Steel Manufacturing Processes for Automotive Engine Parts

Table of Contents

Introduction

In the world of automotive manufacturing, the selection of materials for engine components is a critical factor that can determine the overall performance, durability, and efficiency of a vehicle. Automotive engine parts, such as engine blocks, pistons, and crankshafts, are subjected to extreme stresses, high temperatures, and constant mechanical wear. To withstand these conditions, steel used in these components must possess a unique combination of strength, toughness, and resistance to fatigue.

This is where steel manufacturing processes come into play. In this blog, we will delve into the role of steel manufacturing processes for automotive engine parts, focusing on how different steel grades and processing techniques contribute to engine efficiency and longevity. As a key player in steel manufacturing, Henan Jiyuan Iron & Steel (Group) Co., Ltd., a renowned Chinese steel manufacturer, plays a pivotal role in providing high-quality steel solutions for the automotive industry. We will explore how Jiyuan’s advanced steel production methods meet the demanding requirements of the automotive sector.

The Role of Steel in Automotive Engine Parts

Steel is a fundamental material in the production of automotive engine components. It is prized for its high strength-to-weight ratio, versatility, and resistance to high temperatures, making it the ideal choice for manufacturing critical engine components. From pistons and crankshafts to engine blocks and valve lifters, steel’s unique properties enable it to withstand the harsh conditions found in automotive engines.

For engine parts, steel must possess the right combination of mechanical properties, including:

- Tensile Strength – Ability to resist pulling forces.

- Hardness – Resistance to indentation or scratching.

- Toughness – Ability to absorb energy before fracturing.

- Fatigue Resistance – Ability to resist repeated loading and unloading without failure.

- Thermal Resistance – Ability to withstand high temperatures without degrading.

Each steel grade used for engine components has specific properties designed for particular uses. The role of steel in automotive engine parts is determined by the manufacturing process and the alloying elements included in the steel to meet the specific demands of automotive engines.

Steel Manufacturing for Automotive Engine Parts

Steel used in automotive engine parts is processed in a way that maximizes performance, durability, and efficiency. There are key processes in steel manufacturing that help tailor the material for use in automotive engines.

Steel Forging vs. Casting: Which is Better for Engine Parts?

One of the first decisions in steel manufacturing for automotive engine parts is the choice between forging and casting. Two primary methods are used to shape steel for engine parts: forging and casting. Both methods have distinct advantages depending on the component being produced.

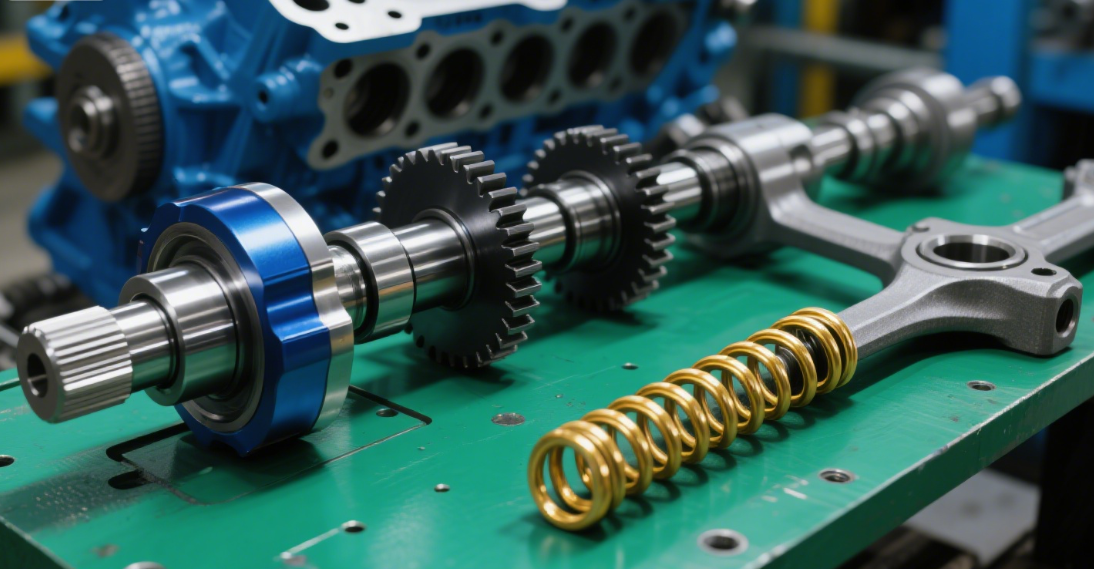

Forging

- Process: Steel is shaped using compressive forces at high temperatures.

- Advantages:

- Grain structure is aligned, improving strength and resistance to fatigue.

- Typically more durable and stronger than cast parts.

- Commonly used for high-stress components like crankshafts, connecting rods, and gears.

- Applications: Crankshafts, connecting rods, camshafts.

Casting

- Process: Molten steel is poured into molds to form the desired shape.

- Advantages:

- More cost-effective, especially for producing complex parts.

- Allows for intricate designs and larger parts.

