Steel Round Bar: Material Types and Industrial Uses

Table of Contents

Introduction

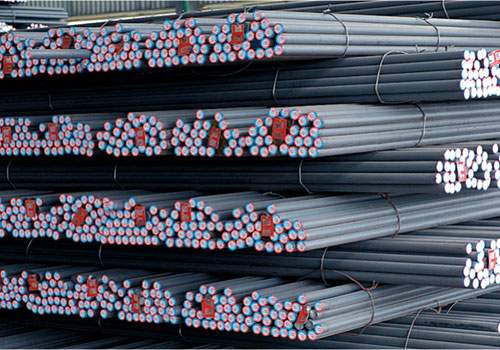

Steel round bars, also known as steel rods, are cylindrical metal bars widely used across construction, machinery, and industrial manufacturing. Their durability and versatility make them a critical material in applications ranging from structural frameworks to precision mechanical components. Engineers, architects, and procurement specialists often rely on steel round bars for projects that demand both strength and reliability.

Understanding Steel Round Bars

A steel round bar is a solid cylindrical steel piece, available in multiple diameters and lengths. These bars can be fabricated from carbon steel, stainless steel, alloy steel, or tool steel. Each material type offers unique mechanical and physical properties, allowing them to be applied in a wide array of industrial and structural contexts.

Why Steel Round Bars Are Essential

Steel round bars serve as foundational materials for building durable structures, machinery parts, and industrial tools. Their machinability, weldability, and adaptability make them indispensable in modern construction and manufacturing projects.

Types of Steel Round Bars

Carbon Steel Round Bars

Carbon steel round bars are widely recognized for their high strength and hardness, making them a go-to choice for general engineering and structural applications. Their composition typically contains a higher percentage of carbon, which directly contributes to enhanced tensile strength and wear resistance.

These bars are commonly used in machinery shafts, structural supports, and industrial fasteners. Due to their mechanical reliability and cost-effectiveness, carbon steel bars are often preferred in large-scale construction and manufacturing projects. However, their susceptibility to corrosion requires protective coatings, galvanization, or painting when exposed to harsh environments.

Example: In a mid-sized industrial factory, carbon steel round bars were used for conveyor shafts. Their strength allowed for high-speed operations, while protective coatings ensured durability in a humid environment.

Stainless Steel Round Bars

Stainless steel round bars are designed for environments that demand high corrosion resistance. The chromium content in stainless steel forms a protective oxide layer, preventing rust and chemical degradation.

These bars are essential in sectors such as food processing, medical equipment manufacturing, and chemical plant machinery. Although the cost is higher than carbon steel, the long-term benefits—reduced maintenance, enhanced longevity, and resistance to corrosion—justify the investment.

Real-World Application: Stainless steel bars are often used in food-grade machinery. For example, in a dairy plant, stainless steel round bars were utilized in roller shafts where constant exposure to moisture and cleaning agents occurs, ensuring hygiene and long-term performance.

Alloy Steel Round Bars

Alloy steel bars contain additional elements such as nickel, chromium, molybdenum, or vanadium to enhance strength, hardness, and thermal resistance. This makes them ideal for demanding applications where both mechanical performance and durability under stress are required.

Typical uses include automotive components, aerospace parts, heavy-duty machinery, and structural elements subjected to dynamic loads. Alloy steel round bars provide a balance between strength and toughness, making them versatile for high-performance applications.

Example: In a car manufacturing plant, alloy steel round bars were used for high-strength drive shafts, allowing the components to withstand torque and vibration during operation.

Tool Steel Round Bars

Tool steel round bars are engineered for maximum hardness, wear resistance, and dimensional stability. They are primarily used in the production of cutting tools, dies, molds, and high-precision machinery parts.

Their hardness allows them to maintain sharp edges and resist deformation under extreme loads or high temperatures. However, tool steel has limited corrosion resistance, which must be considered in humid or chemical-prone environments.

Example: Tool steel round bars are commonly used to manufacture punch dies in a metal stamping factory. Their superior hardness ensures precise cuts and long-lasting performance, even under repetitive high-pressure operations.

Common Specifications of Steel Round Bars

Diameter and Length Options

Steel round bars are available in a wide range of diameters and lengths to suit different industrial requirements. Small diameters (6–20 mm) are ideal for light-duty mechanical parts, fittings, or rods in machinery. Medium diameters (20–50 mm) are used in general structural components and standard machinery applications. Large diameters (50 mm+) cater to heavy industrial equipment such as presses, shafts, or reinforced structural columns.

Standard lengths are typically 6 or 12 meters. However, custom lengths are often produced for specific projects, allowing precise adaptation to design needs and reducing waste.

Comparison Concept: While a 20 mm carbon steel bar may serve a simple mechanical shaft, a 60 mm alloy steel bar would be more suitable for a heavy-duty drive shaft due to higher stress tolerance.

Surface Finish Variations

The surface finish of steel round bars affects both aesthetic appeal and functional performance.

- Hot-Rolled Bars: Economical and commonly used in structural and general engineering applications. They may have slight surface imperfections but are cost-effective for large-scale projects.

