Demystify C45 Steel Bars: 2 Essential Heat Treatments

Table of Contents

Introduction

C45 steel is a high-strength, medium carbon quality steel widely used across various industries, from automotive to heavy machinery. Its versatility stems from a balance of mechanical properties, but to truly unlock its full potential, a thorough understanding of its heat treatments is essential. This blog post will delve into the world of C45 steel bars, exploring their fundamental characteristics and, more importantly, shedding light on the two essential heat treatments – normalizing and quenching & tempering – that are crucial for optimizing their performance and ensuring their suitability for demanding applications. By demystifying these processes, we aim to provide valuable insights into how C45 steel bars are engineered to meet specific strength, hardness, and toughness requirements in various industrial settings.

What are C45 Steel Bars?

C45 is a designation for a specific type of medium carbon quality steel, known for its good strength and moderate cold deformation plasticity. Understanding the nature of C45 steel bars is the first step toward appreciating the significance of its processing.

Definition and Material Analysis

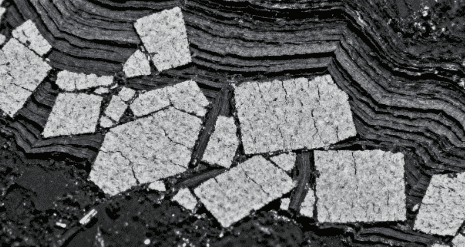

C45 (material number 1.0503) is classified as a medium carbon quality steel with high strength. Due to its relatively low hardenability, C45 steel bars are commonly used in a normalized state. However, when applications demand higher mechanical properties, a quenching and tempering (Q&T) treatment is employed. The cold deformation plasticity of this material is considered medium, and its machinability is better in the annealed or normalized state compared to the quenched and tempered state.

Chemical Composition of C45 Steel Bars

The specific properties of C45 steel bars are primarily defined by its precise chemical composition. The key elements and their ranges are as follows:

- Carbon (C): 0.42-0.50%. Carbon is the primary hardening element in steel.

- Silicon (Si): ≤0.40%. Silicon acts as a deoxidizer and strengthens the ferrite.

- Manganese (Mn): 0.50-0.80%. Manganese improves strength, hardenability, and wear resistance.

- Phosphorus (P): ≤0.045%. Phosphorus is typically an impurity, kept low to prevent brittleness.

- Sulfur (S): ≤0.045%. Sulfur is also an impurity, kept low to avoid hot shortness.

- Chromium (Cr): ≤0.40%. Chromium can improve hardenability and corrosion resistance.

- Molybdenum (Mo): ≤0.10%. Molybdenum can enhance hardenability and high-temperature strength.

- Nickel (Ni): ≤0.40%. Nickel can improve toughness and hardenability.

- Combined Cr+Mo+Ni: ≤0.63%.

These controlled ranges ensure the consistent performance and characteristics of C45 steel bars.

Corresponding Grades and Standards for C45 Steel Bars

C45 steel bars are recognized globally under various equivalent designations and adhere to specific standards. This allows for international trade and material specification.

- European Standard (EN): EN10083-2:2006 or EN 10083/2-1991.

- Chinese Standard (GB): 45#.

- Japanese Standard (JIS): S45C.

- British Standard (BS): 060A47, 080A47, 080M46, IC45.

- French Standard (AFNOR/NF): XC45, CC45.

- German Standard (DIN): C45 (material number 1.0503).

- American Standard (AISI/SAE): 1045.

- Italian Standard (UNI): C45.

- International Standardization Organization (ISO): C45E4.

These equivalences highlight the widespread adoption and standardized nature of C45 steel bars in the manufacturing world.

Delivery Conditions

The initial state in which C45 steel bars are supplied can vary, depending on the agreement between the supplier and the customer. Typically, if no specific agreement is made during ordering, the product is delivered in a non-treated, hot-formed state. However, by agreement, C45 steel bars can also be delivered in annealed, normalized, or quenched and tempered conditions to suit specific manufacturing or application needs.

Essential Heat Treatments for C45 Steel Bars

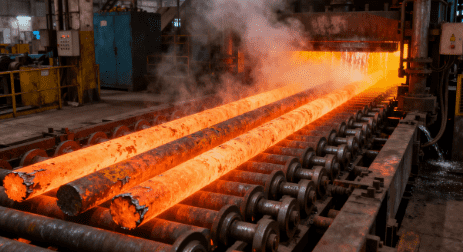

Heat treatment is a critical process that alters the microstructure of C45 steel bars, thereby enhancing or modifying their mechanical properties such as strength, hardness, toughness, and ductility. For C45 steel bars, two essential heat treatments are commonly employed: normalizing and quenching & tempering.

