From Steel Billet to Damascus Steel Billet: The Craft of Transforming Raw Material into Masterpieces

In the world of steel production, Steel Billet serves as the raw material that forms the foundation for a wide range of applications. However, there is a particular type of billet that stands out due to its historical significance and modern-day appeal: the Damascus Steel Billet. Known for its unique layered pattern and exceptional performance, the transition from a regular steel billet to a Damascus steel billet involves intricate craftsmanship and advanced techniques. This article will explore how Steel Billet is transformed into Damascus Steel Billet and why it is considered a symbol of strength, beauty, and durability in the steel industry.

Table of Contents

What is Steel Billet and How is it Made?

Before we dive into the transformation process, it’s important to understand the fundamentals of Steel Billet. Steel billets are semi-finished products that are produced from steel ingots. They are typically rectangular or square in shape and serve as the primary form used to produce a wide range of products in industries such as construction, automotive, and machinery.

The production of Steel Billet involves heating steel to a molten state and then casting it into molds to form billets. This basic process gives the billets their strength, flexibility, and resistance to high stress. These properties make billets suitable for many structural and industrial applications.

However, the Steel Billet used in the creation of Damascus steel billets undergoes additional refinement. The billets are carefully selected for their quality, ensuring they are the ideal candidates for the next stage of crafting.

The Art of Crafting Damascus Steel Billet

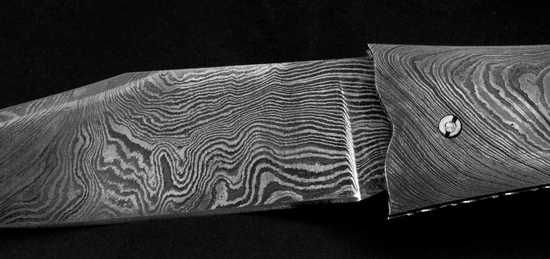

The transformation from Steel Billet to Damascus Steel Billet is nothing short of an art form. Damascus steel is known for its striking appearance—characterized by flowing, intricate patterns that are formed by the fusion of different steel layers. This transformation begins with the heating of Steel Billet to a molten state, followed by the addition of various types of steel, including carbon and stainless steel, to create a multi-layered effect.

Once the materials are stacked and forged, they are folded repeatedly to create multiple layers of steel. This process, known as folding, is crucial in developing the beautiful, flowing patterns in Damascus steel. Each time the billet is folded, it increases the number of layers, resulting in the stunning, patterned surface that Damascus steel is famous for.

The advantage of using Steel Billet as the base material for Damascus steel lies in its strength and versatility. By combining different billets, artisans can control the thickness and composition of the layers, ultimately determining the performance and appearance of the finished Damascus steel.

Why Steel Billet is Ideal for Damascus Steel Production

So why is Steel Billet the perfect starting point for crafting Damascus Steel Billet? The answer lies in the inherent qualities of Steel Billet. Steel billets are known for their high tensile strength and malleability, making them ideal for repeated folding and forging without losing structural integrity.

The process of creating Damascus steel requires the material to withstand intense heat and stress. As the Steel Billet is heated and folded multiple times, it retains its strength and flexibility, making it possible to create the layered structure that is key to the Damascus steel’s signature patterns.

Furthermore, Steel Billet provides a reliable foundation for artisans to manipulate the steel’s characteristics, adjusting the amount of carbon or alloying elements to achieve the desired properties. The result is a material that combines the best qualities of both strength and beauty.

The Manufacturing Process: From Steel Billet to Damascus Steel Billet

The journey from Steel Billet to Damascus Steel Billet begins with selecting high-quality billets. These billets are heated to extremely high temperatures to make them malleable. At this point, a combination of different types of steel—such as high-carbon steel and low-carbon steel—is layered together.

Once the billets are stacked, the real transformation begins. The stack of layered steel is repeatedly heated, folded, and hammered to meld the layers together. Each time the stack is folded, it is heated again to allow the layers to bond seamlessly, resulting in a steel billet that has a unique layered structure.

This process is repeated several times until the desired number of layers is achieved. The final result is a Damascus Steel Billet that is ready to be shaped into tools, knives, or any other desired product. The combination of heat, pressure, and time creates a billet that is both visually stunning and incredibly strong.

Advantages of Damascus Steel Billet Over Regular Steel Billet

While Steel Billet is a versatile and durable material, Damascus Steel Billet offers several distinct advantages. The multi-layered structure of Damascus Steel Billet not only enhances its visual appeal but also improves its performance in terms of strength, flexibility, and durability.

The folding process creates a surface that is both harder and more resilient, making it ideal for tools that require high endurance, such as knives and swords. The unique patterns on the surface also help to distribute stress more evenly across the material, preventing weak points and ensuring that the final product remains functional and long-lasting.

Moreover, Damascus Steel Billet can be tailored to meet specific requirements, such as increasing hardness for cutting tools or enhancing flexibility for decorative items. This customization makes it a versatile material in both the functional and artistic domains.

Applications of Damascus Steel Billet

The remarkable properties of Damascus Steel Billet make it the preferred material for high-end applications. Traditionally, Damascus Steel was used to create blades for swords and knives, prized for their sharpness and durability. Today, Damascus Steel Billet is still highly sought after in the production of high-quality cutlery, decorative items, and even jewelry.

In modern industries, the unique performance and aesthetic properties of Damascus steel make it a popular choice for manufacturers looking to create premium products. Whether used for crafting precision tools or luxury items, Damascus Steel Billet continues to be a symbol of craftsmanship and durability.

Challenges in Damascus Steel Billet Production

While the process of creating Damascus Steel Billet is fascinating, it comes with its challenges. The forging process is time-consuming and requires high levels of skill and experience. The cost of producing Damascus steel billets is also higher than regular billets due to the labor-intensive process and the need for specialized equipment.

Additionally, the unpredictable nature of the folding process means that each Damascus Steel Billet is unique. This can make it difficult to maintain consistency across large production runs, adding another layer of complexity to the process.

Conclusion

The transition from Steel Billet to Damascus Steel Billet is a journey that combines tradition, craftsmanship, and innovation. The high tensile strength and flexibility of Steel Billet make it an ideal starting point for creating Damascus Steel Billet, allowing artisans to create a material that is as functional as it is beautiful.

Whether used in luxury knives, artistic creations, or functional tools, Damascus Steel Billet continues to captivate enthusiasts and professionals alike. Its enduring appeal lies not only in its historical legacy but also in its modern applications, making it a valuable material in today’s steel industry.