What Is 4140 Steel? 8 Crucial Insights

Table of Contents

Introduction

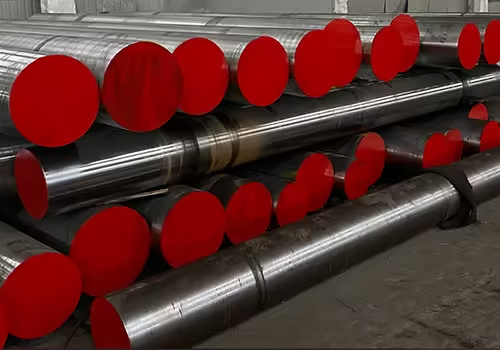

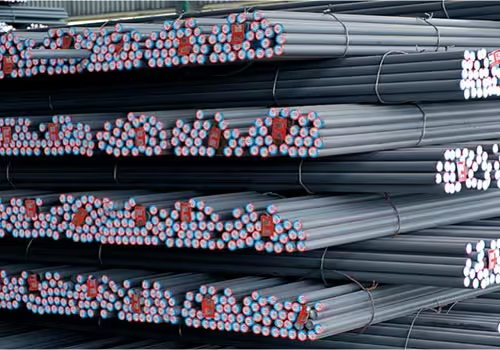

When exploring materials for industrial, mechanical, or engineering applications, one might ask: what is 4140 steel and why is it so widely used? What is 4140 steel, exactly? 4140 steel is a chromium-molybdenum alloy steel that offers a balance of strength, hardness, and toughness, making it ideal for a variety of demanding applications. This alloy falls under the category of medium-carbon steels, and its performance characteristics make it a top choice in sectors like automotive, manufacturing, oil and gas, and even aerospace.

Understanding what is 4140 steel is crucial for selecting the appropriate material for machinery components, shafts, bolts, gears, and other high-stress environments. By exploring what is 4140 steel, you’ll uncover why it’s such a versatile material with high strength and durability. Throughout this article, we will provide eight crucial insights to help you understand what is 4140 steel, its composition, properties, benefits, and real-world applications.

The Chemical Composition and Mechanical Properties of 4140 Steel

To truly grasp what is 4140 steel, we must begin by analyzing its chemical makeup and the mechanical properties it imparts. 4140 steel is classified as a chromium-molybdenum alloy steel, commonly referred to as a low-alloy steel. It stands out for its balanced blend of strength, toughness, and versatility.

Here is the typical chemical composition of 4140 steel:

| Element | Content (%) | Function |

|---|---|---|

| Carbon | 0.38 – 0.43 | Provides hardness and strength through heat treatment |

| Chromium | 0.80 – 1.10 | Enhances hardness, wear resistance, and corrosion resistance |

| Manganese | 0.75 – 1.00 | Improves hardenability and tensile strength |

| Molybdenum | 0.15 – 0.25 | Adds toughness and enhances high-temperature strength |

| Silicon | 0.15 – 0.30 | Promotes deoxidation and improves toughness |

| Iron (Fe) | Balance | The base element of the steel alloy |

These alloying elements work synergistically to create a material with excellent mechanical performance. Below are the typical mechanical properties of 4140 steel, especially in its annealed or normalized condition:

- Tensile Strength: 655 – 1080 MPa

- Yield Strength: 415 – 930 MPa

- Elongation: Approximately 25% in 2 inches (annealed)

- Hardness (Brinell): Around 197 HB (in annealed state)

These values can vary depending on the specific heat treatment applied, which is one of the most valuable attributes when discussing what is 4140 steel.

4140 steel responds very well to a range of heat treatments, including annealing, quenching, and tempering. This makes it highly customizable, allowing manufacturers to adjust its hardness and strength based on the desired application—whether that means making it tougher, softer, or more resilient.

Key Advantages of 4140 Steel for Industrial Applications

Understanding what is 4140 steel requires exploring why it is so widely used in demanding industrial settings. Its unique blend of chemical and mechanical characteristics delivers multiple advantages, especially for engineers and fabricators looking for performance-driven materials.

Strength and Durability

One of the key selling points of 4140 steel is its high strength. With its superior tensile and yield strength, it can withstand immense mechanical loads without deformation. This makes it particularly useful in structural and mechanical applications where stability and load-bearing capacity are paramount.

For example, in automotive and aerospace sectors, where parts endure extreme forces and vibrations, the robust structure of 4140 steel ensures long-term reliability.

Toughness and Ductility

A common misconception is that high-strength materials are inherently brittle. However, 4140 defies this assumption. The steel maintains excellent toughness—meaning it can absorb energy without cracking or failing. It also offers good ductility, allowing it to deform slightly before breaking.

This balance of toughness and strength is one of the reasons it’s so valuable in impact-prone environments, such as hammer tools, crankshafts, or drill rods.

Wear and Fatigue Resistance

Another essential point when examining what is 4140 steel is its resistance to wear and fatigue. Thanks to the presence of chromium and molybdenum, 4140 can resist surface wear, abrasion, and cyclic stress. This is especially useful in moving components, such as gears, axles, and shafts, which undergo constant friction and pressure.

Its fatigue resistance enhances the service life of parts, minimizing the need for frequent replacements and downtime—an essential factor in high-efficiency industries.

Machinability

Despite its strength, 4140 steel remains relatively machinable, especially when it is in the annealed condition. This characteristic is important in precision engineering, where shaping, drilling, or threading components must be performed with minimal difficulty.

Machinists and fabricators appreciate that it responds well to CNC machining, grinding, and polishing, making it a highly workable material even for complex parts.

Heat Treatment Flexibility

One of the standout features of 4140 is its exceptional heat treatment adaptability. It can be through-hardened, surface-hardened, tempered, or normalized, depending on what the final application requires. This enables manufacturers to customize the hardness, strength, and toughness based on different mechanical environments.

