Top 7 Custom Steel Billet Shapes for Heavy Industry

Table of Contents

Introduction

In heavy industries, custom steel billets play a pivotal role in ensuring the efficiency, durability, and strength of industrial machinery and structures. Whether it’s construction, automotive manufacturing, or energy production, the need for customized steel billet shapes tailored to specific applications is paramount. These billets serve as the foundation for products that require precision, strength, and reliability under extreme conditions.

This blog will explore the top 7 custom steel billet shapes used in heavy industry applications, providing insights into their importance and how they improve the manufacturing process. We will also discuss how choosing the right steel billet shape can impact the overall performance of industrial machinery and contribute to long-term cost savings.

Why Custom Steel Billet Shapes Are Essential for Heavy Industry

Custom steel billets are not just about size—they are about the precise shape and structure that suit specific industry requirements. Off-the-shelf billets may not offer the same performance as those designed with unique applications in mind. By customizing the billet shape, industries can ensure they are getting the maximum strength, durability, and efficiency out of their machinery and structures.

In heavy industries, custom steel billets are critical for:

- Improved Performance: Precision-engineered billets contribute to better performance under high stress and harsh environments.

- Durability: The right billet shape can improve the longevity of heavy machinery and reduce the need for costly repairs or replacements.

- Efficiency: Custom billets help optimize the manufacturing process, reducing waste and material costs.

Top 7 Custom Steel Billet Shapes for Heavy Industry Applications

Below are the top 7 custom steel billet shapes used across various sectors in heavy industry:

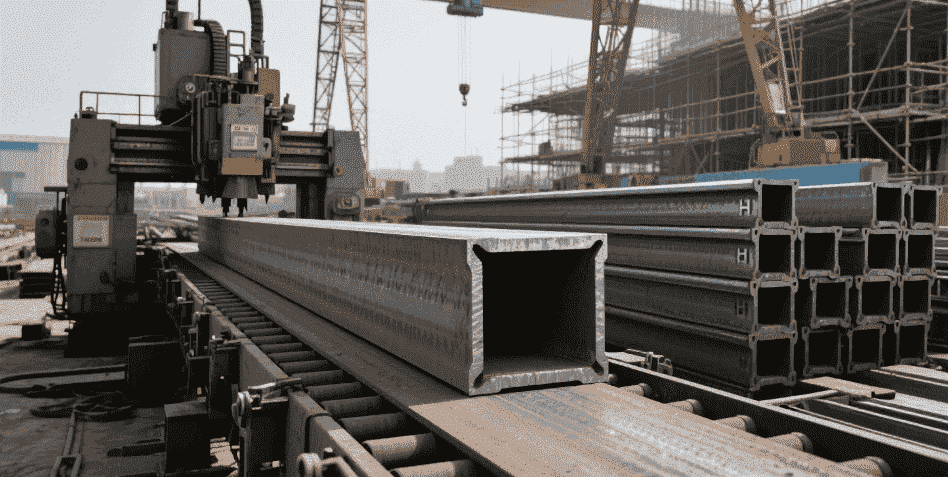

1. Rectangular Steel Billets for Construction and Manufacturing

Rectangular billets are one of the most common shapes used in construction and manufacturing due to their versatility. These billets can be easily processed into beams, plates, and other components that require structural integrity. The rectangular shape allows for easy handling and further processing, making them a top choice in industries like construction and heavy machinery.

