best Practices

To avoid issues related to failing 4140 annealed hardness, manufacturers and engineers should adopt several best practices:

- Routine hardness testing at different production stages, including after annealing and before final machining.

- Proper storage to prevent moisture exposure, oxidation, or temperature fluctuations that can alter microstructure.

- Accurate heat treatment protocols with verified and regularly calibrated equipment, ensuring consistent annealing cycles.

- Detailed material certification from suppliers, including chemical composition and previous heat treatment history.

- Training for operators and quality inspectors in recognizing early signs of material failure, such as abnormal wear or deformation.

- Statistical Process Control (SPC) and other quality management tools to detect trends or process drifts early.

- Third-party audits or metallurgical consultations to independently verify hardness consistency and structural integrity.

Preventive strategies like these ensure that the material’s hardness remains within specification, which in turn upholds the reliability, safety, and cost-efficiency of the end products. Instituting a culture of continuous monitoring and process optimization can significantly reduce rework, scrap rates, and potential failures in service.

Implementing these steps can greatly enhance material reliability and extend component life.

Conclusion

4140 annealed hardness plays a vital role in determining the success and longevity of components made from this alloy. By being vigilant about signs such as inconsistent machining, structural failures, testing discrepancies, unusual wear, and poor heat treatment response, industries can take early action to mitigate risks.

Proper hardness ensures balanced machinability, strength, and performance. Consistently monitoring and maintaining these properties not only ensures product quality but also reduces downtime and repair costs. If your system exhibits any of the signs discussed above, a detailed inspection and corrective strategy should be your next step.

FAQ

What is the ideal 4140 annealed hardness?

The typical range for 4140 steel in an annealed condition is Rockwell B 85–95 or Brinell 197–217.

How do I test 4140 annealed hardness?

Common methods include Rockwell, Brinell, and Vickers hardness tests. Consistent testing across different areas ensures reliability.

Can failed hardness be corrected?

In many cases, yes. Re-annealing or additional heat treatment can help restore proper hardness levels.

Does improper storage affect hardness?

Yes, environmental conditions such as humidity and temperature fluctuations can impact the microstructure and degrade hardness.

Is 4140 annealed hardness important for all industries?

Absolutely. From automotive to aerospace and general engineering, maintaining the right hardness is crucial for performance and safety.