Q235 Hardness and Its Impact on Steel Performance

Table of Contents

Introduction

Q235 steel is one of the most commonly used materials in the construction, automotive, and manufacturing industries. A versatile mild steel grade, it is valued for its excellent weldability, formability, and moderate strength. However, one of the most critical characteristics that significantly impacts its performance is its hardness. Understanding Q235 hardness is crucial for manufacturers and engineers when choosing the right materials for specific applications. In this article, we will explore Q235 hardness in detail, discuss how it affects steel performance, and provide guidance on how to measure and manage hardness for optimal use.

By the end of this blog, you will have a clearer understanding of how Q235 hardness influences the performance, durability, and functionality of steel in various applications.

What is Q235 Steel?

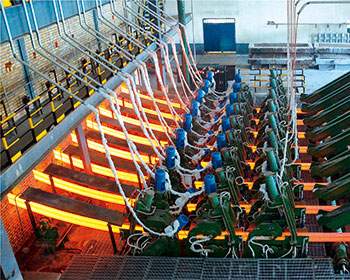

Q235 is a Chinese standard carbon steel that is widely used for general manufacturing and structural purposes. It is often compared to steel grades like A36, as both are used for similar applications, including the construction of bridges, buildings, and machinery. Q235 steel has different subtypes (Q235A, Q235B, Q235C, and Q235D), each with varying specifications for strength and toughness.

Key Properties of Q235 Steel

- Chemical Composition: Primarily composed of carbon, with small amounts of manganese, sulfur, and phosphorus.

- Tensile Strength: Ranges from 370 to 500 MPa depending on the subtype.

- Yield Strength: Around 235 MPa.

- Weldability: Excellent, making it ideal for welding applications.

- Corrosion Resistance: Moderate resistance to corrosion, suitable for environments that are not too harsh.

Despite its advantages, the hardness of Q235 steel directly affects its performance in various environments. Hardness, in simple terms, refers to a material’s resistance to indentation, scratching, and wear. It influences the steel’s durability, machinability, and overall strength.

Q235 Hardness: What It Means and How It Affects Steel Performance

Understanding Q235 Hardness

The hardness of Q235 steel is an essential factor that affects its performance in specific applications. It is typically measured using different scales, with the most common being the Brinell hardness number (BHN), Rockwell hardness, and Vickers hardness. These tests measure the material’s resistance to deformation under a specific load.

The hardness of Q235 steel generally ranges from 120 to 170 HB (Brinell hardness), depending on the type and the heat treatment process applied. This range allows it to be used in a variety of applications where moderate strength and resistance to wear are needed.

Factors Influencing Q235 Hardness:

- Chemical Composition: The amount of carbon and other alloying elements can influence the hardness.

- Heat Treatment: Processes like annealing, quenching, and tempering can alter the hardness of Q235 steel.

- Cold Working: Bending and other cold-working processes can increase hardness.

- Subtype of Q235: Different Q235 subtypes may have slightly varying hardness levels due to differing alloy compositions.

How Q235 Hardness Affects Durability and Wear Resistance

One of the most noticeable impacts of Q235 hardness is its effect on the durability of the material. Harder steel is generally more resistant to wear, meaning it will last longer when subjected to repeated friction or contact with other materials.

For example, when Q235 steel is used for structural applications, it needs to withstand environmental stresses, heavy loads, and potential abrasion. A higher hardness can increase the material’s ability to endure such conditions. However, too much hardness can make the steel brittle, which is why a balance between hardness and toughness is necessary for optimal performance.

Q235 Hardness and Its Impact on Machinability

While a higher hardness generally improves wear resistance, it can also reduce machinability. Harder steel requires more energy and specialized equipment to cut, drill, or weld, which may increase processing time and costs. Understanding the hardness of Q235 steel helps manufacturers select the correct machining tools and processes.

For instance, when machining Q235 steel with a hardness of 140 HB, operators would choose tools with high durability, like carbide inserts, and use slower cutting speeds to avoid tool wear. Lower-hardness Q235 steel, such as Q235A, would be easier to machine but may not offer the same wear resistance or strength.