- Cold-Drawn Bars: Provide high dimensional accuracy and smoother surfaces, making them ideal for precision engineering or mechanical components that require tight tolerances.

- Polished Bars: Used when surface quality is critical, such as in decorative components or precision machinery. Polishing improves corrosion resistance slightly and ensures smooth contact surfaces in moving parts.

Example: Cold-drawn stainless steel round bars were used in a precision gearbox manufacturing process. The smooth surface reduced friction and wear, improving gear longevity and performance.

Material and Mechanical Properties Table

| Material Type | Diameter Range (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Typical Applications |

|---|---|---|---|---|---|

| Carbon Steel | 6–100 | 400–700 | 250–500 | 120–200 | Structural parts, shafts, machinery |

| Stainless Steel | 6–80 | 500–850 | 300–600 | 150–220 | Food equipment, chemical plants |

| Alloy Steel | 10–100 | 600–1000 | 350–700 | 180–300 | Automotive, aerospace, heavy machinery |

| Tool Steel | 10–50 | 800–1200 | 500–900 | 250–450 | Cutting tools, molds, dies |

This table helps users quickly understand the mechanical capabilities, diameters, and common applications of each steel type.

Standards and Compliance

International Standards for Steel Round Bars

Steel round bars must comply with recognized standards to ensure consistency and performance. ASTM standards (e.g., ASTM A36, AISI 1045) define chemical composition, tensile strength, and dimensional tolerances. ISO standards provide global uniformity, while DIN standards from Germany emphasize quality and reliability.

Domestic Standards in China

Chinese standards such as GB/T 699, GB/T 3077, and GB/T 173-2008 define carbon, alloy, and stainless steel round bars respectively. Compliance with these standards ensures material reliability and simplifies procurement in industrial projects.

Why Standards Matter

Adhering to recognized standards reduces risk, ensures performance, and allows for accurate comparison between suppliers. Standardization guarantees that a steel round bar meets both mechanical and chemical property requirements necessary for specific applications.

Mechanical Properties and Performance

Tensile Strength and Yield Strength

Tensile strength determines the maximum load a steel round bar can bear, while yield strength identifies the stress level at which permanent deformation occurs.

Hardness and Wear Resistance

Hardness defines the steel’s resistance to surface indentation and wear. Tool steel bars are particularly designed to provide high hardness for cutting and industrial tool applications.

Heat Treatment Impacts

Annealing softens steel for better machinability. Quenching and tempering improve strength and hardness, making the bars suitable for demanding industrial environments.

Comparing Carbon Steel vs Stainless Steel

While carbon steel is economical and strong, stainless steel provides superior corrosion resistance. Selecting the right material involves balancing cost, mechanical performance, and environmental durability.

Applications of Steel Round Bars

Industrial Machinery Components

Steel round bars are used for shafts, gears, and fasteners, providing the structural backbone of machinery and equipment.

Construction Structures

Carbon steel bars reinforce concrete structures and serve as key elements in beams, columns, and support frameworks.

Automotive and Aerospace

Alloy steel bars are integral in producing durable automotive parts and aerospace components, ensuring high performance under stress.

Real-World Example

In a recent industrial project, a factory required precision shafts for high-speed machinery. Cold-drawn alloy steel round bars were selected for their tight dimensional tolerances and high tensile strength, resulting in equipment that performed reliably under continuous operation for over three years.

How to Select the Right Steel Round Bar

- Material Considerations: Carbon steel for general structural applications, stainless steel for corrosion resistance, and alloy steel for high-strength applications.

- Size and Diameter Selection: Match mechanical requirements and load-bearing needs.

- Surface Finish Choice: Hot-rolled for general use, cold-drawn or polished for precision or aesthetic purposes.

- Standards and Certifications: Verify ASTM, ISO, or GB compliance to ensure performance.

Conclusion

Steel round bars are versatile, high-performance materials essential for construction, machinery, automotive, and industrial applications. By understanding their material types, specifications, standards, and mechanical properties, you can make informed decisions for any project.

Need specific selection guidance? Contact our engineers today for personalized advice and recommendations to choose the perfect steel round bar for your application.

FAQ

What is a steel round bar, and how is it different from a steel rod?

Steel round bars are typically solid, cylindrical, and thicker than rods. Rods may refer to thinner bars or reinforcement bars used in concrete construction.

How do I know which steel round bar is suitable for my project?

Consider the material type, diameter, strength requirements, and environmental conditions. Comparing carbon, stainless, and alloy steels helps determine the best option.

Can steel round bars be used for both structural and mechanical purposes?

Yes, depending on material type and specifications. Carbon steel bars are common in construction, while alloy and tool steels are preferred for precision machinery.

What surface finish should I choose?

Hot-rolled bars are suitable for general structures. Cold-drawn bars are ideal for machining and mechanical components, and polished bars are used for high-precision or decorative applications.

Are international standards necessary for selecting steel round bars?

Yes. Standards such as ASTM, ISO, and DIN ensure consistent quality, chemical composition, and mechanical performance.

How can I verify the quality of steel round bars?

Request material certificates, check mechanical properties, and confirm compliance with relevant standards. Real-world testing may also be conducted for critical applications.