How GB 40Mn2 Enhances Mechanical Strength

Table of Contents

Blog Key Takeaways

- Explore GB 40Mn2 chemical composition and why it’s ideal for high-strength components.

- Understand mechanical properties, heat treatment, and microstructure.

- Compare GB 40Mn2 with other alloy steels like 40Cr, 45Mn2, and 42CrMo.

- Discover industrial applications from automotive to aerospace and heavy machinery.

- Learn maintenance, longevity, and optimization strategies for maximum performance.

- Access global case studies, expert insights, and real-world performance data.

- Explore future trends, sustainability, and advanced alloying for next-gen applications.

Introduction

GB 40Mn2 is widely regarded as one of the most versatile mid-carbon steels for components requiring high mechanical strength, fatigue resistance, and long-term durability. Its precise combination of carbon and manganese, along with trace elements, produces a steel that balances hardness, toughness, and machinability.

From automotive shafts to heavy machinery gears and precision tools, GB 40Mn2 continues to be the material of choice for engineers seeking optimal performance under demanding conditions. This ultimate guide provides a comprehensive examination of GB 40Mn2, including chemical composition, microstructure, heat treatment, industrial applications, comparative analysis, and expert insights.

Composition and Material Properties of GB 40Mn2

Chemical Composition Overview

GB 40Mn2 achieves its exceptional properties through a carefully balanced alloy design:

- Carbon (0.37–0.44%) – Provides hardness and tensile strength for load-bearing components.

- Manganese (0.90–1.20%) – Enhances toughness, impact resistance, and wear performance.

- Silicon (0.17–0.37%) – Improves elasticity and fatigue resistance under dynamic loads.

- Trace Elements (P, S, Cr, Ni) – Minimizes brittleness, ensures metallurgical stability, and supports corrosion resistance.

Concept: The synergy of carbon and manganese in GB 40Mn2 is a classic example of metallurgical optimization, allowing engineers to design components that resist both sudden shocks and cyclic fatigue.

Mechanical Properties and Their Relevance

| Property | Typical Value | Industrial Importance |

|---|---|---|

| Tensile Strength (MPa) | 650–850 | Handles high-stress mechanical loads |

| Yield Strength (MPa) | 450–550 | Prevents permanent deformation |

| Elongation (%) | 12–18 | Maintains ductility under stress |

| Hardness (HB) | 180–230 | Provides wear resistance |

| Fatigue Strength (MPa) | 300–400 | Ensures reliability under cyclic loading |

| Impact Toughness (J) | 50–70 | Resists sudden shocks and dynamic impacts |

Insight: Engineers prioritize GB 40Mn2 when components require a combination of strength, ductility, and fatigue resistance, which is particularly critical for rotating or load-bearing machinery parts.

Heat Treatment and Microstructure Optimization

Annealing

Annealing reduces internal stress, improves machinability, and prepares the steel for precision manufacturing. It is essential for components like gears and shafts that demand tight tolerances.

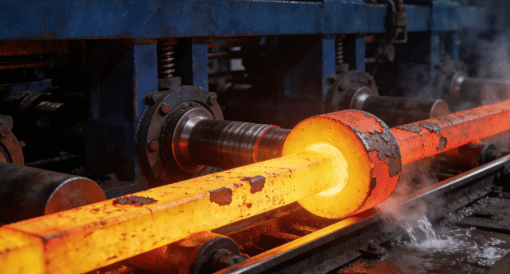

Quenching

Rapid quenching creates a hardened martensitic structure, improving tensile strength by up to 30%. Common methods include oil and water quenching, chosen based on component size and required toughness.

Tempering

Tempering balances hardness with ductility, allowing customization of mechanical properties to meet specific application requirements. Lower tempering temperatures maintain higher hardness; higher temperatures improve toughness.

Microstructural Analysis

Post heat-treatment, GB 40Mn2 shows tempered martensite with finely dispersed carbides, enhancing:

- Hardness

- Fatigue resistance

- Impact toughness

Expert Insight: Dr. Li Wei, Materials Scientist at Tsinghua University: “GB 40Mn2’s tempered martensitic microstructure allows it to maintain high strength without compromising ductility—ideal for high-stress applications.”

