What Is 1020 Steel?

Table of Contents

Introduction

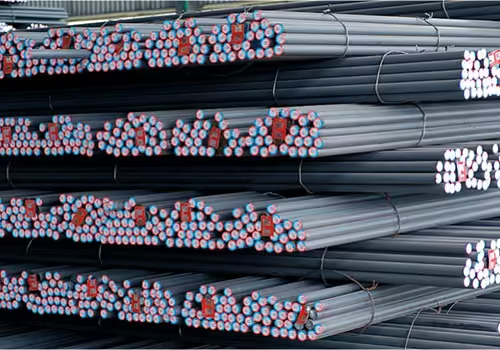

Steel is a fundamental material in various industries, from construction to automotive manufacturing. Among the many types of steel available, 1020 steel stands out due to its excellent mechanical properties and versatile applications. But what is 1020 steel, and why is it so widely used? This article explores the characteristics, composition, applications, and benefits of this remarkable material.

Henan Jiyuan Iron and Steel (Group) Co., Ltd. was founded in 1958. It has rich experience in production and research and development. It provides you with one-stop steel services and welcomes consultations from customers around the world.

Understanding the Composition and Properties of 1020 Steel

1020 steel is a low-carbon steel known for its good machinability and weldability. The composition of this material includes:

- Carbon Content: Approximately 0.18-0.23%

- Manganese Content: Around 0.30-0.60%

- Phosphorus and Sulfur: Typically less than 0.04%

Due to its low carbon content, What Is 1020 Steel offers high ductility and excellent toughness, making it ideal for many industrial applications. What Is 1020 Steel is commonly used in cold-rolled or hot-rolled forms and can be easily shaped, cut, or welded without compromising its integrity.

Key Mechanical Properties of 1020 Steel

The mechanical properties of 1020 steel make it suitable for a variety of engineering applications. Below is a table outlining its primary mechanical characteristics:

| Property | Value |

|---|---|

| Tensile Strength | 394-551 MPa |

| Yield Strength | 205 MPa |

| Elongation at Break | 15-30% |

| Hardness (Brinell) | 111-160 |

| Density | 7.87 g/cm³ |

| Modulus of Elasticity | 200 GPa |

“What Is 1020 Steel? These properties indicate that 1020 steel, which is classified as a low-carbon steel, is relatively soft compared to high-carbon steels. However, What Is 1020 Steel known for is its excellent formability and strength, making it an ideal choice for a variety of general-purpose applications.”

Applications of 1020 Steel in Various Industries

Due to its favorable characteristics, 1020 steel is widely used across different industries. Some of its most common applications include:

Automotive Industry

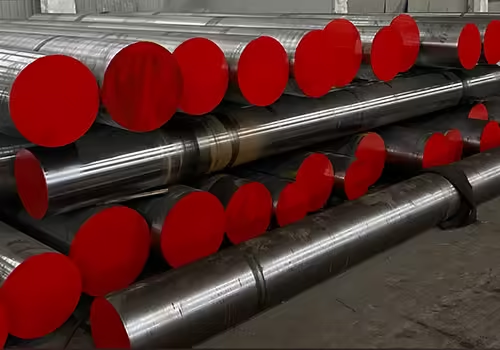

1020 steel is extensively used in manufacturing automotive components such as gears, axles, and crankshafts. Its machinability and durability make it a preferred choice for these critical parts.

Construction Sector

In the construction industry, 1020 steel is used for structural components, including beams, columns, and support brackets. Its strength and toughness provide reliability in load-bearing applications.

Machinery and Equipment Manufacturing

Many machine parts, such as shafts, bushings, and fasteners, are made from 1020 steel. The material’s ability to undergo various forming and machining processes ensures high efficiency in production.

Agricultural Equipment

1020 steel is also used in producing agricultural tools and machinery, such as plows, harrows, and support structures. Its durability and resistance to wear make it ideal for use in farming environments.

Benefits of Using 1020 Steel

There are several advantages to choosing 1020 steel for industrial applications:

- Excellent Weldability: It can be welded easily without requiring complex procedures.

- Good Machinability: The steel can be cut and shaped with minimal tool wear.

- High Ductility: Allows for easy forming and bending into different shapes.

- Cost-Effective: Compared to high-carbon or alloy steels, 1020 steel is relatively inexpensive.

- Versatile Applications: Suitable for automotive, construction, and machinery industries.

Conclusion

What Is 1020 Steel? 1020 steel is a versatile and widely used material due to its excellent mechanical properties and ease of processing. With its combination of strength, ductility, and affordability, what is 1020 steel serves as a crucial component in numerous industrial applications. Understanding what is 1020 steel and its characteristics can help manufacturers and engineers make informed decisions about its use in their projects.

FAQ

What is the difference between 1020 steel and other carbon steels?

1020 steel has a lower carbon content compared to higher-grade carbon steels such as 1045 steel. This results in increased ductility and better weldability but lower hardness and tensile strength.

Can 1020 steel be heat-treated?

Yes, 1020 steel can undergo heat treatment processes such as carburizing to improve its surface hardness. However, it does not respond well to standard hardening methods like quenching and tempering due to its low carbon content.

Is 1020 steel suitable for high-stress applications?

While 1020 steel is strong and durable, it is not ideal for high-stress applications where higher-strength alloys or hardened steels are required. It is best used in moderate-load-bearing components.

How does 1020 steel compare to stainless steel?

Unlike stainless steel, 1020 steel lacks significant corrosion resistance. It requires protective coatings or treatments to prevent rust and degradation when exposed to moisture and harsh environments.

What are the best processing methods for 1020 steel?

1020 steel can be easily machined, welded, and cold-formed. These processes make it an excellent choice for applications requiring precision shaping and structural integrity.