10 Amazing 42crmo4 Steel Mechanical Properties Explained

Table of Contents

Introduction

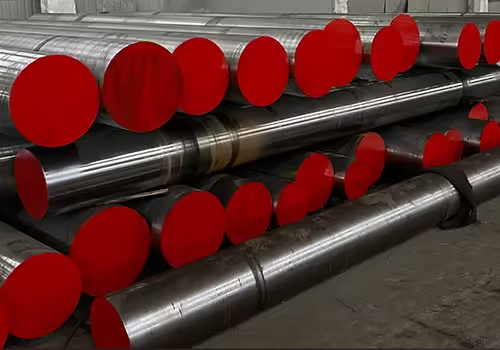

When it comes to choosing high-performance steel for engineering and industrial applications, 42crmo4 steel is one of the most reliable options available. Known for its exceptional strength, toughness, and wear resistance, this alloy steel has been widely used in the manufacturing of critical mechanical components. Understanding the 42crmo4 steel mechanical properties is crucial for engineers, designers, and procurement specialists who want to ensure optimal performance and longevity of their products.

42crmo4 steel, also known by its equivalent grades like AISI 4140 or EN 42CrMo4, is a chromium-molybdenum alloy steel that offers a balanced combination of toughness, hardness, and fatigue resistance. This balance makes it ideal for parts subjected to high stresses and dynamic loading. This blog explores 10 amazing aspects of 42crmo4 steel mechanical properties that make it a popular choice in various industries.

The Chemical Composition Influencing 42crmo4 Steel Mechanical Properties

The unique mechanical properties of 42crmo4 steel are directly related to its carefully controlled chemical composition. The steel typically contains carbon (about 0.38-0.45%), chromium (0.9-1.2%), molybdenum (0.15-0.3%), manganese (0.6-0.9%), silicon (0.15-0.4%), and traces of sulfur and phosphorus.

These alloying elements significantly affect the mechanical behavior of the steel. Carbon increases hardness and strength but reduces ductility when present in high amounts. Chromium enhances corrosion resistance and hardness, molybdenum contributes to toughness and high-temperature strength, while manganese and silicon improve tensile strength and deoxidation respectively.

The combination of these elements in 42crmo4 steel mechanical properties allows it to maintain good wear resistance while preserving the ductility and toughness needed for impact resistance. This alloy steel’s balanced chemistry helps it perform reliably in demanding mechanical environments.

Key Mechanical Properties of 42crmo4 Steel

To fully appreciate the value of 42crmo4 steel in engineering applications, it is essential to examine its main mechanical properties:

- Tensile strength

- Yield strength

- Elongation

- Hardness

- Impact toughness

- Fatigue strength

- Modulus of elasticity

These mechanical characteristics define how the material behaves under various mechanical loads and conditions.

Tensile Strength and Yield Strength

The tensile strength of 42crmo4 steel typically ranges from 850 to 1100 MPa, although the exact value largely depends on the specific heat treatment process applied. This impressive tensile strength means that the steel can endure substantial pulling or stretching forces before breaking. It makes 42crmo4 steel particularly suitable for structural parts and mechanical components that experience high stress during operation.

Yield strength, on the other hand, is generally between 600 and 900 MPa. This parameter is crucial because it defines the stress level at which the steel will begin to deform permanently — that is, it won’t return to its original shape after the force is removed. A high yield strength means that 42crmo4 steel parts can handle greater loads without suffering irreversible deformation, which is vital in applications where dimensional stability and precision are required.

These strength parameters also influence how engineers design components to resist failure under dynamic loads or sudden impacts. For example, in automotive or heavy machinery, parts made from 42crmo4 steel can maintain integrity under intense forces, contributing to overall safety and durability.

Elongation and Ductility

Elongation is a measure of how much a material can stretch or lengthen before it breaks, and for 42crmo4 steel, elongation values typically fall within 12-16%. This moderate elongation indicates that the steel possesses a balanced ductility, which means it can absorb some deformation without cracking or fracturing.

Ductility is a critical property for components subjected to bending, twisting, or shock loads because it allows the material to deform plastically and absorb energy rather than fail abruptly. This quality reduces the risk of catastrophic failure in parts like shafts, gears, or fasteners that may experience sudden or fluctuating stresses during their service life.

Moreover, the elongation level in 42crmo4 steel can be influenced by heat treatment and alloying elements. Proper tempering after quenching can optimize ductility, striking a balance between strength and flexibility tailored to specific engineering requirements.

Hardness Levels

Hardness is a key factor affecting wear resistance and machinability. In its annealed state, 42crmo4 steel usually exhibits a Brinell hardness (HB) around 200 to 250, which means the steel is relatively soft and easy to machine or form. This is ideal during manufacturing processes when shaping or cutting the material.

However, once heat-treated — typically by quenching and tempering — the hardness can increase dramatically, reaching up to 55 HRC (Rockwell hardness). This hardened state significantly improves resistance to abrasion, surface wear, and deformation under load. Such hardness levels make 42crmo4 steel ideal for components like gears, crankshafts, and heavy-duty bolts, where surface durability is paramount.

The ability to control hardness through heat treatment allows manufacturers to customize the steel’s performance: softer for ease of fabrication, or harder for demanding operational environments. This versatility makes 42crmo4 steel a popular choice across many mechanical and industrial sectors.