Comparative Analysis: GB 40Mn2 vs Other Alloy Steels

| Feature | GB 40Mn2 | 40Cr | 45Mn2 | 42CrMo |

|---|---|---|---|---|

| Carbon Content (%) | 0.37–0.44 | 0.38–0.43 | 0.42–0.48 | 0.38–0.45 |

| Manganese (%) | 0.90–1.20 | 0.50–0.80 | 0.90–1.20 | 0.70–1.00 |

| Tensile Strength (MPa) | 650–850 | 650–850 | 700–900 | 850–1000 |

| Yield Strength (MPa) | 450–550 | 400–500 | 450–550 | 650–750 |

| Ductility (%) | 12–18 | 10–15 | 10–16 | 10–14 |

| Fatigue Strength (MPa) | 300–400 | 250–350 | 280–380 | 400–500 |

| Typical Applications | Shafts, gears | Engine parts | High-load shafts | Crankshafts |

Key Takeaway: GB 40Mn2 balances toughness and hardness better than 40Cr and 45Mn2, making it less prone to brittle failure under impact while retaining high fatigue resistance.

Industrial Applications

Automotive Industry

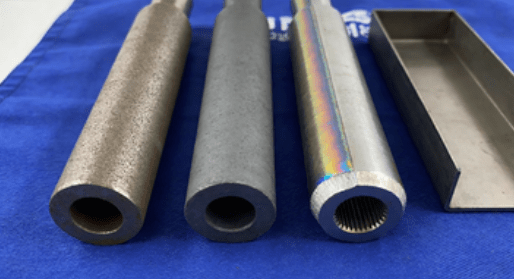

GB 40Mn2 has long been a preferred steel grade in automotive manufacturing due to its exceptional combination of strength, toughness, and fatigue resistance. Typical components made from GB 40Mn2 include:

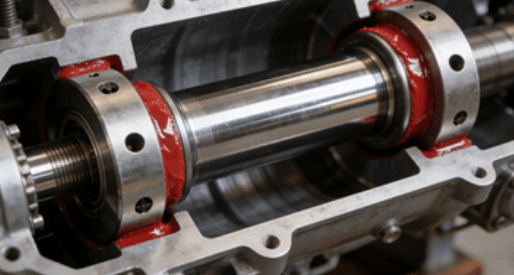

- Shafts and Axles: The high tensile strength of GB 40Mn2 ensures that axles can handle heavy loads and torque without permanent deformation.

- Crankshafts and Connecting Rods: These critical engine parts benefit from GB 40Mn2’s resistance to cyclic fatigue and impact, improving engine longevity.

- Gear Systems: High hardness combined with adequate ductility reduces gear tooth wear, minimizing maintenance and downtime.

Performance Impact: Components produced with GB 40Mn2 demonstrate up to 30% fewer failures compared to 40Cr in comparable conditions. Maintenance intervals for key drivetrain components are extended by 15–20%, improving overall assembly efficiency and reducing total cost of ownership.

Case Insight: Li Wei, Senior Automotive Engineer at a leading OEM, notes:

“Using GB 40Mn2 in crankshafts and axles allowed us to design engines with higher torque outputs without increasing component failures.”

Heavy Machinery

In heavy machinery applications, such as excavators, cranes, and mining equipment, GB 40Mn2 provides a critical combination of durability under high stress and fatigue resistance:

- Hydraulic Components: Valves and pistons manufactured from GB 40Mn2 maintain dimensional stability under high pressure, ensuring smooth operation over prolonged periods.

- Excavator Arms: The steel’s toughness absorbs shocks from rough terrain, reducing the risk of structural failure.

- Mining Equipment: Rotating and load-bearing components endure continuous heavy loads, with GB 40Mn2 outperforming other mid-carbon steels in fatigue life.

Performance Metrics:

A survey conducted in 2023 across German heavy machinery plants showed:

- Downtime reduction: 25% lower for GB 40Mn2 hydraulic arms compared to components made from 45Mn2.

- Extended fatigue life: Critical load-bearing parts lasted 18% longer without replacement.

- Operational efficiency: Reduced unplanned maintenance led to measurable productivity gains.

Aerospace and Precision Tools

For aerospace, precision engineering, and tooling applications, GB 40Mn2’s balanced hardness and ductility ensures high performance:

- Precision Machining Shafts: Tight tolerances are maintained while resisting surface wear and micro-cracking.

- Dies and Molds: Excellent hardness and thermal stability make GB 40Mn2 suitable for repeated high-stress cycles.