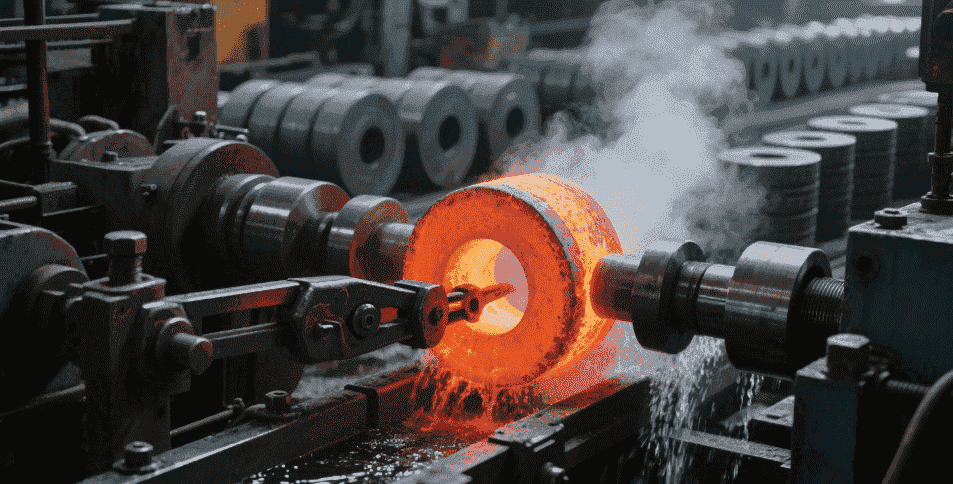

2. Round Steel Billets for Rolling and Forging

Round billets are highly favored in the forging and rolling processes due to their uniformity. The round shape facilitates even distribution of heat during the forging process, making it ideal for producing components like shafts, gears, and axles. This shape is particularly useful in the automotive and aerospace industries.

3. Square Steel Billets for Machine Parts and Structural Support

Square billets are ideal for manufacturing machine parts and structural support beams. They offer strength in all directions, making them highly effective for creating parts that need to bear significant loads. Their uniform shape also makes them easier to machine, ensuring high precision in final products.

4. Hexagonal Steel Billets for Specialized Manufacturing

Hexagonal billets are custom-made for industries that require specific shapes, such as the automotive and construction sectors. Their unique shape is ideal for producing parts like bolts, nuts, and fasteners, where a specific fit is necessary. Hexagonal billets help reduce machining time and enhance the overall product fit.

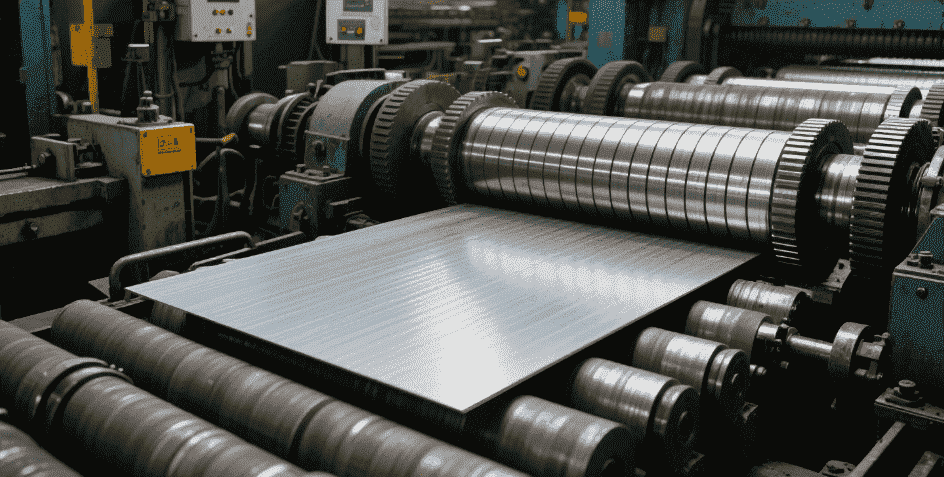

5. Flat Steel Billets for Sheet Metal Production

Flat billets are used extensively in sheet metal production due to their ability to be transformed into thin sheets with a consistent thickness. These billets are critical in the automotive and manufacturing industries, where high-volume sheet metal parts are needed for body panels, frames, and more.

6. Tapered Steel Billets for Aerospace and Heavy Equipment

Tapered billets are designed with one end larger than the other, making them ideal for use in industries like aerospace and heavy equipment manufacturing. They are especially useful for producing components that require specific tapering for strength and aerodynamics, such as turbine blades or structural components.

