Why Experts Love AISI 4140 Steel in 2025

Table of Contents

Introduction

In recent years, the global demand for reliable and high-performance alloys has surged, particularly in sectors like automotive, aerospace, and heavy machinery. AISI 4140 steel, a low alloy steel containing chromium, molybdenum, and manganese, has emerged as a preferred material due to its excellent mechanical properties and versatility. Its strength, hardness, fatigue resistance, and ability to be heat-treated have made it a favorite among industry experts. In 2025, its popularity continues to grow as more manufacturers and engineers turn to this trusted alloy for critical applications.

This blog explores why professionals across various sectors regard AISI 4140 steel so highly, highlighting its key features, benefits, and typical applications, while also comparing it with other commonly used steels.

What Makes AISI 4140 Steel Stand Out in 2025?

This alloy continues to shine in 2025 thanks to a combination of mechanical strength, toughness, and adaptability that aligns with the evolving demands of modern engineering and production. Its reliability across industries has solidified its reputation as a top-tier material solution.

High Strength and Toughness

One of the defining characteristics of this material is its high tensile strength, typically ranging from 655 to 1080 MPa depending on the heat treatment applied. This strength makes it an excellent candidate for components exposed to heavy mechanical loads and impacts, such as automotive drive shafts and structural fasteners. Its toughness further contributes to its performance under harsh conditions, providing the resilience required in sectors like construction and oil drilling.

Excellent Hardening Capability

Another standout attribute is its excellent responsiveness to thermal treatment. The alloy can be effectively hardened through oil quenching, achieving hardness levels of approximately 28–32 HRC in a normalized state, with potential for even greater hardness after advanced treatment. This flexibility in heat treatment allows engineers to customize the material for specific use cases, striking a balance between hardness and ductility as needed.

Good Fatigue and Wear Resistance

Durability under repeated mechanical stress is critical in many applications, especially where parts are subjected to rotational or cyclic forces. Gears, axles, and bolts made from this alloy exhibit exceptional fatigue life. The material also maintains its integrity in high-friction environments, reducing the frequency of part replacement and minimizing equipment downtime, which translates into substantial cost savings over time.

Versatility in Applications

What sets this alloy apart is its adaptability across a wide spectrum of industries. Whether it’s die manufacturing, tooling, or high-load machinery, this material meets the requirements of each with consistent performance. Its presence is commonly found in crankshafts, drill collars, and other high-stress components. In 2025, this flexibility continues to fuel its demand among professionals who prioritize dependability and material longevity.

Chemical and Mechanical Properties of AISI 4140 Steel

Understanding the alloy’s properties helps clarify why it is favored in 2025. Below is a detailed comparison table illustrating both chemical composition and mechanical performance.

Table: AISI 4140 Steel – Chemical and Mechanical Properties

| Property | Specification Range |

|---|---|

| Carbon (C) | 0.38 – 0.43% |

| Manganese (Mn) | 0.75 – 1.00% |

| Chromium (Cr) | 0.80 – 1.10% |

| Molybdenum (Mo) | 0.15 – 0.25% |

| Tensile Strength | 655 – 1080 MPa |

| Yield Strength | 415 – 930 MPa |

| Elongation | 20 – 25% |

| Hardness (Brinell) | 197 – 269 HB |

| Impact Toughness | High, varies with treatment |

These properties confirm that AISI 4140 steel offers a solid balance of strength, toughness, and wear resistance—an ideal combination for heavy-duty environments.

Key Applications Driving the Demand for AISI 4140 Steel

The widespread use of this chromium-molybdenum alloy across critical sectors underscores its unmatched versatility and reliability in modern engineering. From high-speed vehicles to massive construction machinery, its robust characteristics make it indispensable in numerous high-stakes environments.

Automotive and Transportation

In the rapidly evolving automotive sector, manufacturers are turning to this advanced material for the production of essential drivetrain and suspension components. Items such as axles, transmission gears, and crankshafts benefit from the alloy’s impressive fatigue strength and toughness. These properties enable vehicles to endure prolonged mechanical stress, making them more durable and efficient over time. Its ability to undergo heat treatment also allows for fine-tuning performance according to specific application demands.