Normalizing of C45 Steel Bars

Normalizing is a heat treatment process primarily used to refine the grain structure, homogenize the microstructure, and reduce internal stresses in C45 steel bars. It involves heating the steel to a specific temperature above its upper critical temperature (Ac3 for hypoeutectoid steels like C45), holding it there for a period, and then cooling it in still air.

- Process Parameters: For C45 steel bars, the normalizing temperature typically ranges from 840 to 880°C. The cooling takes place in air.

- Purpose and Benefits:

- Grain Refinement: Normalizing produces a finer, more uniform grain size, which generally improves both strength and toughness.

- Stress Relief: It effectively reduces internal stresses induced by previous processing like hot working or welding.

- Improved Machinability: For C45 steel bars, normalizing can improve its cutting and machining characteristics, especially compared to the quenched and tempered state.

- Suitable for Large Parts: For larger components, particularly those with section sizes exceeding 80mm, normalizing is often preferred over quenching to avoid issues like cracking and distortion.

- Mechanical Properties (Normalized State): In the normalized condition, C45 steel bars exhibit a good balance of strength and ductility. For example, for thicknesses up to 8mm, the yield strength is ≥340 MPa and tensile strength is ≥620 MPa. As the thickness increases, the values slightly decrease, such as for 20-60mm, yield strength is ≥275 MPa and tensile strength is ≥560 MPa.

Quenching and Tempering of C45 Steel Bars

Quenching and tempering (Q&T), also known as “调质处理” in Chinese, is a more intensive heat treatment aimed at achieving a combination of high strength and good toughness. It involves two main steps: quenching followed by tempering.

- Quenching Process:

- The C45 steel bars are heated to a temperature above the Ac3 point (typically 820-860°C).

- It is then rapidly cooled (quenched) in a medium such as water or oil. This rapid cooling transforms the austenite into martensite, a very hard but brittle microstructure.

- Important Consideration: C45 steel bars have poor hardenability, and water quenching can easily lead to cracks, especially for dangerous sizes like Φ 8-12mm. Therefore, careful control of the quenching process and choice of quenching medium are vital.

- Tempering Process:

- After quenching, the hardened (martensitic) steel bars are reheated to a specific temperature below the Ac1 point (typically 550-660°C).

- This tempering process is then followed by cooling. Tempering reduces the brittleness of martensite, converts some of it into a tougher structure, and alleviates internal stresses, resulting in an optimal balance of strength, ductility, and toughness.

- Purpose and Benefits:

- High Strength and Toughness: Q&T is specifically used when C45 steel bars are required to have higher mechanical properties, providing an excellent combination of high tensile strength, yield strength, and good ductility and impact resistance.

- Suitable for Small to Medium Parts: For small and medium-sized parts, Q&T can yield superior toughness and higher strength compared to normalizing.

- Surface Hardening: After Q&T, C45 steel bars can also undergo surface hardening techniques like high-frequency induction quenching or flame surface quenching, enabling them to replace carburized steel for wear-resistant parts.

Table : Mechanical Properties of C45 Steel Bars in Different Heat Treatment States

| Heat Treatment State | Thickness / Diameter (mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation A% | Reduction of Area Z% | Hardness (HB) | Source |

| Normalized (+N) | ≤8 | ≥340 | ≥620 | ≥14 | – | ≥180 | |

| 8-20 | ≥305 | ≥580 | ≥16 | – | ≥170 | ||

| 20-60 | ≥275 | ≥560 | ≥16 | – | ≥167 | ||

| 250 < d ≤ 500 | ≥305 | 590 – 720 | ≥16 | – | 175 – 209 | ||

| Quenched & Tempered (+QT) | ≤8 | ≥490 | 700-850 | ≥14 | ≥35 | 220 – 270 | |

| 8-20 | ≥430 | 650-800 | ≥16 | ≥40 | 205 – 250 | ||

| 20-60 | ≥370 | 630-780 | ≥17 | ≥45 | 190 – 245 | ||

| 40 < d ≤ 100 | ≥370 | 630 – 780 | ≥17 | ≥45 | 190 – 245 |

Note: Data may vary slightly between different sources and specific production conditions. Hardness for normalized state in is based on diameter (d) and refers to the minimum value for ≤100mm, whereas does not explicitly list hardness for normalized state but gives other mechanical properties by thickness.

