5 Incredible 1020 Steel Properties Forms Guide

Table of Contents

Introduction

1020 steel is one of the most widely used low carbon steels in manufacturing and construction. For buyers, engineers, and procurement managers in B2B industries, understanding the different forms and supply conditions of 1020 steel is essential to make the right sourcing decisions. This guide explores the incredible versatility of 1020 steel properties, highlights its applications in various forms such as plates, bars, rods, and tubes, and explains how supply conditions impact performance, cost, and usability.

The purpose of this article is to provide a structured, in-depth exploration of the forms and properties of 1020 steel. By the end, readers will have a clear understanding of what factors matter when choosing 1020 steel, how different supply conditions change the mechanical outcomes, and what practical considerations buyers must keep in mind.

Why 1020 Steel Properties Matter for Industrial Buyers

For industrial buyers, making the correct material choice goes beyond cost. Decisions about steel grades affect product strength, machinability, welding ease, and long-term reliability. 1020 steel properties are especially important because the low carbon content provides excellent balance between strength and ductility, making it suitable for machining, forming, and fabrication. Buyers often need steel that can be supplied in multiple forms, such as hot rolled plates for structural parts or cold drawn bars for precision machining. Each form changes how the material performs in practice.

5 Common Forms of 1020 Steel Explained

Different forms of steel offer specific advantages to buyers depending on the application. Below are the most common supply forms:

1020 Steel Plates and Sheets

Plates and sheets are essential in structural applications and fabrication. Plates are thicker, making them suitable for load-bearing applications, while sheets are thinner and used for stamped or formed components.

1020 Steel Bars and Rods

Bars and rods are widely used for machining into shafts, pins, and fasteners. Bars can be round, square, or flat. Cold drawn bars offer superior dimensional accuracy compared to hot rolled bars.

1020 Steel Tubes

Tubes are popular in mechanical systems, automotive components, and fluid transport applications. Seamless tubes are preferred for high-stress applications, while welded tubes are cost-effective for general use.

1020 Steel in Hot Rolled Form

Hot rolled steel is processed at high temperatures, resulting in lower cost but less dimensional accuracy. It is suitable for construction or applications where surface finish is not critical.

1020 Steel in Cold Drawn Form

Cold drawn steel is produced at room temperature, giving it better strength, tighter tolerances, and a smoother surface finish. This form is ideal for precision engineering.

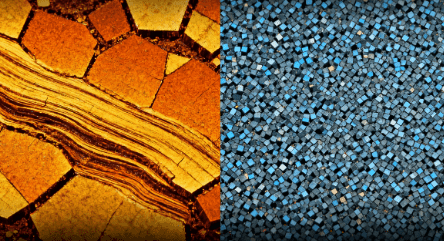

Comparing Hot Rolled vs Cold Rolled 1020 Steel Properties

The rolling process significantly impacts steel performance. Hot rolled steel offers affordability and ease of fabrication, but its looser tolerances may not suit precise components. Cold rolled steel, by contrast, provides higher strength and superior dimensional stability, which is why it is chosen for shafts, gears, and other precision parts. Buyers often compare these two supply conditions based on their production requirements.

Benefits of Annealed 1020 Steel Supply Conditions

Annealing involves heating the steel and then cooling it slowly to improve ductility and machinability. Annealed 1020 steel is easier to form and machine, making it a preferred choice for industries that require extensive shaping or machining. Buyers seeking a balance of cost and performance often choose annealed forms when surface finish and workability are priorities.