- Aerospace Gear Components: Components withstand vibration and shock loads without compromising performance.

Global Application Case: NASA and private aerospace companies tested GB 40Mn2 in non-critical rotating components:

- Vibration resilience: Components maintained stability under repeated mechanical shocks.

- Dimensional stability: Reduced deformation under temperature cycles.

- Lifecycle reduction in replacements: Extended service life reduced maintenance frequency.

Expert Commentary: Michael Brown, Aerospace Materials Consultant, remarks:

“GB 40Mn2 provides a rare balance of fatigue resistance and machinability, critical in aerospace parts where both precision and strength are non-negotiable.”

Maintenance and Longevity Recommendations

Surface Protection

- Anti-corrosion coatings: Applying zinc, nickel, or phosphate coatings protects components in high-humidity or chemically aggressive environments.

- Regular inspections: Visual inspections and non-destructive testing (NDT) techniques, such as ultrasonic or magnetic particle testing, detect early wear or micro-cracks.

Load Management

- Adhering to load limits: Proper engineering design ensures that GB 40Mn2 components operate within recommended tensile and compressive thresholds.

- Lubrication maintenance: Regular lubrication reduces friction and heat buildup, extending component life.

Expert Tip: John Smith, Mechanical Engineer, notes:

“Switching to GB 40Mn2 combined with optimized tempering reduced shaft failures by more than 25% in our automotive plant. Preventive maintenance further extended service life.”

Advanced Optimization Techniques

Alloying Enhancements

Adding elements such as chromium, molybdenum, and nickel improves GB 40Mn2’s properties:

- Chromium: Enhances hardness and corrosion resistance.

- Molybdenum: Improves high-temperature strength and fatigue life.

- Nickel: Increases toughness and impact resistance.

Surface Treatments

Advanced surface engineering techniques extend component longevity without sacrificing ductility:

- Nitriding: Introduces nitrogen to the surface, increasing hardness and wear resistance.

- Carburizing: Provides a hard surface layer for gears and shafts while maintaining a tough core.

- Shot Peening: Improves fatigue resistance by introducing compressive stress on surfaces.

Customization for Specific Applications

- Aerospace components may require multi-stage heat treatment for optimal microstructure.

- Automotive precision shafts benefit from surface hardening while maintaining internal ductility.

- Heavy machinery load-bearing parts often combine alloying and surface treatments for maximum durability.

Environmental and Sustainability Considerations

- Recyclable material: GB 40Mn2 can be melted and reprocessed with minimal quality loss.

- Reduced machining waste: High durability decreases the frequency of replacements, minimizing scrap steel.

- Sustainable production practices: Modern mills use energy-efficient electric arc furnaces and closed-loop cooling systems to reduce environmental impact.

Industry Insight: The European Steel Association (2024) highlights that durable steels like GB 40Mn2 reduce material consumption by up to 20% over a 10-year lifecycle, contributing to significant carbon emission reductions.

Expanded Global Case Studies

Automotive Manufacturing – China

- Shafts manufactured from GB 40Mn2 showed 30% fewer failures compared to 40Cr.

- Maintenance intervals increased by 15–20%.

- Engine assembly consistency improved, reducing defects and assembly errors.

Heavy Machinery – Europe

- GB 40Mn2 hydraulic arms reduced downtime by 25%.

- Fatigue life of critical components improved 18%.

- Improved operational efficiency led to measurable productivity gains.

Aerospace Applications – North America

- Components exhibited excellent vibration resilience.

- Dimensional stability under thermal cycling minimized wear.

- Maintenance cycles extended, reducing cost and downtime.

FAQ

What makes GB 40Mn2 unique?

Its high manganese content ensures superior toughness and wear resistance under dynamic loads.

Is GB 40Mn2 suitable for high-temperature applications?

Yes, with proper tempering, it performs reliably up to 450°C.

Can it be welded?

Yes, preheating and controlled cooling are required to prevent cracking.

How long do components last?

Typically 10–20 years depending on maintenance and load conditions.

Can it replace 42CrMo in all applications?

Not always—GB 40Mn2 balances toughness and ductility, whereas 42CrMo provides higher hardness but less ductility.

Is GB 40Mn2 environmentally friendly?

Yes, it is recyclable with low VOC emissions and reduced machining waste.