Will Steel Rust Faster in Coastal Areas? Factors to Consider

Table of Contents

Introduction

When it comes to steel and its long-term durability, rust is one of the most significant concerns, especially in environments exposed to moisture. One of the most common questions that arise in industries ranging from construction to manufacturing is: will steel rust faster in coastal areas? The answer isn’t as straightforward as it may seem, as there are various factors that influence how quickly steel will corrode in these regions.

In this article, we will explore the various conditions that impact how steel behaves in coastal areas, why it rusts faster in such environments, and what preventive measures can be taken. Understanding these factors will help you make informed decisions regarding material selection and protective coatings in coastal or marine settings.

Why Does Steel Rust?

Before diving into the specifics of corrosion in coastal areas, it’s essential to first understand why steel rusts in the first place. At its core, rust is a product of a chemical reaction called oxidation. This process occurs when iron (the main component of steel) reacts with oxygen from the air and moisture (water or humidity) to form iron oxide, commonly known as rust.

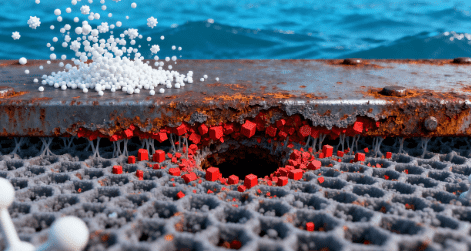

Rusting is essentially an electrochemical process that involves the transfer of electrons between the steel and the surrounding environment. This chemical reaction creates a reddish-brown flaky substance that not only damages the aesthetic quality of steel but also compromises its strength, durability, and overall integrity.

The Rusting Process (Oxidation)

Here’s a simplified breakdown of the oxidation process:

- Electrochemical Reaction: When steel is exposed to oxygen and water, the surface of the steel begins to lose electrons. This process is known as oxidation.

- Formation of Iron Oxide: As the iron loses electrons, it combines with oxygen to form iron oxide, commonly known as rust.

- Spread of Corrosion: The rust itself is porous and cannot protect the steel from further oxidation, which leads to the continuous breakdown of the material. Over time, the steel weakens and may eventually fail if the corrosion is extensive.

The rate at which steel rusts depends on various factors, such as moisture availability, environmental pollutants, and temperature fluctuations. Steel does not rust uniformly everywhere — it rusts faster in certain conditions, especially in coastal areas.

Will Steel Rust Faster in Coastal Areas?

Coastal Areas and Saltwater Exposure

One of the most significant contributors to the accelerated rusting of steel in coastal regions is saltwater exposure. Coastal environments naturally feature saltwater, which contains high concentrations of dissolved salts, particularly sodium chloride (NaCl). When steel is exposed to saltwater, the corrosion process speeds up for several reasons:

- Increased Conductivity: Saltwater is a better conductor of electricity than freshwater, which means it accelerates the electrochemical reactions that cause corrosion. In simple terms, saltwater allows for the easier flow of electrons from the steel, which enhances the oxidation process.

- Moisture Retention: Saltwater also retains moisture more effectively than fresh water, and moisture is a key element in the corrosion process. Salt molecules attract water, creating a more humid environment around the steel surface. This increased moisture exposure further fuels the corrosion reaction.

- Salt Spray and Mist: Coastal winds can carry tiny droplets of saltwater that form a fine mist, which is known as salt spray. Even if steel structures are not submerged in seawater, they are constantly exposed to this salt-laden air, which accelerates rusting. This phenomenon is common in coastal construction, shipbuilding, and offshore structures.

Thus, steel exposed to coastal conditions will often experience faster rusting than steel in areas where there is less salt or moisture in the air.

High Humidity in Coastal Regions

Coastal regions are characterized by high humidity levels. Humidity is the amount of water vapor in the air, and coastal areas typically experience much higher levels of humidity compared to inland locations. When steel is exposed to humid air, moisture in the air condenses on the surface of the metal, promoting the corrosion process.

- Humidity and Corrosion: High humidity levels mean that there is more moisture in the environment, and this moisture interacts with the steel surface, creating the ideal conditions for rust to form. In fact, steel in high-humidity environments tends to form a thin layer of rust much faster than it would in dry conditions.

- Condensation Formation: Coastal areas experience daily temperature fluctuations, and the combination of moist air and fluctuating temperatures can cause condensation to form on steel surfaces, especially at night when the air cools. This condensation, often unnoticed, is a hidden threat to the longevity of steel structures. Condensation creates a moist environment on steel surfaces, contributing to faster corrosion.

Temperature Variations and Corrosion

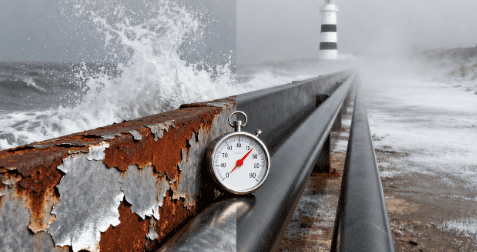

Temperature changes also play a significant role in accelerating steel rusting in coastal environments. Coastal areas are known for their extreme temperature fluctuations, particularly between day and night or across different seasons. These fluctuations can result in several outcomes:

- Condensation Formation: During the night or early morning, cooler temperatures cause the moisture in the air to condense on steel surfaces, which essentially creates water droplets on the metal. These droplets then facilitate the oxidation process, leading to rust formation. This effect is especially noticeable in the early morning, when the difference between day and night temperatures can be significant.