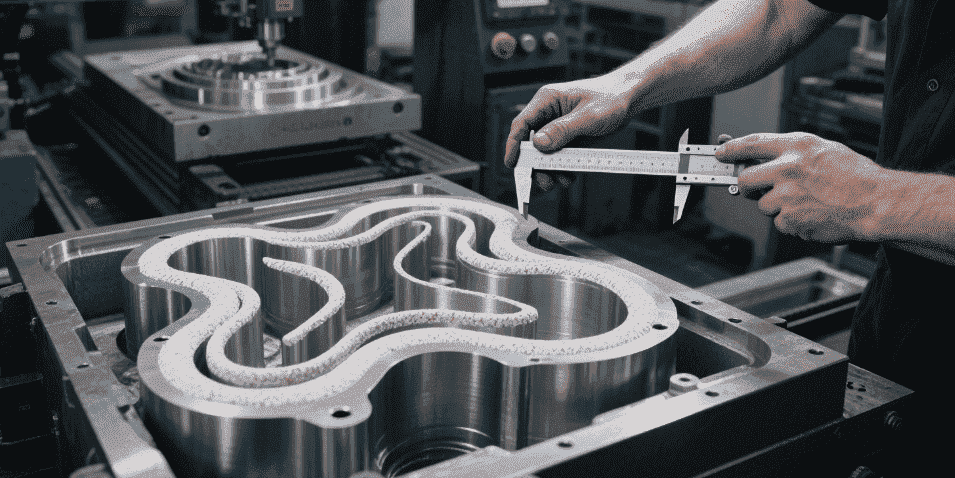

7. Custom Shaped Steel Billets for High-Precision Applications

Some industries require highly specialized billet shapes tailored to their unique needs. For example, custom-shaped billets may be used to create parts for medical equipment, military hardware, or other precision-driven industries. These billets often involve complex geometries and are crafted to meet tight tolerance requirements.

The Importance of Choosing the Right Steel Billet Shape

Selecting the right custom steel billet shape is crucial for ensuring optimal performance in heavy industries. The wrong choice can result in manufacturing delays, increased costs, and reduced efficiency. Here’s why:

- Cost-Efficiency: Custom billets help minimize material waste, reducing overall costs.

- Product Quality: The right shape ensures that the billet can be processed effectively, leading to higher-quality finished products.

- Application-Specific Strength: Different shapes are designed to provide strength and durability in specific conditions, such as high heat or pressure.

How Custom Steel Billet Shapes Impact Heavy Industry Equipment

The shape of the steel billet directly influences the performance of heavy industry equipment. For example:

- Round billets used in forging are perfect for producing machine components that need to withstand rotational forces.

- Rectangular billets are ideal for large structural components, providing the necessary strength for critical support.

- Square billets ensure that the load-bearing parts of heavy machinery maintain structural integrity in all directions.

By using custom steel billets, industries can enhance the durability, performance, and safety of their equipment, leading to fewer breakdowns and lower maintenance costs.

Comparison of Steel Billet Shapes and Their Applications

| Steel Billet Shape | Common Applications | Key Benefits | Industries |

|---|---|---|---|

| Rectangular | Construction beams, structural plates | Versatile, easy to process, high strength | Construction, Manufacturing |

| Round | Shafts, gears, axles | Uniform heat distribution, ideal for forging | Automotive, Aerospace |

| Square | Machine parts, structural beams | Strength in all directions, easy to machine | Heavy Machinery, Aerospace |

| Hexagonal | Bolts, nuts, fasteners | Reduced machining time, enhanced fit | Automotive, Manufacturing |

| Flat | Sheet metal production | Consistent thickness, ideal for high-volume production | Automotive, Manufacturing |

| Tapered | Turbine blades, structural components | Strength and aerodynamics for specialized applications | Aerospace, Heavy Equipment |

| Custom Shaped | Precision parts (medical, military) | Tailored geometries, high precision | Medical, Military, Aerospace |

Conclusion

Custom steel billet shapes are essential for optimizing manufacturing processes and ensuring the longevity and performance of heavy industry equipment. From rectangular billets for construction to round billets for automotive parts, the right shape can make a significant difference in both product quality and production efficiency.

