Understanding Round Bars: Types and Uses Explained

Introduction

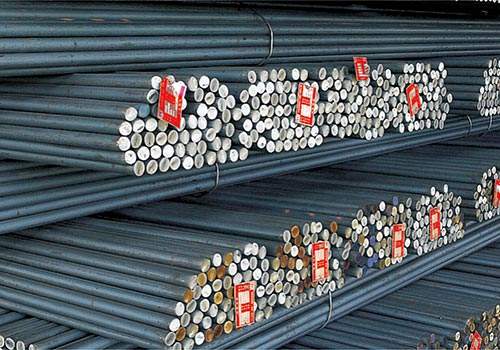

Round bars are a fundamental type of steel product widely used across various industries. Their unique shape and properties make them suitable for numerous applications, ranging from construction to manufacturing. This blog will delve into the different types of round bars, their composition, and their applications. We will explore the importance of understanding round bars and how they contribute to various engineering and construction projects.

What Are Round Bars?

Round stocks are long, cylindrical pieces of metal, typically made from steel, aluminum, or other alloys. They come in various diameters and lengths, offering versatility for different applications. Round stocks are manufactured through processes such as rolling, forging, and extrusion. Their uniform shape allows for easy machining and welding, making them essential in engineering and manufacturing.

Types of Round Bars

There are several types of round stocks, each with unique properties and applications. Understanding these types can help you choose the right material for your project.

Carbon Steel Round Bars

Carbon steel round stocks are known for their strength and durability. The carbon content typically ranges from low to high, affecting the hardness and strength of the bars. These are commonly used in construction, automotive, and machinery applications.

Alloy Steel Round Bars

Alloy steel round stocks contain additional alloying elements like chromium, molybdenum, and nickel. These elements enhance specific properties such as corrosion resistance and toughness. Alloy steel round stocks are used in demanding environments, including oil and gas and aerospace industries.

Stainless Steel Round Bars

Stainless steel round stocks are resistant to corrosion and staining, making them ideal for applications in harsh environments. They are widely used in food processing, chemical, and pharmaceutical industries.

Tool Steel Round Bars

Tool steel round stocks are designed for high wear resistance and toughness. They are commonly used in the manufacturing of cutting tools and dies, where strength and durability are critical.

Aluminum Round Bars

Aluminum round stocks are lightweight and resistant to corrosion. They are commonly used in applications where weight savings are essential, such as in aerospace and automotive components.

Table 1: Properties of Different Types of Round Bars

| Type | Material | Strength | Corrosion Resistance | Common Uses |

|---|---|---|---|---|

| Carbon Steel | Steel | High | Moderate | Construction, Automotive |

| Alloy Steel | Steel | Very High | Good | Aerospace, Oil & Gas |

| Stainless Steel | Stainless Steel | Moderate | Excellent | Food Processing, Chemical |

| Tool Steel | Tool Steel | Very High | Poor | Cutting Tools, Dies |

| Aluminum | Aluminum | Low | Good | Aerospace, Automotive |

Applications of Round Bars

Round stocks are utilized in various industries due to their versatility. Below are some common applications:

Construction

In the construction industry, round stocks are used in the fabrication of structural components, reinforcement bars, and beams. Their strength and durability make them suitable for supporting heavy loads.

Automotive Manufacturing

Round stocks play a vital role in automotive manufacturing. They are used in the production of axles, shafts, and other critical components that require high strength and precision.

Machinery and Equipment

Round stocks are often used to manufacture parts for machinery and equipment. Their uniform shape allows for easy machining and fitting into complex assemblies.

Aerospace

In aerospace applications, round stocks are used for structural components and fasteners. The lightweight and strong nature of materials like aluminum round bars makes them ideal for this industry.

Oil and Gas Industry

Round stocks are essential in the oil and gas industry, where they are used for drilling equipment, valves, and other components that must withstand extreme conditions.

The Importance of Quality in Round Bars

The quality of round stocks is crucial for ensuring their performance in various applications. High-quality round bars undergo rigorous testing and quality assurance processes to meet industry standards. Factors such as material composition, manufacturing processes, and heat treatment can significantly affect the properties of round bars.

Material Composition

The composition of the material used in round stocks determines their mechanical properties. It’s essential to select the right type of round bar based on the specific requirements of the application.

Manufacturing Process

The manufacturing process can influence the final properties of round bars. Processes such as rolling, forging, or extrusion can affect their strength, ductility, and surface finish.

Heat Treatment

Heat treatment processes can enhance the mechanical properties of round bars. Processes such as quenching and tempering are commonly used to increase hardness and strength.

Conclusion

Understanding round stocks, their types, and their applications is vital for selecting the right materials for various projects. Their versatility and strength make them indispensable in many industries, including construction, automotive, and aerospace. By recognizing the importance of quality in round stocks, manufacturers and engineers can ensure their products meet the required standards and perform reliably in their intended applications.

FAQ

What are round stocks used for?

Round bars are used in construction, automotive manufacturing, machinery, aerospace, and oil and gas industries, among others.

What types of materials are used for round stocks?

Common materials for round bars include carbon steel, alloy steel, stainless steel, tool steel, and aluminum.

How do I choose the right round stocks for my application?

Choosing the right round bar depends on factors such as strength requirements, corrosion resistance, and specific application needs. Consult material specifications and industry standards.

Can round bars be machined?

Yes, round bars can be easily machined, making them suitable for various engineering applications.

What is the significance of round stocks in manufacturing?

Round stocks are essential for creating precise components and structures, providing strength and durability across multiple industries.

By comprehensively understanding round bars and their properties, industries can make informed decisions about material selection and application, ensuring optimal performance and reliability in their projects.