Aerospace Engineering

Aircraft construction demands materials that can endure both high stress and wide temperature fluctuations. This alloy meets those requirements by offering outstanding mechanical resilience and thermal stability. Components like landing gear assemblies, engine brackets, and various structural connectors utilize the material’s strength-to-weight ratio to ensure safety and performance in flight. Its stability under dynamic loading conditions makes it especially suitable for aerospace frameworks that must meet stringent regulatory standards.

Oil and Gas Industry

Exploration and extraction in the energy sector expose tools to extreme pressure, abrasion, and chemically aggressive environments. For these challenges, engineers commonly deploy this medium-carbon alloy in applications like downhole drilling tools, threaded connectors, and stabilizer collars. Its wear resistance and hardness ensure extended operational life, reducing downtime and maintenance frequency—a major cost advantage in offshore and onshore drilling projects.

Heavy Equipment Manufacturing

The construction and mining industries require machinery capable of handling substantial loads and harsh operational conditions. Earthmoving equipment, cranes, and hydraulic systems often include rods, pins, and shafts fabricated from this durable alloy. Its resistance to impact and mechanical wear ensures that even under continuous stress, the components maintain structural integrity, reducing the likelihood of unexpected failures.

Tool and Die Production

Precision and durability are paramount in toolmaking. This engineering material is a top choice for producing jigs, fixtures, dies, and molds used in metal stamping, forging, and plastic injection molding. Its capacity to retain dimensional stability after repeated use—and its compatibility with surface hardening processes—allows for extended tool life without compromising accuracy or performance. As a result, manufacturers can rely on consistent quality in mass production environments.

How AISI 4140 Steel Compares to Other Popular Steels

Selecting the appropriate steel grade for a specific application requires a comprehensive understanding of how various alloys stack up against each other in terms of mechanical properties, heat treatment capabilities, and intended use cases. The chromium-molybdenum composition of this medium-carbon alloy gives it a unique blend of strength, toughness, and wear resistance, setting it apart from several widely used steels.

Versus AISI 1045: Strength and Hardenability Take the Lead

AISI 1045 is a medium carbon steel commonly chosen for general-purpose applications due to its decent machinability and moderate strength. However, when compared to the 4140 grade, 1045 falls short in several performance aspects. Most notably, it lacks the alloying elements—chromium and molybdenum—that enhance the latter’s hardenability and toughness.

While 1045 is suitable for components like shafts, bolts, and rods used in less demanding environments, it doesn’t perform as well under high fatigue or impact stress. In contrast, the stronger alloy can be quenched and tempered to achieve higher tensile strength, making it ideal for more severe service conditions such as those encountered in automotive drivetrains, heavy machinery, or high-stress tooling.

Versus A36: Structural Simplicity vs. Engineering Performance

A36 is a low-carbon structural steel primarily chosen for its ease of fabrication and excellent weldability. It is widely used in construction, bridges, and general structural frameworks. However, its mechanical strength is relatively low, and it cannot be heat-treated to significantly improve hardness or tensile performance.

For applications requiring resistance to dynamic or cyclic loading, such as mechanical power transmission components or tooling fixtures, A36 simply doesn’t offer the reliability or durability that the alloyed steel provides. The latter’s superior yield strength and wear resistance make it more suitable for use cases where longevity and mechanical integrity are crucial, even under extreme operational demands.

Versus Stainless Steels: Strength vs. Corrosion Resistance

Stainless steel grades, such as 304 or 316, are often the go-to choice for environments where corrosion is a significant concern—such as in food processing, marine, or chemical exposure scenarios. These steels excel in resisting rust and oxidation, but they often do so at the expense of mechanical performance, especially in terms of tensile and yield strength.

Compared to these corrosion-resistant alloys, the molybdenum-enhanced material delivers much higher strength and hardness. This makes it the preferred option for applications like gears, axles, and high-load machinery components, where structural performance outweighs environmental exposure concerns. That said, the choice between these materials often hinges on the specific service environment: if corrosion is minimal and mechanical demands are high, the tougher alloy is generally the superior option.

