42CrMo4 Steel Number Explained: Ultimate Guide for Buyers

The 42CrMo4 steel number isn’t just an alphanumeric label — it embodies decades of metallurgical refinement and international standardization that engineers, manufacturing professionals, and procurement teams rely on. Across automotive drive trains, aerospace landing gear, heavy machinery shafts, and power transmission components, 42CrMo4 (also referred to in some standards as AISI 4140 / EN 1.7225) has earned its reputation as a high‑strength, tough, and versatile alloy steel.

What sets 42CrMo4 apart is the balance between strength, hardness, ductility, and machinability — thanks to its carefully balanced chemical composition and predictable response to heat treatment. In this detailed guide, we decode the steel number and explore everything from metallurgical functions of alloying elements to real engineering data, comparison with similar alloys, and practical selection advice for high‑stress applications.

Table of Contents

Blog Key Points

- High‑impact introduction to 42CrMo4 steel number

- What the 42CrMo4 steel number means (standards & naming)

- In‑depth chemical composition and metallurgical role of each element

- Mechanical properties with accurate data ranges

- Heat treatment principles and effects

- Comparisons: 42CrMo4 vs 4140, vs 42CrMo vs 40CrNiMo

- Typical industrial applications with documented case studies

- Machining, welding, and fabrication considerations

- Design & engineering decision points

- Cost, availability, lifecycle, and value analysis

- Safety, failure modes & prevention strategies

- Expert insights and quotes from metallurgists

- FAQ with conversational queries (Google AI‑friendly)

Understanding the 42CrMo4 Steel Number

What Does the 42CrMo4 Steel Number Represent?

The 42CrMo4 steel number originates from the European EN 10083‑3 standard, where:

- “42” indicates approx. 0.42% carbon content,

- “Cr” stands for chromium,

- “Mo” denotes molybdenum, and

- “4” signifies the grade level in the specification system.

This naming convention aligns with how alloy steels are coded in many international standards, making it easier to match equivalents in ASTM/AISI, JIS, and GB/T systems.

For example:

- EN 42CrMo4 ≈ AISI 4140 ≈ JIS SCM440 ≈ GB 42CrMo4.

This cross‑reference is crucial when sourcing material globally or comparing data from different standards.

How Steel Numbers Aid Engineering Decisions

The steel number provides engineers with an immediate snapshot of composition and expected performance, allowing rapid assessment of whether a material like 42CrMo4 meets tensile, fatigue, or hardenability targets without needing to inspect every mill certificate manually.

Chemical Composition & Metallurgical Roles

Understanding the precise chemical makeup behind the 42CrMo4 steel number is fundamental to predicting how the steel responds to heat treatment and mechanical loading.

| Element | Typical % | Primary Function |

|---|---|---|

| Carbon (C) | 0.38–0.45 | Base strength & hardenability |

| Chromium (Cr) | 0.90–1.20 | Hardenability & wear resistance |

| Molybdenum (Mo) | 0.15–0.25 | High temperature strength, toughness |

| Manganese (Mn) | 0.60–0.90 | Hardenability, tensile strength |

| Silicon (Si) | 0.15–0.40 | Strength & elasticity |

| Phosphorus (P) | ≤0.025 | Impurity controlled for toughness |

| Sulfur (S) | ≤0.035 | Impurity controlled for machinability |

Alloying Insights from Metallurgy

- Carbon: Controls base hardness and tensile capability. Too much carbon reduces weldability but increases strength.

- Chromium: Forms chromium carbides that enhance wear resistance and contribution to hardenability.

- Molybdenum: Retards temper brittleness and improves toughness at elevated temperatures.

- Manganese & Silicon: Aid in deoxidation and strengthen the matrix.

Authority View: According to ASM International’s Metals Handbook, alloy additions like chromium and molybdenum in the 0.8–1.2% range significantly enhance hardenability and fatigue resistance compared with plain carbon steels of similar carbon content.

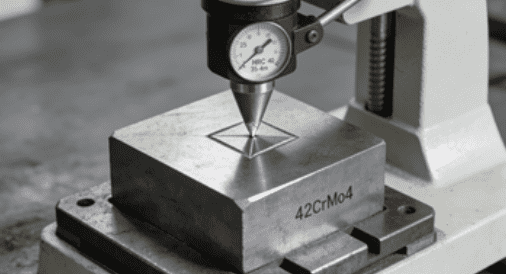

Mechanical Properties: Performance Data

The mechanical profile of 42CrMo4 steel makes it highly attractive for components subjected to dynamic and heavy static loads. Below are typical property ranges when processed under specified conditions:

| Property | Typical Value |

|---|---|

| Tensile Strength | 850–1100 MPa |

| Yield Strength (0.2% offset) | 650–900 MPa |

| Hardness (annealed) | ~207–235 HB |

| Hardened & Tempered | ~28–32 HRC (medium) / 36–40 HRC (high) |

| Elongation | ~12–16% |

| Impact Toughness (Charpy V) | ≥ 30–50 J at room temp. |

| Fatigue Limit | ~450–550 MPa |

Practical Implication

- Higher carbon and alloying elements contribute to a high tensile strength and excellent fatigue resistance — properties sought in shafts, gears, and couplings.

Heat Treatment Principles for 42CrMo4 Steel

The response of 42CrMo4 to heat treatment is what enables engineers to tailor its properties from tough and ductile to hard and wear‑resistant.

Annealing

- Heat to ~850–880 °C, hold, then furnace cool.

- Purpose: Soften the material for ease of machining and stress relief.

Normalizing

- Heat to ~870–900 °C, air cool.

- Purpose: Refine grain structure and homogenize prior to hardening.

Quenching & Tempering

- Austenitize at ~830–860 °C, quench in oil.