- Thermal Expansion: Steel expands and contracts with temperature changes. During the day, as temperatures rise, steel expands, and at night, as temperatures fall, the metal contracts. This movement can cause cracks or fissures to form in coatings or protective layers on the steel, exposing the metal to moisture and further corrosion.

- Seasonal Corrosion Risks: In coastal areas, the change from warm to cold seasons can increase the likelihood of frost or dew forming on steel surfaces. These environmental conditions provide constant moisture, especially during winter, which exacerbates the rusting process.

Factors That Affect How Fast Steel Rusts in Coastal Areas

Several factors come into play when determining how quickly steel will rust in coastal areas. While saltwater and humidity are significant contributors, there are other considerations that can influence the rate of corrosion:

Type of Steel

Not all types of steel are equally susceptible to rust. Steel alloys that include higher amounts of chromium, such as stainless steel, are more resistant to corrosion because the chromium forms a passive layer on the steel’s surface that protects it from moisture and salt. In contrast, carbon steel lacks this protective layer and is more prone to rust, especially in coastal areas.

Protective Coatings

The presence of protective coatings can greatly influence the rate of rusting. Steel that is coated with galvanization, a process that involves coating the steel with a layer of zinc, is far less susceptible to rust. The zinc protects the steel from moisture and saltwater exposure, as it corrodes before the steel itself, serving as a sacrificial layer. However, even galvanized steel can eventually rust if the zinc coating is damaged.

Maintenance Practices

Steel structures that are regularly maintained and cleaned are less likely to rust than those that are neglected. For example, periodic washing to remove salt buildup, as well as timely touch-ups on damaged coatings, can significantly reduce the likelihood of rusting. Proper maintenance ensures that steel stays protected from environmental elements, including saltwater and humidity.

Presence of Airborne Salt

In coastal areas, airborne salt particles can settle on steel surfaces, accelerating the corrosion process even if the steel is not in direct contact with water. This phenomenon is especially prominent in areas with strong winds or coastal storms, which can propel salt further inland.

Factors Influencing Steel Rusting in Coastal Areas

| Factor | Impact on Corrosion | Possible Solutions |

|---|---|---|

| Saltwater Exposure | Accelerates corrosion through electrochemical reactions. | Use of corrosion-resistant alloys, coatings like galvanization. |

| High Humidity | Increases moisture exposure, facilitating rust formation. | Install dehumidifiers or moisture barriers. |

| Temperature Fluctuations | Condensation from temperature changes can promote rust. | Use insulated coatings or temperature-resistant materials. |

| Type of Steel | Stainless steel resists corrosion better than carbon steel. | Opt for stainless steel or high-alloy steels for coastal applications. |

| Protective Coatings | Coatings like zinc protect steel from direct exposure. | Regular maintenance of coatings to prevent rust. |

| Airborne Salt | Salt carried by the wind accelerates corrosion. | Regular cleaning and coating protection. |

Preventive Measures for Steel in Coastal Areas

Galvanization and Coatings

One of the most effective ways to prevent steel from rusting in coastal areas is to apply a protective coating such as galvanization. This process involves coating steel with a thin layer of zinc, which acts as a sacrificial anode, preventing the steel underneath from corroding. Other protective coatings, such as epoxy, polyurethane, or powder coatings, can also offer additional protection against saltwater and humidity.

Stainless Steel

For critical applications where rust resistance is essential, using stainless steel is an excellent choice. Stainless steel contains a higher percentage of chromium, which forms a protective oxide layer on the surface of the metal. This layer prevents moisture and air from reacting with the iron in the steel, significantly reducing the likelihood of rust.

Regular Maintenance

Regular maintenance practices such as cleaning, inspecting, and touching up protective coatings can prevent the accumulation of salt and moisture on steel surfaces. This is especially important in coastal regions, where salt from the sea can be carried by the wind and deposited on steel structures. By maintaining these surfaces, you can prolong the life of steel and minimize corrosion.

Conclusion

In conclusion, steel does rust faster in coastal areas due to the combined effects of saltwater exposure, high humidity, and temperature fluctuations. However, the rate at which steel rusts can vary depending on several factors, such as the type of steel used, protective coatings, and maintenance practices.

By choosing the right materials, applying protective coatings, and regularly maintaining steel structures, it’s possible to extend the lifespan of steel in coastal environments and reduce the risk of rusting. Whether you’re designing a building, infrastructure, or equipment for coastal areas, understanding the factors that influence corrosion will allow you to make informed decisions that improve the longevity and safety of your steel structures.

FAQ

Does steel rust in saltwater?

Yes, steel rusts faster in saltwater due to the high salt content, which accelerates the electrochemical reaction that causes rust.

Can galvanization prevent rust on steel in coastal areas?

Yes, galvanization significantly reduces the risk of rust by coating steel with a layer of zinc, which protects the underlying steel from exposure to moisture and salt.

What is the best type of steel to use in coastal environments?

Stainless steel is the best choice for coastal environments due to its resistance to corrosion and its ability to withstand exposure to saltwater and humidity.

How often should steel structures be maintained in coastal areas?

Steel structures in coastal areas should be regularly cleaned and inspected, with any protective coatings maintained or reapplied as needed to prevent rust.