Q235 Hardness and Structural Integrity

The structural integrity of steel components used in construction and machinery is highly dependent on the hardness of the material. For example, Q235 steel used in bridges or buildings needs to have the right balance of strength and hardness to ensure it can handle external forces without bending or failing.

The yield strength and tensile strength of Q235 steel are linked to its hardness. Higher hardness increases these properties, but extreme hardness might compromise ductility, making the steel prone to cracks under stress. Thus, Q235 steel’s hardness directly influences how well it performs in critical applications, where both strength and flexibility are necessary.

Measuring Q235 Hardness

There are several methods to measure the hardness of Q235 steel, each providing unique insights into the material’s properties. The most commonly used hardness tests are:

| Hardness Test | Description | Scale | Application |

|---|---|---|---|

| Brinell Test | A steel ball is pressed into the steel surface under load. | BHN (Brinell Hardness Number) | Used for thicker materials with coarse grain. |

| Rockwell Test | Measures the depth of penetration of an indenter under load. | HRB or HRC | Fast and used for materials of varying thickness. |

| Vickers Test | Measures the size of the indentation left by a diamond indenter. | HV (Vickers Hardness) | Used for materials with small thickness or fine-grain structures. |

Each test provides valuable data for manufacturers and engineers to ensure that the steel’s hardness meets the specific needs of their applications.

Applications of Q235 Steel Based on Hardness

Construction Industry

Q235 steel is widely used in construction because of its favorable balance of hardness and weldability. Depending on the required strength and toughness for the application, such as beams, columns, and structural frames, the hardness of Q235 can be adjusted through heat treatment processes to optimize its performance.

Automotive Industry

In the automotive sector, Q235 steel is often used for components like body parts and frames. The hardness of Q235 impacts the vehicle’s overall durability, resistance to wear, and the ability to withstand impact forces.

Manufacturing Equipment

Q235 steel’s hardness makes it suitable for manufacturing equipment and machinery components that require moderate strength and wear resistance. However, in some cases, the hardness may need to be adjusted based on the specific part’s function and usage.

Conclusion

Q235 hardness plays a crucial role in determining the performance, durability, and machinability of steel. By understanding how the hardness of Q235 affects its structural integrity, wear resistance, and overall application, businesses can make better decisions on material selection, processing methods, and cost-effectiveness.

Ultimately, the right balance of hardness in Q235 steel ensures optimal performance across various industries. Whether you are building a structure, manufacturing equipment, or creating automotive parts, selecting the right Q235 steel with the correct hardness is essential for achieving desired results.

FAQ

What is the typical hardness of Q235 steel?

The hardness of Q235 steel typically ranges from 120 to 170 HB (Brinell hardness), depending on the specific subtype and processing methods.

How is Q235 hardness measured?

Q235 hardness is measured using methods such as the Brinell test, Rockwell test, or Vickers test, each of which provides different insights into the steel’s hardness properties.

What factors affect the hardness of Q235 steel?

Factors that influence Q235 hardness include chemical composition, heat treatment processes, and the level of cold working the steel undergoes.

Why is Q235 hardness important for structural applications?

Q235 hardness is important for structural applications because it determines the steel’s ability to withstand wear, impact, and environmental stresses without compromising its strength or ductility.

Can Q235 steel hardness be increased?

Yes, Q235 steel hardness can be increased through heat treatment processes like quenching, tempering, or annealing, depending on the desired properties for the specific application.

How does Q235 hardness affect machinability?

Higher hardness can reduce machinability, making it more difficult to cut, drill, or weld. For machining Q235 steel, operators often use tools with higher durability and adjust cutting speeds accordingly.

Is Q235 steel suitable for outdoor applications?

Yes, Q235 steel can be used for outdoor applications, but it has moderate corrosion resistance. For environments with high exposure to corrosion, additional protective coatings or materials with better corrosion resistance may be necessary.