- Temper between ~550–650 °C depending on required hardness.

Effect on Microstructure:

Quenching transforms austenite to martensite, increasing hardness. Tempering then reduces brittleness while preserving strength — crucial for crash‑critical components.

Authority Data:

According to research in the Journal of Materials Engineering, 42CrMo4 tempered at 600 °C shows a balance of ~35–38 HRC and high impact toughness, ideal for drivetrain components.

Comparisons: 42CrMo4 vs Similar Alloy Steels

42CrMo4 vs AISI 4140

| Feature | 42CrMo4 | AISI 4140 |

|---|---|---|

| Standard | EN | ASTM/AISI |

| Carbon Range | 0.38–0.45 | 0.38–0.43 |

| Manganese Range | 0.60–0.90 | 0.75–1.00 |

| Typical Use | Europe & Asia | US & Global |

| Performance | Equivalent | Equivalent |

Conclusion: Chemically and mechanically, 42CrMo4 ≈ 4140; selection is mostly dictated by regional standards and certification requirements.

42CrMo4 vs 42CrMo

| Feature | 42CrMo4 | 42CrMo |

|---|---|---|

| Molybdenum | Present | Sometimes lower |

| Toughness | Higher | Moderate |

42CrMo4 offers better toughness and temper resistance due to controlled molybdenum levels.

42CrMo4 vs 40CrNiMo

40CrNiMo typically has nickel added, increasing low‑temperature toughness, but also increases cost.

42CrMo4 balances cost and performance for most structural applications.

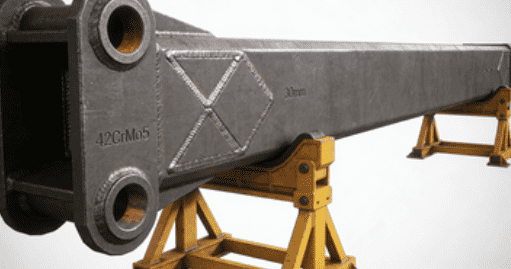

Typical Industrial Applications

Automotive Industry

- Crankshafts & Camshafts: Operate under cyclic loads with fatigue requirements.

- Steering and Suspension Components: Must be tough and resilient.

Heavy Machinery

- Gears & Shafts: High torsional loads demand high toughness and ware resistance.

- Couplings & Pins: Wear and shock load resistance.

Aerospace Sector

- Landing Gear Components: High safety factors with stringent certification.

- Actuator Shafts: Must withstand fatigue under dynamic loads.

Case Example: Automotive Drive Shaft

A global OEM reported that switching from generic medium carbon steel to 42CrMo4 increased service life by 30% under high torque testing.

Machining, Welding & Fabrication

Machinability

- Annealed Condition: Excellent machinability with conventional tooling.

- Hardened Condition: Requires carbide tooling and controlled feeds.

Welding Practices

- Preheat to 150–200 °C to reduce thermal gradients.

- Avoid welding large sections without stress relief to prevent cracking.

Fabrication Tips

- Avoid cold working before heat treatment.

- Post‑weld temper improves consistency of mechanical properties.

Design & Engineering Considerations

When deciding whether 42CrMo4 is right for your part:

Load Type

- Cyclic/Fatigue Loads: High endurance limit.

- Static Compression: Strong yield strength.

Component Geometry

- Thin vs thick sections respond differently to quench rates — plan fixtures accordingly.

Operating Temperature

- Below ~300 °C: Typical

- Above 400 °C: Ratio of strength decreases; consider specialized alloys.

Cost, Availability & Lifecycle Value

Material Cost

- Slightly higher than basic carbon steels due to alloying elements.

- Comparable globally due to widespread production.

Total Cost of Ownership

42CrMo4’s extended service life often results in lower lifecycle costs when compared to unalloyed steels in demanding applications.

Safety, Failure Modes & Prevention

Common Failure Modes

- Fatigue Crack Initiation: Can occur at stress concentrators; use fillets and proper radii.

- Over‑temper Brittleness: Tempered too high loses strength.

Prevention

- Proper heat treatment control.

- Surface treatments (e.g., shot peening) to improve fatigue life.

Expert Insights (Authoritative Views)

Dr. Michael Adams, Metallurgical Engineer

“42CrMo4 steel number denotes a balanced engineering alloy — its versatility across hardening responses and predictable behavior under load make it a first choice for rotating and highly stressed components.

Industry Report (SAE International)

“Steel grades like 42CrMo4 consistently outperform basic carbon steels in fatigue and wear tests, making them indispensable in drivetrain and aerospace structural applications.”

Conclusion

The 42CrMo4 steel number encapsulates a proven engineering alloy with excellent mechanical properties, reliable heat treatment behavior, and broad industrial acceptance. By understanding its composition, heat response, comparison with similar grades, and real‑world performance data, engineers and buyers can confidently select 42CrMo4 for applications demanding strength, toughness, and lifecycle value.

FAQ

What does the 42CrMo4 steel number mean?

It denotes roughly 0.42% carbon and the presence of chromium & molybdenum in an alloy steel standardized under EN 10083‑3.

Is 42CrMo4 the same as 4140?

Yes — they are equivalent grades under different standards (EN vs ASTM/AISI).

Can 42CrMo4 be welded?

Yes, with preheat and proper stress relief; otherwise, cracking can occur.

What hardness can 42CrMo4 steel achieve?

Depending on heat treatment, typically 28–40 HRC for structural applications.

Where is 42CrMo4 most commonly used?

In automotive shafts, gears, heavy machinery parts, and aerospace components requiring high strength and toughness.

Is 42CrMo4 suitable for high temperature?

Below ~300 °C it performs well; above that, consider alloys designed for elevated temperatures.