Unlocking the Potential of Stainless Steel Billet in Modern Industries

When we think about stainless steel, we often envision finished products like kitchen utensils, car parts, or construction materials. But before any of these items are made, they all begin with a fundamental component: the stainless steel billet. This raw material serves as the starting point for a vast array of industrial applications, yet it often goes unnoticed in the final product.

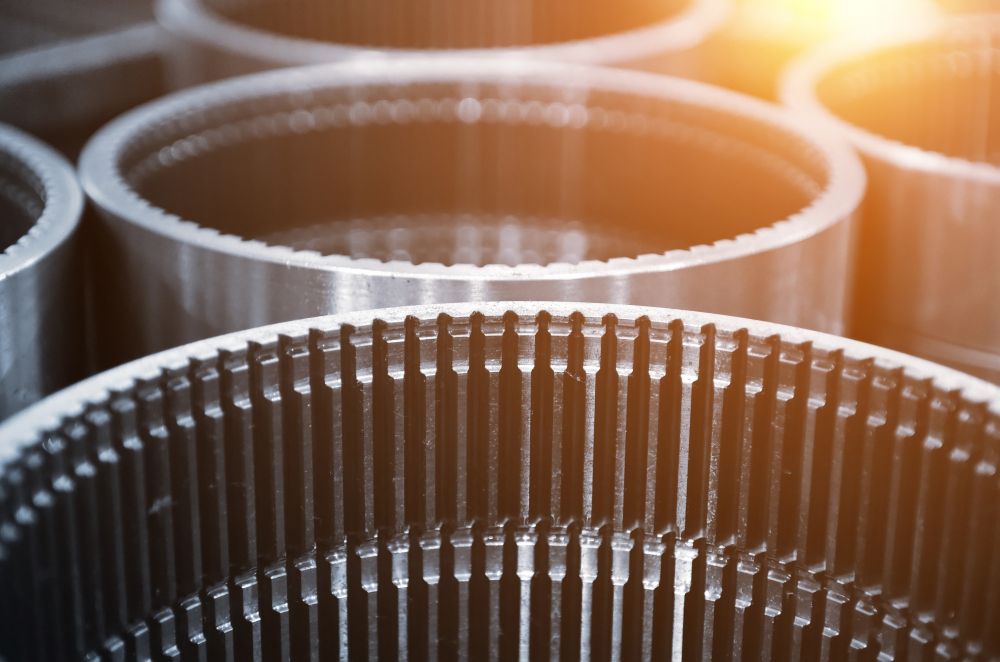

A stainless steel billet is a solid, cylindrical block of steel, carefully crafted through a complex process of alloying and casting. Its versatility lies in the fact that it can be shaped, formed, and refined to meet the specific needs of various industries, from aerospace to construction. But how exactly does this seemingly simple product play a vital role in modern manufacturing?

Table of Contents

The Journey from Billet to Finished Product: A Snapshot of the Process

While stainless steel billet starts as a solid chunk of metal, its journey is far from simple. After casting, the billet undergoes various processes such as hot rolling, forging, and machining to transform into usable products. Here’s a brief look at the journey:

- Casting: The raw steel is first melted and poured into molds to create the billets. This process ensures uniformity in size and shape.

- Hot Rolling: The billets are heated to high temperatures and passed through rollers, making them thinner and longer. This process is essential for shaping the material into usable forms like rods, bars, or sheets.

- Forging and Machining: Depending on the final product, the billet can undergo forging or machining to achieve the required dimensions and surface finish.

This transformation is what makes the stainless steel billet so versatile and valuable to manufacturers across multiple sectors.

Beyond the Basics: Where Stainless Steel Billet Makes a Difference

You might wonder where this fundamental material plays a critical role in various industries. Although stainless steel billets often stay out of the spotlight, they are indispensable in sectors where strength, durability, and corrosion resistance are absolutely essential. Here are several industries that heavily rely on this raw material.

- Aerospace: The aerospace industry demands high-performance materials capable of withstanding extreme temperatures and pressures. Stainless steel billets are used to create various engine components and structural parts, ensuring safety and reliability in flight.

- Automotive Manufacturing: For car parts like exhaust systems and engine components, stainless steel billets provide the perfect balance of strength and resistance to corrosion, making them an ideal choice for vehicles that must endure harsh environments.

- Medical Devices: In the medical field, where hygiene and strength are paramount, stainless steel billets are transformed into surgical instruments, implants, and equipment that require precise manufacturing and long-term durability.

- Construction and Infrastructure: Stainless steel is known for its resistance to rust and corrosion, making it a popular material for constructing buildings, bridges, and even in infrastructure like pipelines. The stainless steel billet is essential in providing the necessary material strength to withstand the test of time.

These industries all rely on stainless steel billets for creating durable, reliable, and efficient products. What they all have in common is the need for a raw material that can be molded, shaped, and adapted for specific needs.

Advantages of Stainless Steel Billet: More Than Just Strength

When most people think of stainless steel billet, they focus on its raw strength and resistance to corrosion. But its true value lies in the combination of properties that make it suitable for a wide range of applications. Here’s a breakdown of its key advantages:

- Corrosion Resistance: Stainless steel is resistant to rust, oxidation, and corrosion, even in extreme conditions, making it ideal for use in marine environments or chemical processing plants.

- High Strength-to-Weight Ratio: It offers excellent strength without being overly heavy, which is crucial in industries like aerospace and automotive manufacturing where weight is a critical factor.

- Versatility in Fabrication: A stainless steel billet can be easily shaped into various forms without compromising its integrity, allowing it to be used in a wide variety of finished products.

- Longevity and Durability: Stainless steel’s durability ensures that products made from stainless steel billets will have a long service life, reducing the need for frequent replacements and maintenance.

These characteristics not only enhance the performance of the final products but also improve overall cost efficiency by reducing maintenance and improving service life.

The Future of Stainless Steel Billet: Trends and Innovations

As industries continue to evolve, so too does the demand for stainless steel billets. One of the key drivers of future developments will be advancements in steel billet production technologies. With new manufacturing techniques on the horizon, the production of billets is expected to become more cost-effective, energy-efficient, and environmentally friendly.

- Smarter Manufacturing Processes: With the rise of automation and smart manufacturing, the precision of creating stainless steel billets will improve. This means higher quality control, reduced waste, and more consistent final products.

- Sustainability in Steel Production: As industries push toward sustainability, recycling and reusing steel billets will become more prominent. The focus will shift to reducing the environmental impact of steel production while maintaining the same high-quality output.

- Alloy Innovations: Researchers are working on creating new stainless steel alloys that are even stronger, lighter, and more resistant to extreme conditions. These innovations will further expand the use of stainless steel billets in industries where high performance is non-negotiable.

The future of stainless steel billets is promising, with the potential for even more versatile applications and efficient production methods that will benefit industries worldwide.

Conclusion

automotive to construction, it serves as the backbone of many industries. Its inherent properties make it an indispensable material, capable of adapting to the needs of any manufacturing process. As technology continues to evolve, so too will the capabilities of stainless steel billets, shaping the future of production and innovation.

Manufacturers who rely on stainless steel billets are not just choosing a material—they are investing in a product that will withstand the test of time, ensuring that the finished products are reliable, durable, and effective. Looking ahead, the demand for high-quality stainless steel billets will only grow, solidifying its position as a key player in the future of manufacturing.