Comparison of 1020 Steel Forms and Properties

| Form / Condition | Key Features | Typical Applications | Buyer Considerations |

|---|---|---|---|

| Plate / Sheet | Varying thickness, good weldability | Structural parts, formed components | Plate thickness affects cost and weight |

| Bars / Rods | Round, square, flat; cold drawn or hot rolled | Shafts, pins, fasteners | Dimensional accuracy critical for machining |

| Tubes | Seamless or welded | Automotive, fluid systems, frames | Seamless for high stress; welded for cost savings |

| Hot Rolled | Lower cost, rougher surface, looser tolerances | General construction, fabrication | Suitable where precision is less critical |

| Cold Drawn | Higher strength, tighter tolerances, smoother finish | Precision components | Higher cost but superior quality |

Dimensional Tolerances in 1020 Steel Stock

Buyers often underestimate the importance of dimensional tolerances. Cold drawn bars, for example, can achieve tolerances as tight as ±0.1 mm, while hot rolled bars may have larger deviations. For industries requiring high precision, such as automotive or aerospace, the choice of form directly influences production success.

Why Surface Finish Matters for 1020 Steel Properties

Surface finish affects how steel interacts with coatings, welding, and machining processes. Cold drawn and ground surfaces provide better adhesion for coatings and less wear during machining. Hot rolled surfaces may need additional finishing operations before final use. Buyers should consider whether surface quality impacts downstream processes.

Best Practices for Machining 1020 Steel Bars

Machining performance is one of the most critical factors for buyers. 1020 steel is relatively easy to machine, especially in annealed form. However, work hardening can occur if cutting speeds and feeds are not optimized. Buyers should confirm machinability data with suppliers before committing to large orders.

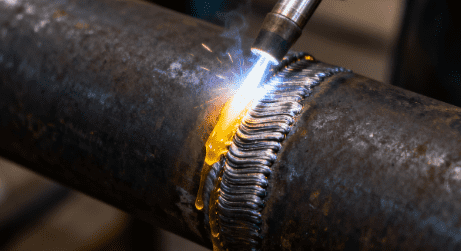

Welding Considerations for 1020 Steel Tubes

Weldability is another area where buyers seek clarity. Thanks to its low carbon content, 1020 steel welds easily with most standard welding processes. However, tubes used in high-pressure environments must be welded with care to prevent stress cracks. Post-weld heat treatment may be advisable in certain applications.

Cost Comparison of 1020 Steel Shapes

Cost varies significantly depending on the form and supply condition. Hot rolled plates are the most economical, while cold drawn precision bars are more expensive due to additional processing. Tubes can also differ greatly depending on whether they are seamless or welded. Buyers must balance budget constraints with performance needs.

Which 1020 Steel Form Is Most Cost-Effective?

The answer depends on the buyer’s application. For heavy structural parts where tolerances are less critical, hot rolled plates offer the best value. For precision-engineered parts, cold drawn bars, though more expensive, provide long-term savings by reducing machining time and improving quality consistency. Buyers should evaluate total lifecycle cost rather than just raw material price.

Mechanical Testing for 1020 Steel Quality Assurance

Buyers are increasingly focused on quality assurance. Mechanical tests such as tensile testing, hardness checks, and impact tests provide data to ensure the steel meets specifications. Verifying these properties before purchase reduces the risk of part failure and production delays.

How Different Forms Affect 1020 Steel Machinability

Bars, rods, and tubes each machine differently due to surface condition, dimensional accuracy, and supply treatment. Cold drawn bars typically offer the best machinability because of their consistent properties. Hot rolled material may require more effort to achieve tight tolerances.

Buyer’s Guide to 1020 Steel Tubing Dimensions

Tubes are supplied in multiple dimensions and wall thicknesses. Buyers must confirm internal diameter, outer diameter, and wall thickness tolerances to ensure compatibility with assembly requirements. For high-stress systems, seamless tubing provides greater reliability, though at a higher cost.

Comparing Fatigue Strength Across 1020 Steel Shapes

Fatigue performance is critical for parts subjected to cyclic loading. Cold drawn bars generally show better fatigue resistance than hot rolled bars due to their refined grain structure. Tubes, depending on whether they are seamless or welded, may also display differences in fatigue strength.

Tips for Reducing Waste When Ordering 1020 Steel

Buyers can minimize waste by ordering material in dimensions close to the finished product size. Working with suppliers to obtain standard stock lengths or custom cut lengths helps reduce scrap. Considering tolerances and finish requirements at the procurement stage also cuts down on unnecessary rework.