Its consistency in performance after heat treatment is why industries often rely on it for safety-critical components.

Common Applications That Show What Is 4140 Steel Used For

If you’re still wondering what is 4140 steel used for, the answer lies in its versatility. It is found across many industries, including:

- Automotive: Crankshafts, axle shafts, and gears

- Oil and Gas: Drill collars, mud motor shafts

- Manufacturing: Dies, fixtures, tool holders

- Construction: Bolts, studs, structural components

- Aerospace: Landing gear components and support parts

Comparison Table of 4140 Steel With Other Alloy Steels

The table below compares what is 4140 steel against other commonly used steels to highlight its unique advantages:

| Property | 4140 Steel | 1045 Steel | 4340 Steel | D2 Tool Steel |

|---|---|---|---|---|

| Carbon Content (%) | 0.38 – 0.43 | 0.43 – 0.50 | 0.38 – 0.43 | 1.50 – 1.60 |

| Hardness (Brinell) | ~197 (annealed) | ~163 | ~217 | ~255 |

| Tensile Strength (MPa) | 655 – 1080 | 570 – 700 | 745 – 1860 | 1900+ |

| Yield Strength (MPa) | 415 – 930 | 330 – 410 | 470 – 1650 | 1600+ |

| Machinability | Moderate | High | Moderate | Low |

| Heat Treatability | Excellent | Moderate | Excellent | Good |

This table provides a clear visual of what is 4140 steel in comparison to alternatives, emphasizing its well-rounded properties.

Heat Treatment Processes and Effects on 4140 Steel

What is 4140 steel in terms of heat treatment potential? This alloy is exceptionally versatile due to its balanced chemical composition, particularly its chromium and molybdenum content. These elements enhance its hardenability and responsiveness to thermal processing. Below are the main heat treatment processes used for 4140 steel and their specific effects:

Annealing

Annealing is a process where the steel is heated to a specific temperature (typically around 845°C to 870°C or 1550°F to 1600°F), held for a period of time, and then allowed to cool slowly, often in a furnace.

Purpose: To relieve internal stresses and improve machinability.

Effect: The steel becomes softer and more ductile, making it easier to cut, drill, or shape. It also enhances dimensional stability by reducing the tendency for distortion.

Application: Often used as a pre-treatment before machining or further heat treatment.

Normalizing

Normalizing involves heating the steel to approximately 870°C to 925°C (1600°F to 1700°F), followed by air cooling. This process is faster than annealing and used when a more uniform grain structure is needed.

Purpose: To refine grain size, improve mechanical uniformity, and enhance toughness.

Effect: Increases yield and tensile strength slightly compared to annealed steel, but with improved dimensional consistency.

Application: Frequently used for components that need consistent performance under moderate stress.

Hardening and Tempering

Hardening is typically done by heating the steel to around 845°C to 870°C (1550°F to 1600°F) and then quenching in oil. This is followed by tempering—reheating the steel to a lower temperature (typically 200°C to 600°C or 390°F to 1100°F) to reduce brittleness.

Purpose: To significantly increase hardness and strength while maintaining adequate toughness.

Effect: After tempering, 4140 steel achieves a desirable balance between strength and ductility. The resulting hardness can exceed 50 HRC depending on the tempering temperature.

Application: Ideal for shafts, gears, and wear-prone mechanical parts.

Nitriding

Nitriding is a surface hardening process that introduces nitrogen into the outer layer of the steel at temperatures between 500°C to 550°C (930°F to 1020°F).

Purpose: To create a hard, wear-resistant outer layer without altering the core’s toughness.

Effect: Improves surface hardness up to 1000 HV (Vickers hardness) while minimizing dimensional distortion, unlike traditional quenching.

Application: Common in aerospace, tooling, and high-precision manufacturing where both surface durability and dimensional accuracy are critical.

These treatments help engineers and metallurgists tailor what is 4140 steel into forms suitable for a wide range of demanding industrial applications. Whether the goal is extreme toughness, surface wear resistance, or dimensional stability, proper heat treatment enables 4140 steel to adapt effectively.

Limitations and Considerations When Using 4140 Steel

Though highly capable, what is 4140 steel’s downside? Some limitations include:

- Corrosion Resistance: Not suitable for corrosive environments unless coated or plated.

- Weldability: Requires preheat and post-heat processes to prevent cracking.

- Cost: Higher cost than plain carbon steels due to alloying elements and processing.

However, these are often mitigated with proper engineering techniques and material handling protocols.

Conclusion

To conclude, the question of what is 4140 steel reveals more than just a material specification. It’s a high-performance alloy that brings together strength, toughness, wear resistance, and machinability. Whether used in high-impact mechanical environments or precision-engineered aerospace parts, 4140 steel is trusted for its versatility and durability. Understanding its properties allows engineers and manufacturers to make informed choices that enhance performance and reduce costs over time.

FAQ

Is 4140 steel stainless steel?

No, 4140 is a low-alloy steel, not stainless steel. It contains some chromium but not enough for stainless steel classification.

Can 4140 steel be welded?

Yes, but it requires preheating and post-weld heat treatment to prevent cracking due to its high hardenability.

What heat treatments can be applied to 4140 steel?

4140 can undergo annealing, quenching, tempering, and normalizing, depending on the required mechanical properties.

How does 4140 compare to 1045 steel?

4140 is stronger and more hardenable than 1045, with better fatigue resistance due to alloying elements.

Is 4140 suitable for high-temperature applications?

Yes, it maintains strength at elevated temperatures but isn’t ideal for extreme heat like high-speed tool steels.

What are the machining characteristics of 4140?

In the annealed state, 4140 is easy to machine, but after hardening, specialized tools are recommended.