Why Heat Treatment Matters for C45 Steel Bars

Heat treatment is not just an optional step; it is fundamental to dictating the final mechanical properties and suitability of C45 steel bars for specific engineering applications. Without appropriate heat treatment, C45 steel bars might not possess the required strength, hardness, toughness, or fatigue resistance for their intended use. For instance, parts requiring high wear resistance or subjected to significant dynamic loads will benefit immensely from quenching and tempering, while larger, less critically stressed components might find normalized steel bars perfectly adequate. The choice between normalizing and quenching & tempering hinges on the desired balance of properties for the final product, demonstrating the critical role these processes play in engineering design and material selection.

Applications of C45 Steel Bars

The specific mechanical properties achieved through appropriate heat treatment allow C45 steel bars to be utilized in a broad spectrum of applications across numerous industries. Its balance of strength, machinability, and cost-effectiveness makes it a popular choice for various components.

- Mechanical Manufacturing: C45 steel bars are widely used for manufacturing parts that require relatively high strength. These include gears, shafts, piston pins, connecting rods, worms, racks, and various mechanical machined parts. It is also suitable for forgings, stampings, bolts, nuts, and pipe joints.

- Automotive Industry: Components such as crankshafts, machine tool spindles, and other transmission shafts can be made from C45 steel bars, often after surface hardening treatments like high-frequency induction quenching.

- Heavy and General Machinery: This material is applied in rolling shafts and impellers for steam turbines.

- Agricultural Machinery: C45 steel bars are suitable for moderately loaded shafts, threshing rollers, concave teeth, sprockets, and gears in agricultural machinery.

- Other Industries: The versatility of C45 steel bars extends to aerospace, power generation, petrochemicals, marine engineering, electronics, and environmental protection sectors. They are also found in construction machinery, wind power generation, railway, and rail transportation applications. Its use in these demanding fields underscores its reliability and performance when properly processed.

Conclusion

C45 steel bars stand as a testament to the power of material science and engineering, offering a robust solution for a myriad of industrial challenges. As a medium carbon quality steel, it provides a strong foundation, but it is through the precise application of heat treatments—specifically normalizing and quenching & tempering—that its full potential is realized.

Normalizing refines the grain structure and reduces internal stresses, while quenching and tempering dramatically enhance the strength and toughness, tailoring the steel bars to the exact demands of their application. Understanding these essential processes is not merely academic; it is crucial for engineers, manufacturers, and designers in selecting and utilizing C45 steel bars effectively to ensure optimal performance, durability, and safety in critical components across diverse sectors.

FAQ

What are the key characteristics of C45 steel bars?

C45 steel bars are primarily characterized by their relatively high strength for a medium carbon steel. They exhibit moderate cold deformation plasticity and good machinability when in the annealed or normalized state. A notable characteristic is their poor hardenability, which means they typically require more severe quenching mediums like water, but this also increases the risk of cracking, especially for certain dimensions. They possess moderate weldability and are often used in normalized or quenched and tempered conditions to achieve desired mechanical properties.

What is the primary difference between normalizing and quenching & tempering for C45 steel bars?

The primary difference lies in their purpose and the resulting mechanical properties. Normalizing is a heat treatment aimed at refining the grain structure, homogenizing the microstructure, and relieving internal stresses, leading to a good balance of strength and ductility. It’s often used for larger parts or when extreme hardness isn’t required. Quenching & tempering, on the other hand, is a two-step process designed to achieve significantly higher strength and hardness coupled with good toughness. It involves rapid cooling (quenching) to form martensite, followed by reheating (tempering) to reduce brittleness and improve toughness. This treatment is typically applied to smaller to medium-sized parts requiring superior mechanical performance.

Can C45 steel bars be welded?

C45 steel bars generally have lower weldability compared to low-carbon steels. Due to its medium carbon content, C45 steel bars are susceptible to cold cracking in the heat-affected zone if proper welding procedures are not followed. Preheating, controlled interpass temperatures, and post-weld heat treatment (such as stress relieving) are often necessary to achieve a sound weld and mitigate the risk of cracking.

What are common equivalent grades for C45 steel bars internationally?

C45 steel bars have several internationally recognized equivalent grades. In China, it’s known as 45# steel. In Japan, it corresponds to S45C. The American AISI/SAE standard equivalent is 1045. Other equivalents include German DIN C45 (1.0503), British 080A47/080M46, and French XC45, among others. These equivalences facilitate global material sourcing and specification.