Safety Considerations When Handling 1020 Steel

Handling steel safely is an important aspect of procurement. Plates and bars can be heavy and require mechanical lifting equipment. Tubes need careful stacking to prevent rolling hazards. Buyers should ensure suppliers follow safety packaging and transport standards to prevent workplace injuries.

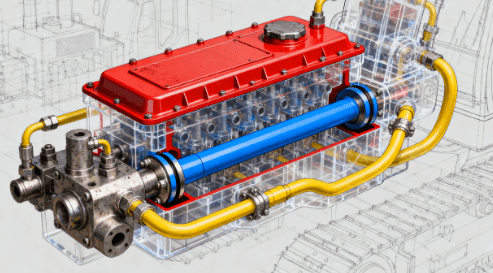

1020 Steel Properties in Heavy Equipment Manufacturing

Heavy equipment relies on materials that can withstand stress, vibration, and wear. 1020 steel is frequently chosen for gears, shafts, and support components. The choice of form—plate, bar, or tube—depends on the part design. Buyers in this sector prioritize both durability and cost efficiency.

Conclusion

1020 steel is a versatile material that provides buyers with flexibility in both form and function. Understanding how 1020 steel properties vary across plates, bars, rods, tubes, hot rolled, cold drawn, and annealed conditions helps buyers make more informed sourcing decisions. By considering tolerances, machining performance, weldability, surface finish, and overall lifecycle cost, industrial buyers can align material selection with production needs.

This guide demonstrated the importance of evaluating different forms, highlighted practical considerations for each, and offered insights into how buyers can avoid common pitfalls. 1020 steel remains a strong choice across industries, provided procurement decisions are based on careful evaluation of its properties and supply forms.

FAQ

What makes 1020 steel properties attractive for industrial buyers?

1020 steel properties are attractive because they offer a balance between strength, machinability, and weldability. The low carbon content ensures the material remains easy to shape and machine, while still providing sufficient durability for components like shafts, gears, and fasteners. This combination makes it versatile and cost-effective for industries that require both structural and precision parts.

How do different forms of 1020 steel impact its performance?

The performance of 1020 steel varies depending on whether it is supplied as plates, bars, rods, or tubes. Plates and sheets are used in structural or fabricated parts, while bars and rods are ideal for machining into precision components. Tubes, either seamless or welded, are critical for automotive and fluid transport systems. Each form offers unique dimensional tolerances and mechanical performance characteristics.

Why is cold drawn 1020 steel often preferred over hot rolled?

Cold drawn 1020 steel is preferred when dimensional accuracy, higher strength, and a smoother surface finish are required. This form undergoes additional processing that improves tolerance and machinability, making it ideal for precision parts such as shafts and gears. While hot rolled steel is more cost-effective, it lacks the refined surface and tight tolerances that certain industries demand.

What role does annealing play in enhancing 1020 steel properties?

Annealing improves 1020 steel properties by reducing hardness and increasing ductility. This process makes the steel easier to machine and form, which is especially useful for complex fabrication tasks. Buyers who prioritize ease of processing and shaping often choose annealed steel forms, as they lower machining costs and extend tool life during production.

Are there cost differences between 1020 steel forms?

Yes, cost differences exist depending on the form and processing of 1020 steel. Hot rolled plates are usually the most economical choice for structural applications, while cold drawn bars cost more due to their tighter tolerances and superior surface finish. Tubes also vary in price, with seamless options being more expensive but stronger, and welded tubes offering a more affordable alternative for general use.

Which industries benefit most from 1020 steel properties?

Industries such as automotive, construction, heavy equipment manufacturing, and general machining benefit most from 1020 steel properties. Its versatility allows it to be used in gears, shafts, fasteners, and structural parts. The availability of multiple forms ensures that buyers from different sectors can find a cost-effective solution tailored to their specific application needs.