Impact Toughness and Fatigue Strength

The alloy’s impact toughness is excellent, particularly after tempering, which allows it to absorb energy from sudden shocks without fracturing. Its fatigue strength also supports its use in components that undergo repeated cyclic loading, such as shafts and gears.

Modulus of Elasticity

The modulus of elasticity of 42crmo4 steel is around 210 GPa, a typical value for carbon steels, which indicates its stiffness or resistance to elastic deformation.

Table: Typical Mechanical Properties of 42crmo4 Steel

| Mechanical Property | Value Range | Test Standard | Notes |

|---|---|---|---|

| Tensile Strength (MPa) | 850 – 1100 | ASTM E8 / ISO 6892 | Depends on heat treatment |

| Yield Strength (MPa) | 600 – 900 | ASTM E8 / ISO 6892 | Offset 0.2% |

| Elongation (%) | 12 – 16 | ASTM E8 / ISO 6892 | Uniform elongation |

| Hardness (HB) | 200 – 250 (annealed) | ASTM E10 | Brinell hardness |

| Hardness (HRC) | 40 – 55 (quenched/tempered) | ASTM E18 | Rockwell hardness |

| Impact Toughness (J) | 30 – 60 | ASTM E23 | Charpy V-notch at room temp |

| Fatigue Strength (MPa) | ~370 | ASTM E466 | Endurance limit |

| Modulus of Elasticity (GPa) | ~210 | ASTM E111 | Elastic modulus |

This table summarizes the key mechanical data that engineers use to assess the suitability of 42crmo4 steel for various applications.

Applications Leveraging 42crmo4 Steel Mechanical Properties

The impressive mechanical properties of 42crmo4 steel make it a favorite in industries where durability and performance are critical. Common applications include:

- Automotive components such as crankshafts, gears, and axles

- Heavy machinery parts like shafts, pins, and bolts

- Aerospace components requiring high strength and fatigue resistance

- Construction equipment parts subjected to impact and wear

- Oil and gas industry equipment needing corrosion resistance and toughness

The versatility of 42crmo4 steel mechanical properties allows designers to optimize parts that must balance strength, toughness, and wear resistance.

Heat Treatment Effects on 42crmo4 Steel Mechanical Properties

Heat treatment processes such as annealing, quenching, and tempering are fundamental techniques that significantly influence and tailor the 42crmo4 steel mechanical properties to meet specific engineering requirements. Each heat treatment method affects the internal microstructure of the steel differently, thereby altering its mechanical behavior.

Annealing, for instance, involves heating the steel to a specific temperature and then cooling it slowly. This process softens the material, which greatly improves machinability and ease of forming but simultaneously reduces the overall strength and hardness. This modification of 42crmo4 steel mechanical properties makes annealed steel ideal for applications where complex machining or shaping is necessary before final hardening.

On the other hand, quenching followed by tempering is widely used to enhance the strength and hardness of 42crmo4 steel while maintaining a balanced level of toughness. Quenching rapidly cools the steel, locking in a hard but brittle microstructure, whereas tempering reheats the steel to a lower temperature to reduce brittleness and improve ductility. This heat treatment sequence optimizes the 42crmo4 steel mechanical properties, producing components capable of withstanding high stress and wear conditions.

By carefully controlling the parameters of heat treatment — including temperature, time, and cooling rate — manufacturers can precisely engineer the 42crmo4 steel mechanical properties to suit a wide range of demanding applications. For example, a highly tempered 42crmo4 steel gear will exhibit superior wear resistance and fatigue strength compared to untreated or only annealed counterparts. This ability to fine-tune 42crmo4 steel mechanical properties through heat treatment is essential in industries such as automotive, aerospace, and heavy machinery, where performance and durability are critical.

Conclusion

In summary, the 42crmo4 steel mechanical properties offer an exceptional combination of strength, toughness, hardness, and fatigue resistance that meets the demands of various heavy-duty applications. Engineers who understand these properties can select and specify the right material grades and treatments to maximize component performance and lifespan.

Choosing 42crmo4 steel is a smart decision when durability and reliability are essential. Its versatility, influenced by chemical composition and heat treatment, enables manufacturers to produce parts that excel under mechanical stress and dynamic loads.

FAQ

Q1: What makes 42crmo4 steel mechanical properties superior to other steels?

A1: Its balanced composition of chromium and molybdenum provides a unique combination of hardness, toughness, and corrosion resistance not typically found in standard carbon steels.

Q2: Can 42crmo4 steel mechanical properties be customized?

A2: Yes, heat treatment processes such as quenching and tempering allow manufacturers to adjust hardness, strength, and toughness to meet specific application requirements.

Q3: Is 42crmo4 steel suitable for high-temperature applications?

A3: While 42crmo4 steel offers good high-temperature strength, it is typically used within moderate temperature ranges; for extreme conditions, other alloys may be more appropriate.

Q4: How does the fatigue strength of 42crmo4 steel compare with other alloy steels?

A4: 42crmo4 steel exhibits excellent fatigue strength, making it well-suited for parts subjected to cyclic loads such as shafts and gears.

Q5: What industries benefit most from 42crmo4 steel mechanical properties?

A5: Automotive, aerospace, heavy machinery, construction, and oil & gas industries rely heavily on this steel due to its excellent mechanical balance.