- Disadvantages:

- Steel may have lower mechanical properties compared to forged parts.

- Potential for defects and reduced structural integrity.

- Applications: Engine blocks, transmission cases, cylinder heads.

Jiyuan Steel’s high-quality forged steel, such as 42CrMo4/4140, provides excellent toughness and fatigue resistance, ideal for high-performance engine parts.

Alloying Elements in Steel for Engine Parts: What You Need to Know

Steel’s mechanical properties can be enhanced by adding alloying elements. The most common elements used in automotive engine steel are:

Chromium

- Benefit: Increases hardness and wear resistance.

- Applications: Camshafts, crankshafts, and gears.

Molybdenum

- Benefit: Improves strength at high temperatures and enhances resistance to thermal degradation.

- Applications: Engine blocks, turbochargers, and exhaust systems.

Nickel

- Benefit: Increases toughness and resistance to impact, crucial for parts exposed to high stress.

- Applications: Engine blocks, connecting rods, and transmission gears.

Vanadium

- Benefit: Enhances fatigue resistance and toughness, especially in high-stress areas.

- Applications: Crankshafts, connecting rods, and axles.

Jiyuan’s high-strength wear-resistant steels provide superior durability for critical automotive engine components exposed to high stresses and extreme environments.

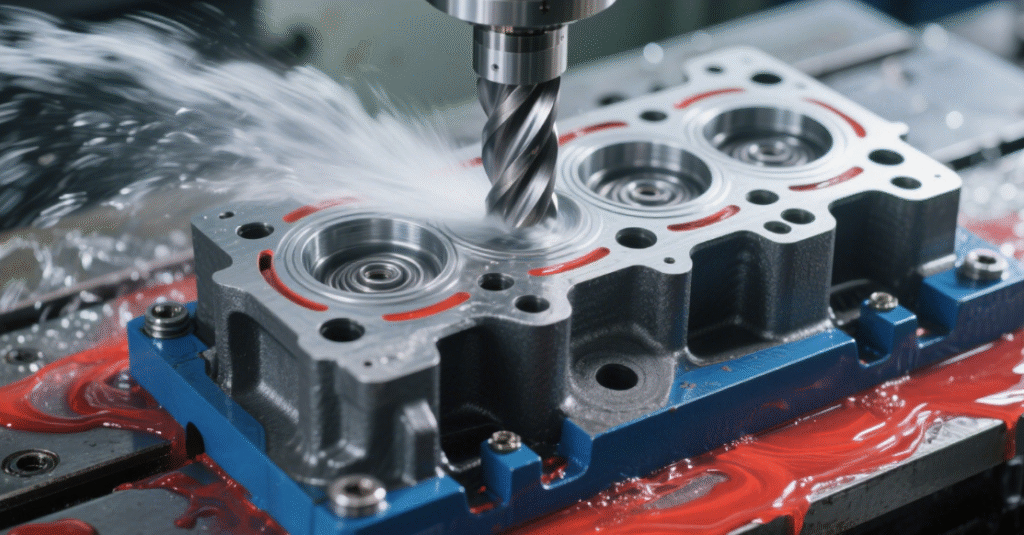

Automotive Steel for Precision Engine Machining

Precision machining is essential for creating engine parts with exact specifications. Steel used for precision components must allow for smooth cutting and detailed shaping.

Key Considerations for Precision Engine Steel:

- Machinability: Steel must be easy to machine without excessive tool wear.

- Surface Finish: Precision parts require a smooth surface for proper functioning.

- Tight Tolerances: The material must meet strict dimensional requirements for optimal engine performance.

Steel grades like SAE 52100 and SCM420H are often chosen for precision engine machining, as they provide an excellent balance of hardness and machinability.

Steel Heat Treatment Methods for Enhancing Engine Part Strength

Heat treatment is a critical step in steel manufacturing that alters the microstructure of the steel to enhance its mechanical Heat treatment significantly influences the strength and toughness of steel. Various methods are employed to tailor steel for automotive applications.

Common Heat Treatment Methods:

- Quenching:

- Process: Rapid cooling of steel from high temperatures.

- Result: Increased hardness but can lead to brittleness.

- Tempering:

- Process: Reheating quenched steel to a lower temperature and then slowly cooling it.

- Result: Reduced brittleness and improved toughness.

- Annealing:

- Process: Heating steel to a specific temperature and then slowly cooling it.

- Result: Increased softness and improved machinability, while reducing internal stresses.

These processes ensure that steel has the right combination of strength, toughness, and machinability for high-performance automotive engine parts.

Jiyuan Steel uses advanced heat treatment methods to improve the performance of its steel products, such as SAE 8620H and 42CrMo4, ensuring they meet the specific requirements for automotive engine components.