Heat Treatment Techniques and Machinability

One reason experts love AISI 4140 steel in 2025 is its adaptability to various heat treatment techniques, which fine-tune its performance to match specific operational needs.

Common Heat Treatment Methods

- Annealing: Enhances machinability

- Normalizing: Improves uniformity in structure

- Quenching and Tempering: Increases hardness and tensile strength

These methods allow engineers to customize the steel’s properties for optimal performance in demanding tasks.

Machinability

Though not as easy to machine as free-cutting steels, AISI 4140 steel performs well with proper tools and cutting fluids, especially in normalized or annealed conditions.

Experts’ Perspective: Why AISI 4140 Steel Remains a Go-To Material

Industry experts continuously favor AISI 4140 steel because of its proven track record. It offers:

- Cost-effective performance

- Excellent balance of strength and ductility

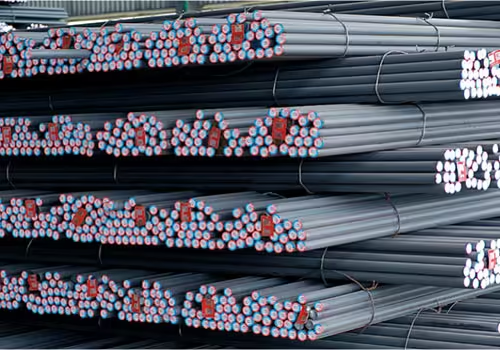

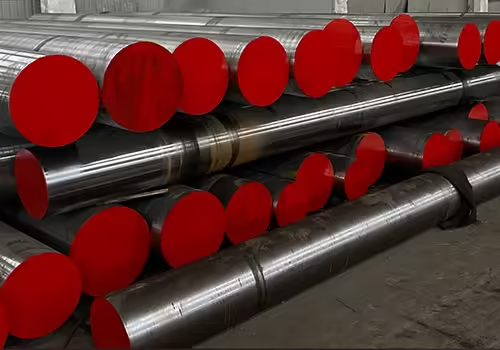

- Wide availability in various forms (round bar, sheet, forged blocks)

Its consistency and adaptability make it a low-risk, high-reward option for designers and engineers alike.

Conclusion

In 2025, the popularity of AISI 4140 steel shows no signs of slowing down. With its excellent mechanical properties, wide-ranging applications, and compatibility with modern heat treatment techniques, it remains a top choice among materials engineers and manufacturing professionals.

As industries evolve toward more efficient and durable solutions, AISI 4140 steel continues to meet the challenges of modern engineering. Its presence in critical industries ensures that it will remain a foundational material well into the future.

FAQ

What is the difference between AISI 4140 steel and AISI 4130?

AISI 4140 steel contains higher carbon and chromium content, offering greater hardness and strength compared to AISI 4130.

Can AISI 4140 steel be welded?

Yes, but it requires preheating and post-weld heat treatment to avoid cracking due to its high hardenability.

Is AISI 4140 steel corrosion-resistant?

It has moderate corrosion resistance but is not as resistant as stainless steel. Protective coatings or surface treatments are recommended for corrosive environments.

What are the common forms of AISI 4140 steel available in the market?

It is commonly available in bars, rods, sheets, and forged components.

Is AISI 4140 steel suitable for cold forming?

While possible, cold forming is limited due to the alloy’s hardness. Hot forming or machining is generally preferred.

What makes AISI 4140 steel a favorite for automotive applications?

Its excellent fatigue resistance, strength, and heat treatability make it ideal for components like gears, axles, and crankshafts.

How should AISI 4140 steel be stored?

It should be kept in a dry environment and coated with rust inhibitors if not used immediately, to prevent oxidation.

Does AISI 4140 steel support surface hardening?

Yes, it can be surface hardened using techniques like induction hardening, which enhances wear resistance while retaining core toughness.

Can it be used at high temperatures?

AISI 4140 steel maintains its mechanical properties well up to 500°C, making it suitable for moderately high-temperature applications.

How sustainable is AISI 4140 steel in modern manufacturing?

Thanks to its long service life and recyclability, it is considered a sustainable material choice for a wide range of applications.