By understanding the unique needs of your industry and selecting the appropriate billet shape, you can achieve better performance, cost savings, and enhanced durability for your machinery and structures. Whether you are in the automotive, aerospace, or construction industry, custom steel billets tailored to your specific requirements are an investment that will pay off in the long run.

FAQ

Why is the shape of a steel billet important in heavy industries?

The shape of a steel billet determines how it can be processed, its load-bearing capacity, and how efficiently it can be integrated into manufacturing processes. The right billet shape ensures better performance, reduced waste, and higher-quality final products.

How do custom steel billets contribute to cost savings?

Custom steel billets reduce material waste by ensuring that the billet is the optimal size and shape for the desired application. This helps to minimize scrap material and processing time, leading to overall cost savings in production.

Can I order custom steel billets in any shape?

Yes, many suppliers offer custom steel billet manufacturing services where you can specify the exact shape, size, and material composition needed for your specific application. However, it’s important to ensure that the chosen shape is practical for your manufacturing process.

What industries benefit most from custom steel billets?

Industries such as construction, automotive, aerospace, heavy equipment, and manufacturing benefit most from custom steel billets due to the high demand for specialized, high-performance components.

What are the key factors to consider when selecting a custom steel billet shape?

When selecting a custom steel billet shape, consider factors such as the application requirements (strength, size, and geometry), the type of material used, processing methods, and the desired performance under specific operating conditions. The right shape ensures that the billet can be processed efficiently, with minimal waste and maximum strength.

How do custom steel billets affect the quality of finished products?

Custom steel billets are designed to meet specific needs, which ensures that they perform better under the unique conditions of heavy industries. The right billet shape minimizes defects and inconsistencies in the final product, contributing to higher quality, better durability, and improved reliability of components.

Are there any challenges in producing custom steel billets for heavy industries?

Yes, producing custom steel billets requires precise engineering and advanced manufacturing techniques. Challenges may include achieving the desired dimensions and shapes within tight tolerances, as well as managing production costs. Additionally, ensuring that the billet shape can be easily integrated into the rest of the manufacturing process can be complex.

How does the shape of the billet influence the final machining process?

The shape of the steel billet directly impacts the efficiency of the machining process. Billets that are already close to the desired final shape require less machining, saving time and reducing material loss. Conversely, more complex shapes may require additional machining, increasing production time and costs.

Can custom steel billets improve the sustainability of manufacturing processes?

Yes, custom steel billets can enhance sustainability by reducing material waste. By creating billets tailored to specific applications, manufacturers can minimize excess scrap, optimize resource use, and lower overall energy consumption during processing, contributing to a more eco-friendly production cycle.

What types of steel alloys are typically used in custom steel billets?

The choice of steel alloy for custom billets depends on the application requirements. Common alloys include carbon steel, alloy steel, stainless steel, and tool steel, each offering different properties like strength, corrosion resistance, and machinability. Choosing the right alloy is crucial for ensuring that the billet performs as expected in the final application.

How do custom steel billets contribute to the safety of heavy industry equipment?

Custom steel billets are engineered to provide specific strength and durability characteristics, making them ideal for high-stress applications. By using the right billet shape, heavy industry equipment can be designed to withstand extreme conditions, reducing the risk of failure and improving overall safety.

How does the size of the custom steel billet affect the manufacturing process?

The size of the steel billet directly affects its processability. Larger billets may require more energy and time to heat and shape, while smaller billets are often easier to handle and faster to process. Custom sizes ensure that the billet is not too large or too small for its intended use, optimizing both material usage and processing time.