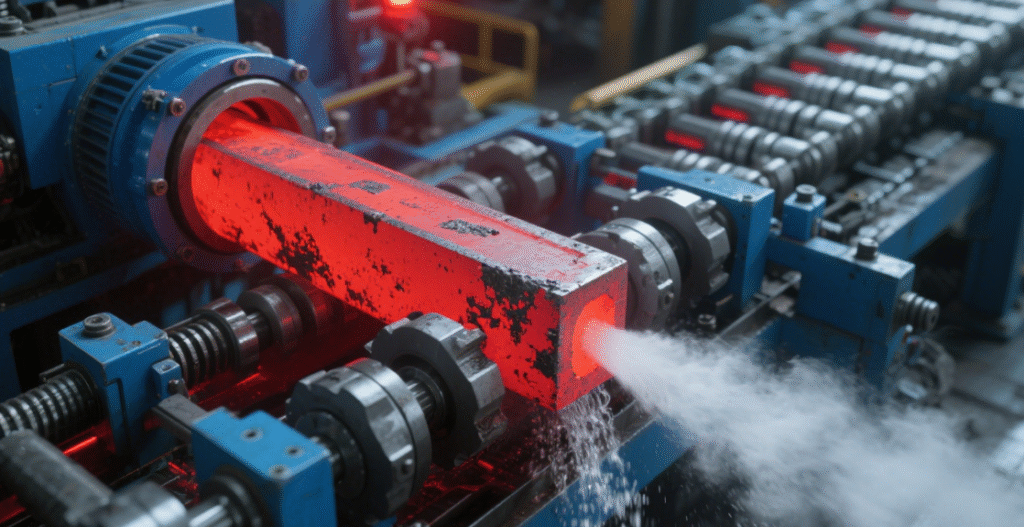

Steel Manufacturing Technologies for Engine Components

The steel manufacturing process is continually evolving, with new technologies emerging to improve the quality and performance of automotive engine parts. Modern steel production techniques, such as continuous casting and electroslag remelting, allow for greater control over the composition and microstructure of steel.

Continuous casting is a method in which molten steel is continuously poured into molds to form billets, which are then processed into finished products. This process ensures uniformity in the steel, reducing the risk of defects and improving the overall performance of engine components.

Electroslag remelting is used to produce high-quality steel with fewer impurities, making it ideal for critical engine components that require superior strength and reliability.

Jiyuan Steel’s advanced manufacturing technologies ensure that their products meet the highest standards for automotive applications. Their high-quality steel bars and precision processed steel are designed to provide optimal performance in engine parts, from crankshafts to gearbox components.

Table: Comparison of Steel Grades for Automotive Engine Parts

| Steel Grade | Composition | Key Features | Typical Applications |

|---|---|---|---|

| SAE 1045 | Carbon Steel (0.45% C) | High tensile strength, medium hardness | Crankshafts, shafts, gears |

| 42CrMo4 | Alloy Steel (Chromium, Molybdenum) | High wear resistance, high temperature strength | Crankshafts, camshafts, gears |

| SAE 8620H | Alloy Steel (Nickel, Chromium) | Excellent toughness and fatigue resistance | Transmission gears, connecting rods |

| SAE52100 | Bearing Steel (Chromium) | High hardness, wear resistance | Bearings, rollers, camshafts |

| SCM420H | Alloy Steel (Molybdenum, Nickel) | High strength and toughness | Engine blocks, gears, axles |

Conclusion

Steel manufacturing processes play a vital role in producing high-performance automotive engine parts. From selecting the right steel grade to employing advanced heat treatment methods and precision machining, every step in the steel production process contributes to the final product’s strength, durability, and efficiency. As a leading steel manufacturer, Henan Jiyuan Iron & Steel (Group) Co., Ltd. provides automotive manufacturers with high-quality steel solutions designed to meet the demanding requirements of modern engine components.

By leveraging cutting-edge steel production technologies, such as continuous casting and electroslag remelting, Jiyuan Steel ensures that its products, including SAE1045, 42CrMo4, and SAE8620H, meet the highest standards for automotive applications. Whether you’re looking for steel for engine blocks, crankshafts, or transmission components, Jiyuan’s wide range of high-performance steels offers the ideal solution for your needs.

For more information on our steel products and to receive a quote, feel free to contact us today.

FAQ

Q: What is the best steel grade for automotive engine components?

A: The best steel grade depends on the specific engine part. For example, SAE1045 is commonly used for crankshafts, while 42CrMo4 is ideal for camshafts and gears due to its high wear resistance and strength.

Q: How does heat treatment affect the strength of steel used in engine parts?

A: Heat treatment processes, such as quenching and tempering, are used to enhance the strength and toughness of steel. For engine parts, this ensures they can withstand high stresses and temperatures without failing.

Q: Why is precision machining important for automotive engine parts?f

A: Precision machining ensures that engine parts meet strict tolerances for performance and efficiency. It allows for the creation of parts with smooth surfaces and accurate dimensions, essential for optimal engine performance.

Q: How does Jiyuan Steel ensure the quality of its products?

A: Jiyuan Steel employs advanced manufacturing technologies, including continuous casting and electroslag remelting, to produce high-quality steel. Their strict quality control processes ensure that all products meet the highest standards for automotive engine applications.

If you want to learn more about this, you can click below: